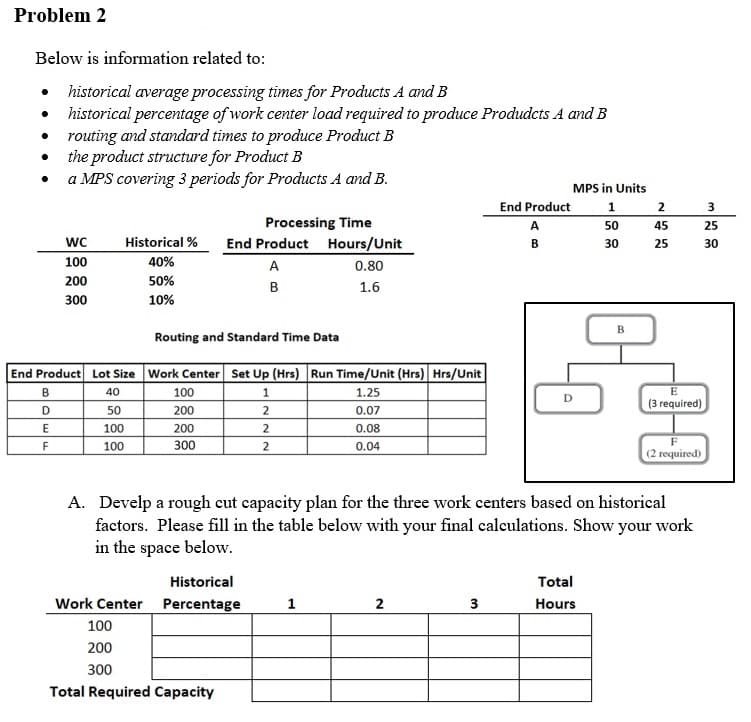

Problem 2 Below is information related to: historical average processing times for Products A and B historical percentage of work center load required to produce Produdcts A and B routing and standard times to produce Product B the product structure for Product B a MPS covering 3 periods for Products A and B. MPS in Units End Product 2 3 Processing Time End Product Hours/Unit A 50 45 25 wc Historical % B. 30 25 30 100 40% A 0.80 200 50% B 1.6 300 10% B Routing and Standard Time Data End Product Lot Size Work Center Set Up (Hrs) Run Time/Unit (Hrs)| Hrs/Unit 40 100 1 1.25 E D (3 required) D 50 200 0.07 E 100 200 2 0.08 F 100 300 2 0.04 (2 required) A. Develp a rough cut capacity plan for the three work centers based on historical factors. Please fill in the table below with your final calculations. Show your work in the space below. Historical Total Work Center Percentage 1 3 Hours 100 200 300 Total Required Capacity

Problem 2 Below is information related to: historical average processing times for Products A and B historical percentage of work center load required to produce Produdcts A and B routing and standard times to produce Product B the product structure for Product B a MPS covering 3 periods for Products A and B. MPS in Units End Product 2 3 Processing Time End Product Hours/Unit A 50 45 25 wc Historical % B. 30 25 30 100 40% A 0.80 200 50% B 1.6 300 10% B Routing and Standard Time Data End Product Lot Size Work Center Set Up (Hrs) Run Time/Unit (Hrs)| Hrs/Unit 40 100 1 1.25 E D (3 required) D 50 200 0.07 E 100 200 2 0.08 F 100 300 2 0.04 (2 required) A. Develp a rough cut capacity plan for the three work centers based on historical factors. Please fill in the table below with your final calculations. Show your work in the space below. Historical Total Work Center Percentage 1 3 Hours 100 200 300 Total Required Capacity

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter4: Linear Programming Models

Section: Chapter Questions

Problem 111P

Related questions

Question

Transcribed Image Text:Problem 2

Below is information related to:

historical average processing times for Products A and B

historical percentage of work center load required to produce Produdcts A and B

routing and standard times to produce Product B

the product structure for Product B

a MPS covering 3 periods for Products A and B.

MPS in Units

End Product

2

3

Processing Time

End Product Hours/Unit

A

50

45

25

wc

Historical %

B.

30

25

30

100

40%

A

0.80

200

50%

B

1.6

300

10%

B

Routing and Standard Time Data

End Product Lot Size Work Center Set Up (Hrs) Run Time/Unit (Hrs)| Hrs/Unit

40

100

1

1.25

E

D

(3 required)

D

50

200

0.07

E

100

200

2

0.08

F

100

300

2

0.04

(2 required)

A. Develp a rough cut capacity plan for the three work centers based on historical

factors. Please fill in the table below with your final calculations. Show your work

in the space below.

Historical

Total

Work Center Percentage

1

3

Hours

100

200

300

Total Required Capacity

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 3 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,