ions. Show the principal stresses dearty in a stress element fors (Use only the formula sheet provided in the beginni ce and comesponding stress values and coresponding stress values s after decimal pont using Gerber criterion after decimal point

ions. Show the principal stresses dearty in a stress element fors (Use only the formula sheet provided in the beginni ce and comesponding stress values and coresponding stress values s after decimal pont using Gerber criterion after decimal point

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter1: Tension, Compression, And Shear

Section: Chapter Questions

Problem 1.9.18P: The piston in an engine is attached to a connecting rod AB, which in turn is connected to a crank...

Related questions

Question

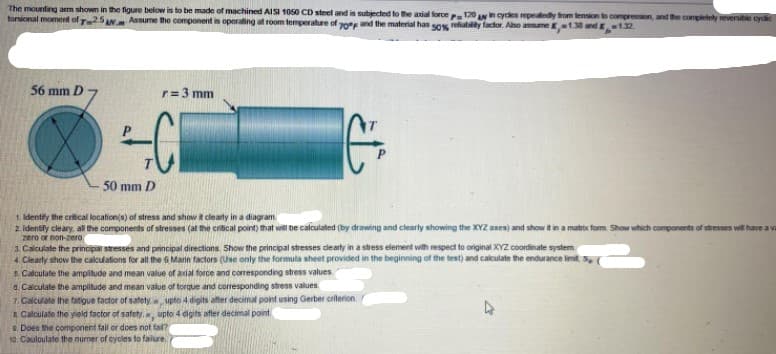

Transcribed Image Text:The mounting arm shown in the figure below is to be made of machined AISI 1050 CD steel and is subjected to the aial force 120 An cyces repeatedy from tension to compression, and the completely reversitie cycd

torsional moment of T25AN Assume the component is operating at room temperature of 0 and the material has sos refiablity factor. Aso asume K138 and-132

56 mm D

r=3 mm

%3D

50 mm D

1. Identity the critical location(s) of stress and show it clearly in a diagram

2 Identify cleary, all the components of stresses (at the critical point) that will be calculated (by drawing and clearly showing the XYZ axes) and show it in a matrix form Show which components of stresses will have a va

zero or non-zero

3. Calculate the principar stresses and principal directions. Show the principal stresses dearty in a stress element with respect to original XYZ coordinate system

4. Clearly show the calculations for all the 6 Marin factors (Use only the formula sheet provided in the beginning of the test) and calculate the endurance limit, s,

5 Calculate the amplitude and mean value of axial force and coresponding stress values

a. Calculate the ampitude and mean value of torque and corresponding stress values.

7. Calculate the fatigue factor of satety upto 4 digits after decimal point using Gerber criterion

8 Calculate the yield factor of safety, upto 4 digits after decimal point

0. Does the component fail or does not fal?

10. Cauloulate the numer of cycles to failure

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning