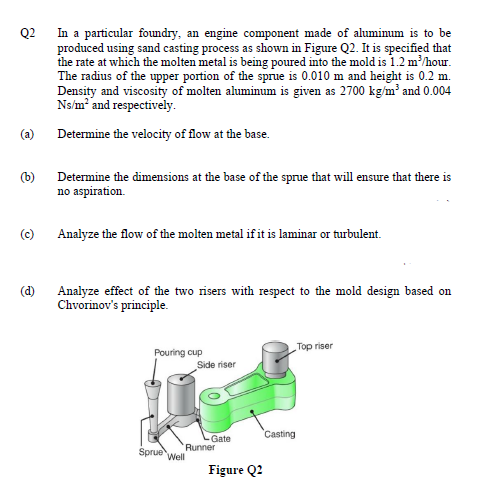

Q2 In a particular foundry, an engine component made of alumimum is to be produced using sand casting process as shown in Figure Q2. It is specified that the rate at which the molten metal is being poured into the mold is 1.2 m³/hour. The radius of the upper portion of the sprue is 0.010 m and height is 0.2 m. Density and viscosity of molten aluminum is given as 2700 kg/m² and 0.004 Ns/m² and respectively. (a) Determine the velocity of flow at the base. (b) Determine the dimensions at the base of the sprue that will ensure that there is no aspiration. (c) Analyze the flow of the molten metal if it is laminar or turbulent.

Q2 In a particular foundry, an engine component made of alumimum is to be produced using sand casting process as shown in Figure Q2. It is specified that the rate at which the molten metal is being poured into the mold is 1.2 m³/hour. The radius of the upper portion of the sprue is 0.010 m and height is 0.2 m. Density and viscosity of molten aluminum is given as 2700 kg/m² and 0.004 Ns/m² and respectively. (a) Determine the velocity of flow at the base. (b) Determine the dimensions at the base of the sprue that will ensure that there is no aspiration. (c) Analyze the flow of the molten metal if it is laminar or turbulent.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter8: Natural Convection

Section: Chapter Questions

Problem 8.28P

Related questions

Question

100%

Transcribed Image Text:In a particular foundry, an engine component made of alumimum is to be

produced using sand casting process as shown in Figure Q2. It is specified that

the rate at which the molten metal is being poured into the mold is 1.2 m³/hour.

The radius of the upper portion of the sprue is 0.010 m and height is 0.2 m.

Density and viscosity of molten aluminum is given as 2700 kg/m? and 0.004

Ns/m² and respectively.

Q2

(a)

Determine the velocity of flow at the base.

(b)

Determine the dimensions at the base of the sprue that will ensure that there is

no aspiration.

(c)

Analyze the flow of the molten metal if it is laminar or turbulent.

(d)

Analyze effect of the two risers with respect to the mold design based on

Chvorinov's principle.

Top riser

Pouring cup

Side riser

Casting

Gate

Runner

Sprue Well

Figure Q2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning