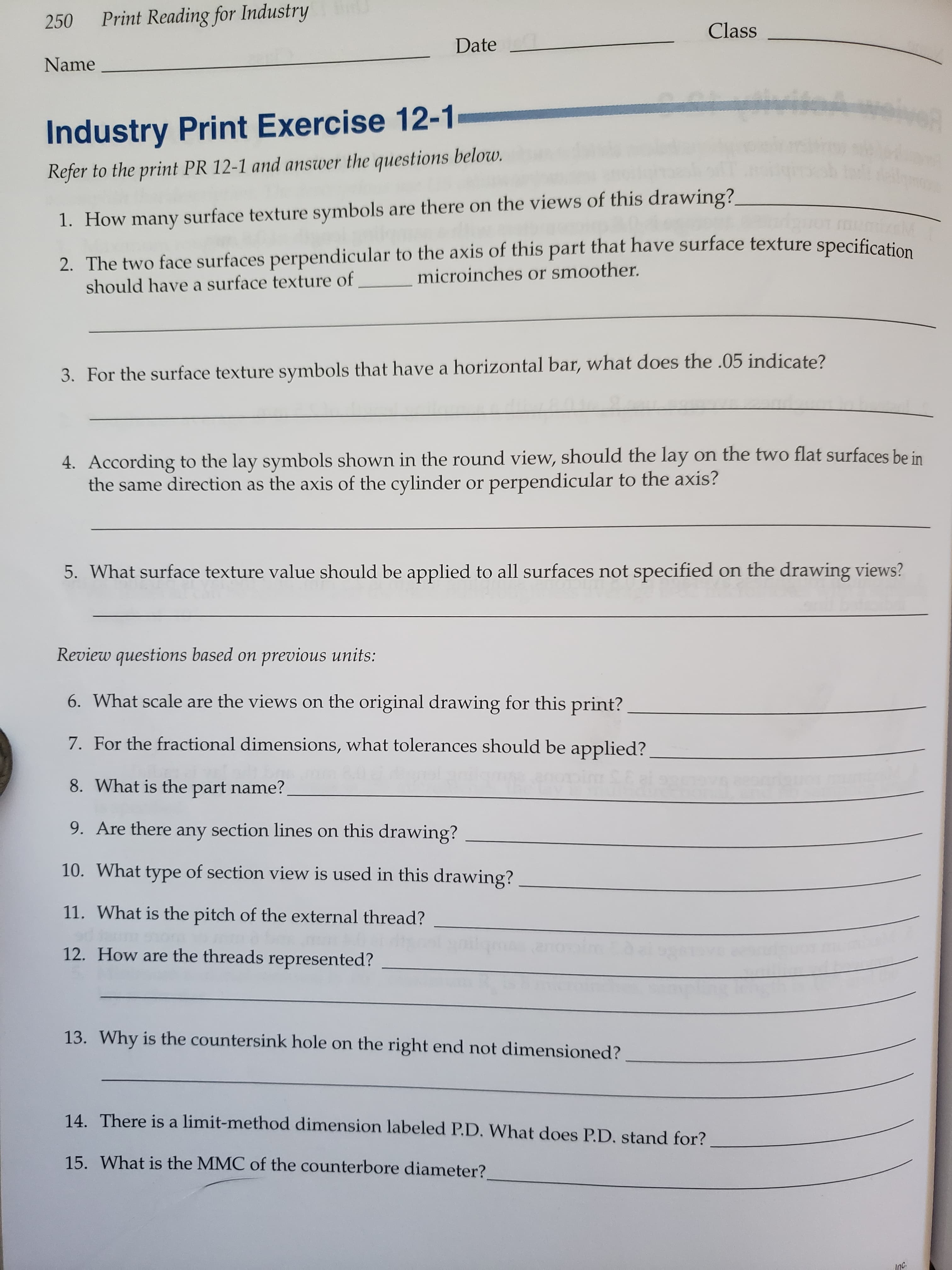

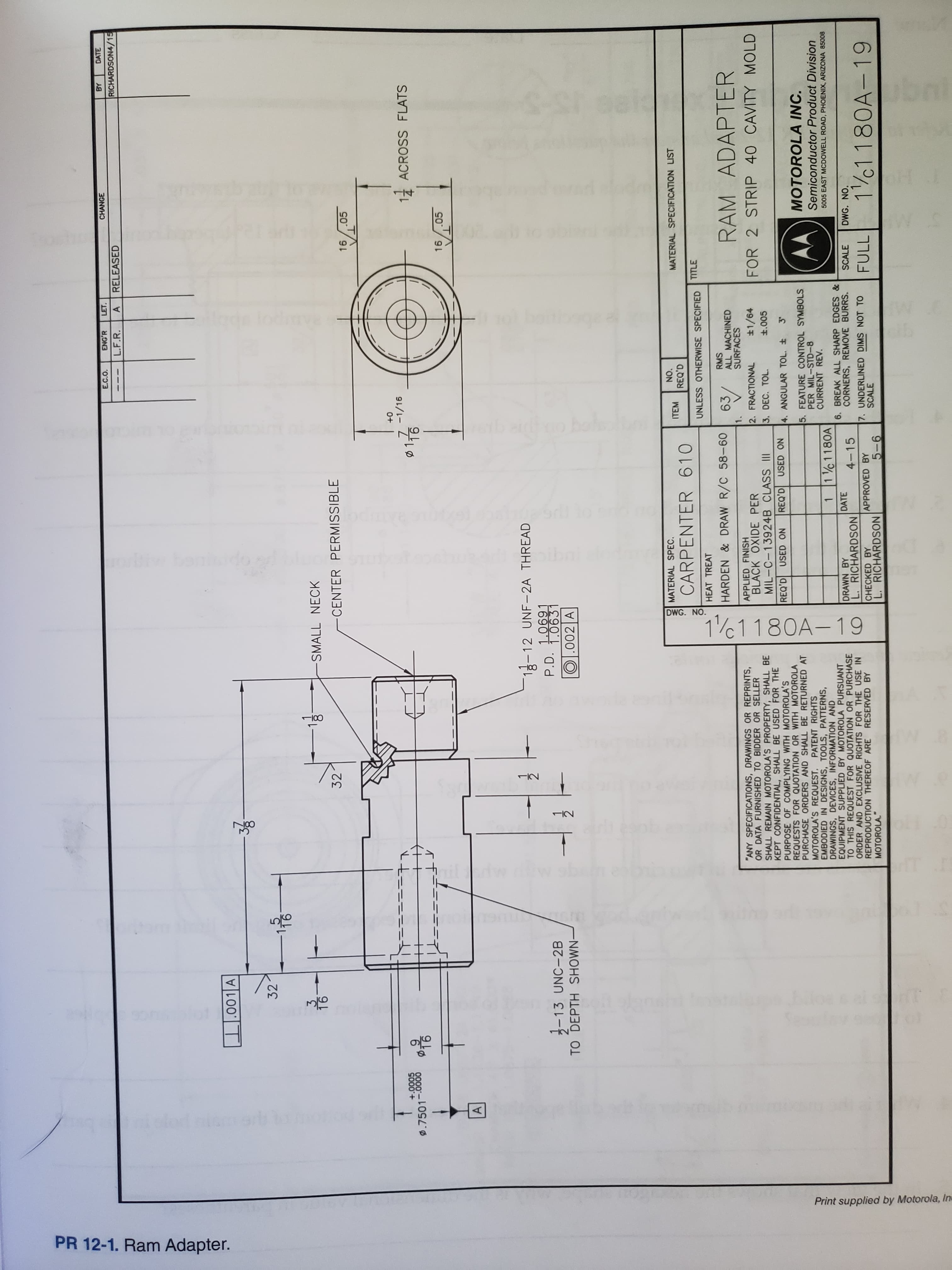

Print Reading for Industry 250 Class Date Name Industry Print Exercise 12-1 Refer to the print PR 12-1 and answer the questions below. 1. How many surface texture symbols are there on the views of this drawing? 2. The two face surfaces perpendicular to the axis of this part that have surface texture specification microinches or smoother. should have a surface texture of 3. For the surface texture symbols that have a horizontal bar, what does the .05 indicate? on the two flat surfaces be in 4. According to the lay symbols shown in the round view, should the lay the same direction as the axis of the cylinder or perpendicular to the axis? 5. What surface texture value should be applied to all surfaces not specified on the drawing views? Review questions based on previous units: 6. What scale are the views on the original drawing for this print? 7. For the fractional dimensions, what tolerances should be applied? 8. What is the part name? 9. Are there any section lines on this drawing? 10. What type of section view is used in this drawing? 11. What is the pitch of the external thread? 12. How are the threads represented? 13. Why is the countersink hole on the right end not dimensioned? 14. There is a limit-method dimension labeled P.D. What does P.D. stand for? 15. What is the MMC of the counterbore diameter? Inc. DWG. NO. 11180A-19 1100 12 oe & al ectT Print supplied by Motorola, In PR 12-1. Ram Adapter. E.C.O. ENG'R LET. CHANGE BY DATE L.F.R. RELEASED RICHARDSON4/15 .001 A 32 3 16 -SMALL NECK 32 -CENTER PERMISSIBLE .05 T 0+ -1/16 +.0005 D.7501-0000 1: 116 ACROSS FLATS + 왕이 16.05 A 12-12 UNF-2A THREAD P.D. 1.0691 1.0631 -13 UNC-2B TO DEPTH SHOWN - O.002 A MATERIAL SPEC. NO. ITEM MATERIAL SPECIFICATION LIST REQ'D CARPENTER 610 UNLESS OTHERWISE SPECIFIED TITLE HEAT TREAT RMS ALL MACHINED SURFACES HARDEN& DRAW R/C 58-60 63 RAM ADAPTER 1. "ANY SPECIFICATIONS, DRAWINGS OR REPRINTS, OR DATA FURNISHED TO BIDDER OR SELLER SHALL REMAIN MOTOROLA'S PROPERTY, SHALL BE KEPT CONFIDENTIAL, SHALL BE USED FOR THE PURPOSE OF COMPLYING WITH MOTOROLA'S REQUESTS FOR QUOTATION OR WITH MOTOROLA PURCHASE ORDERS AND SHALL BE RETURNED AT MOTOROLA'S REQUEST. PATENT RIGHTS EMBODIED IN DESIGNS, TOOLS, PATTERNS, DRAWINGS, DEVICES, INFORMATION AND EQUIPMENT SUPPLIED BY MOTOROLA PURSUANT TO THIS REQUEST FOR QUOTATION OR PURCHASE ORDER AND EXCLUSIVE RIGHTS FOR THE USE IN REPRODUCTION THEREOF ARE RESERVED BY MOTOROLA." APPLIED FINISH BLACK OXIDE PER 2. FRACTIONAL 3. DEC. TOL 1/64 FOR 2 STRIP 40 CAVITY MOLD MIL-C-13924B CLASS II t.005 REQ'D USED ON REQ'D USED ON 4. ANGULAR TOL. t MOTOROLA INC. 5. FEATURE CONTROL SYMBOLS PER MIL-STD-8 CURRENT REV. Semiconductor Product Division 1 / 1 180A 5005 EAST MCDOWELL ROAD, PHOENIX, ARIZONA 85008 DRAWN BY L. RICHARDSON 6. BREAK ALL SHARP EDGES & CORNERS, REMOVE BURRS. DATE 4-15 SCALE DWG. NO. 7. UNDERLINED DIMS NOT TO SCALE 1/01 180A-19 CHECKED BY APPROVED BY FULL L. RICHARDSON 9-9

Print Reading for Industry 250 Class Date Name Industry Print Exercise 12-1 Refer to the print PR 12-1 and answer the questions below. 1. How many surface texture symbols are there on the views of this drawing? 2. The two face surfaces perpendicular to the axis of this part that have surface texture specification microinches or smoother. should have a surface texture of 3. For the surface texture symbols that have a horizontal bar, what does the .05 indicate? on the two flat surfaces be in 4. According to the lay symbols shown in the round view, should the lay the same direction as the axis of the cylinder or perpendicular to the axis? 5. What surface texture value should be applied to all surfaces not specified on the drawing views? Review questions based on previous units: 6. What scale are the views on the original drawing for this print? 7. For the fractional dimensions, what tolerances should be applied? 8. What is the part name? 9. Are there any section lines on this drawing? 10. What type of section view is used in this drawing? 11. What is the pitch of the external thread? 12. How are the threads represented? 13. Why is the countersink hole on the right end not dimensioned? 14. There is a limit-method dimension labeled P.D. What does P.D. stand for? 15. What is the MMC of the counterbore diameter? Inc. DWG. NO. 11180A-19 1100 12 oe & al ectT Print supplied by Motorola, In PR 12-1. Ram Adapter. E.C.O. ENG'R LET. CHANGE BY DATE L.F.R. RELEASED RICHARDSON4/15 .001 A 32 3 16 -SMALL NECK 32 -CENTER PERMISSIBLE .05 T 0+ -1/16 +.0005 D.7501-0000 1: 116 ACROSS FLATS + 왕이 16.05 A 12-12 UNF-2A THREAD P.D. 1.0691 1.0631 -13 UNC-2B TO DEPTH SHOWN - O.002 A MATERIAL SPEC. NO. ITEM MATERIAL SPECIFICATION LIST REQ'D CARPENTER 610 UNLESS OTHERWISE SPECIFIED TITLE HEAT TREAT RMS ALL MACHINED SURFACES HARDEN& DRAW R/C 58-60 63 RAM ADAPTER 1. "ANY SPECIFICATIONS, DRAWINGS OR REPRINTS, OR DATA FURNISHED TO BIDDER OR SELLER SHALL REMAIN MOTOROLA'S PROPERTY, SHALL BE KEPT CONFIDENTIAL, SHALL BE USED FOR THE PURPOSE OF COMPLYING WITH MOTOROLA'S REQUESTS FOR QUOTATION OR WITH MOTOROLA PURCHASE ORDERS AND SHALL BE RETURNED AT MOTOROLA'S REQUEST. PATENT RIGHTS EMBODIED IN DESIGNS, TOOLS, PATTERNS, DRAWINGS, DEVICES, INFORMATION AND EQUIPMENT SUPPLIED BY MOTOROLA PURSUANT TO THIS REQUEST FOR QUOTATION OR PURCHASE ORDER AND EXCLUSIVE RIGHTS FOR THE USE IN REPRODUCTION THEREOF ARE RESERVED BY MOTOROLA." APPLIED FINISH BLACK OXIDE PER 2. FRACTIONAL 3. DEC. TOL 1/64 FOR 2 STRIP 40 CAVITY MOLD MIL-C-13924B CLASS II t.005 REQ'D USED ON REQ'D USED ON 4. ANGULAR TOL. t MOTOROLA INC. 5. FEATURE CONTROL SYMBOLS PER MIL-STD-8 CURRENT REV. Semiconductor Product Division 1 / 1 180A 5005 EAST MCDOWELL ROAD, PHOENIX, ARIZONA 85008 DRAWN BY L. RICHARDSON 6. BREAK ALL SHARP EDGES & CORNERS, REMOVE BURRS. DATE 4-15 SCALE DWG. NO. 7. UNDERLINED DIMS NOT TO SCALE 1/01 180A-19 CHECKED BY APPROVED BY FULL L. RICHARDSON 9-9

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

I need help solving problems 4, 5, and 6 pertaining to the print attached below

Transcribed Image Text:Print Reading for Industry

250

Class

Date

Name

Industry Print Exercise 12-1

Refer to the print PR 12-1 and answer the questions below.

1. How many surface texture symbols are there on the views of this drawing?

2. The two face surfaces perpendicular to the axis of this part that have surface texture specification

microinches or smoother.

should have a surface texture of

3. For the surface texture symbols that have a horizontal bar, what does the .05 indicate?

on the two flat surfaces be in

4. According to the lay symbols shown in the round view, should the lay

the same direction as the axis of the cylinder or perpendicular to the axis?

5. What surface texture value should be applied to all surfaces not specified on the drawing views?

Review questions based on previous units:

6. What scale are the views on the original drawing for this print?

7. For the fractional dimensions, what tolerances should be applied?

8. What is the part name?

9. Are there any section lines on this drawing?

10. What type of section view is used in this drawing?

11. What is the pitch of the external thread?

12. How are the threads represented?

13. Why is the countersink hole on the right end not dimensioned?

14. There is a limit-method dimension labeled P.D. What does P.D. stand for?

15. What is the MMC of the counterbore diameter?

Inc.

Transcribed Image Text:DWG. NO.

11180A-19

1100

12

oe & al ectT

Print supplied by Motorola, In

PR 12-1. Ram Adapter.

E.C.O.

ENG'R

LET.

CHANGE

BY

DATE

L.F.R.

RELEASED

RICHARDSON4/15

.001 A

32

3

16

-SMALL NECK

32

-CENTER PERMISSIBLE

.05

T

0+

-1/16

+.0005

D.7501-0000

1:

116

ACROSS FLATS

+

왕이

16.05

A

12-12 UNF-2A THREAD

P.D. 1.0691

1.0631

-13 UNC-2B

TO DEPTH SHOWN -

O.002 A

MATERIAL SPEC.

NO.

ITEM

MATERIAL SPECIFICATION LIST

REQ'D

CARPENTER 610

UNLESS OTHERWISE SPECIFIED TITLE

HEAT TREAT

RMS

ALL MACHINED

SURFACES

HARDEN& DRAW R/C 58-60

63

RAM ADAPTER

1.

"ANY SPECIFICATIONS, DRAWINGS OR REPRINTS,

OR DATA FURNISHED TO BIDDER OR SELLER

SHALL REMAIN MOTOROLA'S PROPERTY, SHALL BE

KEPT CONFIDENTIAL, SHALL BE USED FOR THE

PURPOSE OF COMPLYING WITH MOTOROLA'S

REQUESTS FOR QUOTATION OR WITH MOTOROLA

PURCHASE ORDERS AND SHALL BE RETURNED AT

MOTOROLA'S REQUEST. PATENT RIGHTS

EMBODIED IN DESIGNS, TOOLS, PATTERNS,

DRAWINGS, DEVICES, INFORMATION AND

EQUIPMENT SUPPLIED BY MOTOROLA PURSUANT

TO THIS REQUEST FOR QUOTATION OR PURCHASE

ORDER AND EXCLUSIVE RIGHTS FOR THE USE IN

REPRODUCTION THEREOF ARE RESERVED BY

MOTOROLA."

APPLIED FINISH

BLACK OXIDE PER

2. FRACTIONAL

3. DEC. TOL

1/64

FOR 2 STRIP 40 CAVITY MOLD

MIL-C-13924B CLASS II

t.005

REQ'D USED ON

REQ'D USED ON

4. ANGULAR TOL. t

MOTOROLA INC.

5. FEATURE CONTROL SYMBOLS

PER MIL-STD-8

CURRENT REV.

Semiconductor Product Division

1 / 1 180A

5005 EAST MCDOWELL ROAD, PHOENIX, ARIZONA 85008

DRAWN BY

L. RICHARDSON

6. BREAK ALL SHARP EDGES &

CORNERS, REMOVE BURRS.

DATE

4-15

SCALE

DWG. NO.

7. UNDERLINED DIMS NOT TO

SCALE

1/01 180A-19

CHECKED BY

APPROVED BY

FULL

L. RICHARDSON

9-9

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY