ons of a JIT relationship from a supplier’s point of view. 2) Identify the pros and cons of a JIT relationship from a buyer’s point of

ons of a JIT relationship from a supplier’s point of view. 2) Identify the pros and cons of a JIT relationship from a buyer’s point of

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

1) Identify the pros and cons of a JIT relationship from a supplier’s point of view.

2) Identify the pros and cons of a JIT relationship from a buyer’s point of view.

3) What factors should Dixon and D&S consider before making a decision on this relationship?

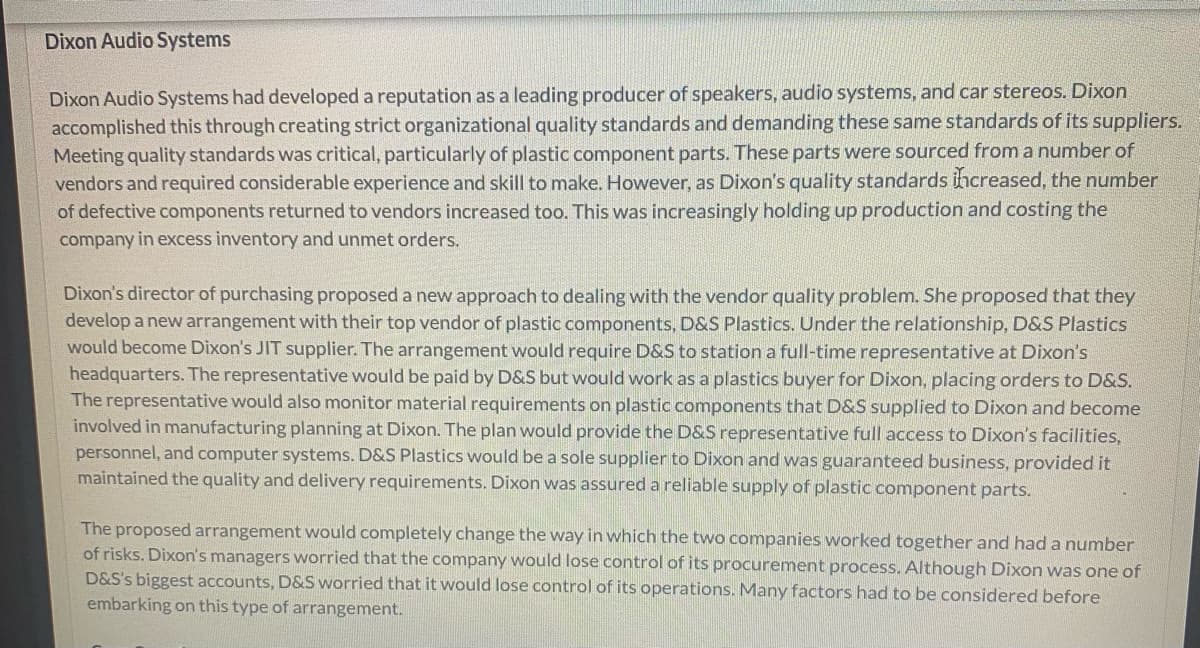

Transcribed Image Text:Dixon Audio Systems

Dixon Audio Systems had developed a reputation as a leading producer of speakers, audio systems, and car stereos. Dixon

accomplished this through creating strict organizational quality standards and demanding these same standards of its suppliers.

Meeting quality standards was critical, particularly of plastic component parts. These parts were sourced from a number of

vendors and required considerable experience and skill to make. However, as Dixon's quality standards ihcreased, the number

of defective components returned to vendors increased too. This was increasingly holding up production and costing the

company in excess inventory and unmet orders.

Dixon's director of purchasing proposed a new approach to dealing with the vendor quality problem. She proposed that they

develop a new arrangement with their top vendor of plastic components, D&S Plastics. Under the relationship, D&S Plastics

would become Dixon's JIT supplier. The arrangement would require D&S to station a full-time representative at Dixon's

headquarters. The representative would be paid by D&S but would work as a plastics buyer for Dixon, placing orders to D&S.

The representative would also monitor material requirements on plastic components that D&S supplied to Dixon and become

involved in manufacturing planning at Dixon. The plan would provide the D&S representative full access to Dixon's facilities,

personnel, and computer systems. D&S Plastics would be a sole supplier to Dixon and was guaranteed business, provided it

maintained the quality and delivery requirements. Dixon was assured a reliable supply of plastic component parts.

The proposed arrangement would completely change the way in which the two companies worked together and had a number

of risks. Dixon's managers worried that the company would lose control of its procurement process. Although Dixon was one of

D&S's biggest accounts, D&S worried that it would lose control of its operations. Many factors had to be considered before

embarking on this type of arrangement.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.