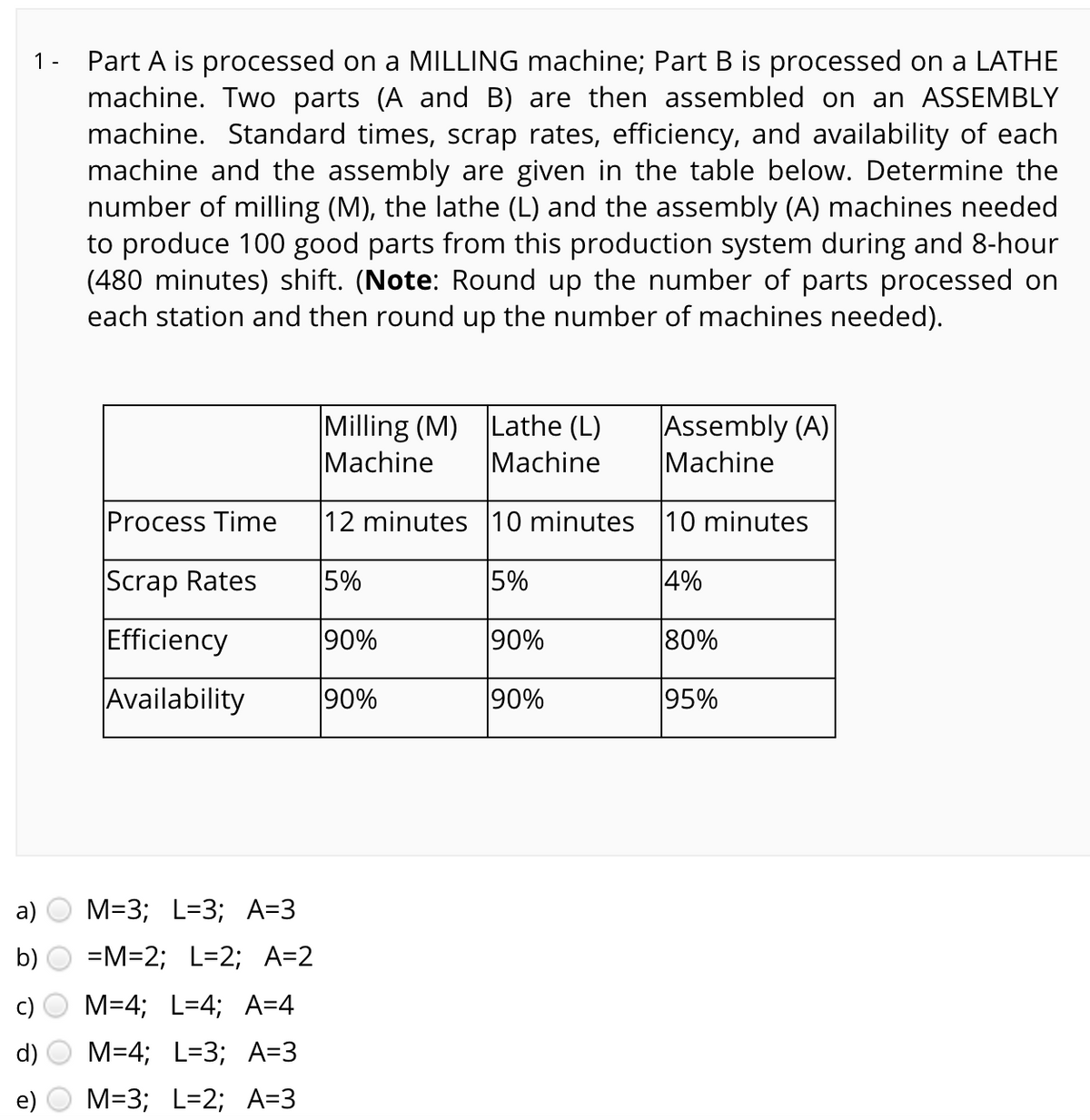

Part A is processed on a MILLING machine; Part B is processed on a LATHE machine. Two parts (A and B) are then assembled on an ASSEMBLY machine. Standard times, scrap rates, efficiency, and availability of each machine and the assembly are given in the table below. Determine the number of milling (M), the lathe (L) and the assembly (A) machines needed to produce 100 good parts from this production system during and 8-hour (480 minutes) shift. (Note: Round up the number of parts processed on each station and then round up the number of machines needed)

Part A is processed on a MILLING machine; Part B is processed on a LATHE machine. Two parts (A and B) are then assembled on an ASSEMBLY machine. Standard times, scrap rates, efficiency, and availability of each machine and the assembly are given in the table below. Determine the number of milling (M), the lathe (L) and the assembly (A) machines needed to produce 100 good parts from this production system during and 8-hour (480 minutes) shift. (Note: Round up the number of parts processed on each station and then round up the number of machines needed)

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter4: Linear Programming Models

Section: Chapter Questions

Problem 111P

Related questions

Question

Part A is processed on a MILLING machine; Part B is processed on a LATHE machine. Two parts (A and B) are then assembled on an ASSEMBLY machine. Standard times, scrap rates, efficiency, and availability of each machine and the assembly are given in the table below. Determine the number of milling (M), the lathe (L) and the assembly (A) machines needed to produce 100 good parts from this production system during and 8-hour (480 minutes) shift. (Note: Round up the number of parts processed on each station and then round up the number of machines needed).

Transcribed Image Text:Part A is processed on a MILLING machine; Part B is processed on a LATHE

machine. Two parts (A and B) are then assembled on an ASSEMBLY

machine. Standard times, scrap rates, efficiency, and availability of each

machine and the assembly are given in the table below. Determine the

number of milling (M), the lathe (L) and the assembly (A) machines needed

to produce 100 good parts from this production system during and 8-hour

(480 minutes) shift. (Note: Round up the number of parts processed on

each station and then round up the number of machines needed).

1 -

Milling (M) Lathe (L)

Machine

|Мachine

Assembly (A)

Machine

Process Time

12 minutes 10 minutes 10 minutes

Scrap Rates

5%

5%

4%

Efficiency

90%

90%

80%

Availability

90%

90%

95%

a)

М-3; L33; А-3

b)

=M=2; L=2; A=2

М-4; L34; А-4

d)

M=4; L=3; A=3

M=3; L=2; A=3

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, marketing and related others by exploring similar questions and additional content below.Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,