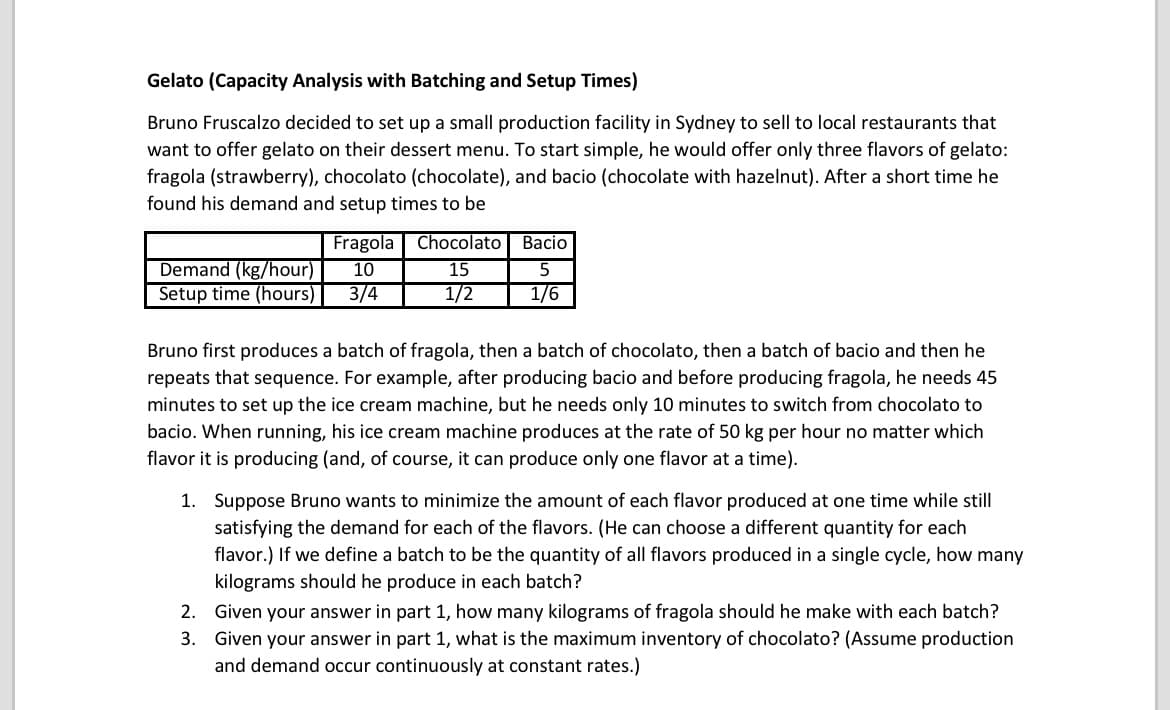

Gelato (Capacity Analysis with Batching and Setup Times) Bruno Fruscalzo decided to set up a small production facility in Sydney to sell to local restaurants that want to offer gelato on their dessert menu. To start simple, he would offer only three flavors of gelato: fragola (strawberry), chocolato (chocolate), and bacio (chocolate with hazelnut). After a short time he found his demand and setup times to be Fragola| Chocolato 10 3/4 Вacio Demand (kg/hour) Setup time (hours)| 15 1/2 1/6 Bruno first produces a batch of fragola, then a batch of chocolato, then a batch of bacio and then he repeats that sequence. For example, after producing bacio and before producing fragola, he needs 45 minutes to set up the ice cream machine, but he needs only 10 minutes to switch from chocolato to bacio. When running, his ice cream machine produces at the rate of 50 kg per hour no matter which flavor it is producing (and, of course, it can produce only one flavor at a time). 1. Suppose Bruno wants to minimize the amount of each flavor produced at one time while still satisfying the demand for each of the flavors. (He can choose a different quantity for each flavor.) If we define a batch to be the quantity of all flavors produced in a single cycle, how many kilograms should he produce in each batch? 2. Given your answer in part 1, how many kilograms of fragola should he make with each batch? 3. Given your answer in part 1, what is the maximum inventory of chocolato? (Assume production and demand occur continuously at constant rates.)

Gelato (Capacity Analysis with Batching and Setup Times) Bruno Fruscalzo decided to set up a small production facility in Sydney to sell to local restaurants that want to offer gelato on their dessert menu. To start simple, he would offer only three flavors of gelato: fragola (strawberry), chocolato (chocolate), and bacio (chocolate with hazelnut). After a short time he found his demand and setup times to be Fragola| Chocolato 10 3/4 Вacio Demand (kg/hour) Setup time (hours)| 15 1/2 1/6 Bruno first produces a batch of fragola, then a batch of chocolato, then a batch of bacio and then he repeats that sequence. For example, after producing bacio and before producing fragola, he needs 45 minutes to set up the ice cream machine, but he needs only 10 minutes to switch from chocolato to bacio. When running, his ice cream machine produces at the rate of 50 kg per hour no matter which flavor it is producing (and, of course, it can produce only one flavor at a time). 1. Suppose Bruno wants to minimize the amount of each flavor produced at one time while still satisfying the demand for each of the flavors. (He can choose a different quantity for each flavor.) If we define a batch to be the quantity of all flavors produced in a single cycle, how many kilograms should he produce in each batch? 2. Given your answer in part 1, how many kilograms of fragola should he make with each batch? 3. Given your answer in part 1, what is the maximum inventory of chocolato? (Assume production and demand occur continuously at constant rates.)

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

How can i solve this exercise?

Transcribed Image Text:Gelato (Capacity Analysis with Batching and Setup Times)

Bruno Fruscalzo decided to set up a small production facility in Sydney to sell to local restaurants that

want to offer gelato on their dessert menu. To start simple, he would offer only three flavors of gelato:

fragola (strawberry), chocolato (chocolate), and bacio (chocolate with hazelnut). After a short time he

found his demand and setup times to be

Fragola Chocolato

Вacio

Demand (kg/hour)

Setup time (hours)

10

15

5

3/4

1/2

1/6

Bruno first produces a batch of fragola, then a batch of chocolato, then a batch of bacio and then he

repeats that sequence. For example, after producing bacio and before producing fragola, he needs 45

minutes to set up the ice cream machine, but he needs only 10 minutes to switch from chocolato to

bacio. When running, his ice cream machine produces at the rate of 50 kg per hour no matter which

flavor it is producing (and, of course, it can produce only one flavor at a time).

1. Suppose Bruno wants to minimize the amount of each flavor produced at one time while still

satisfying the demand for each of the flavors. (He can choose a different quantity for each

flavor.) If we define a batch to be the quantity of all flavors produced in a single cycle, how many

kilograms should he produce in each batch?

2. Given your answer in part 1, how many kilograms of fragola should he make with each batch?

3. Given your answer in part 1, what is the maximum inventory of chocolato? (Assume production

and demand occur continuously at constant rates.)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.