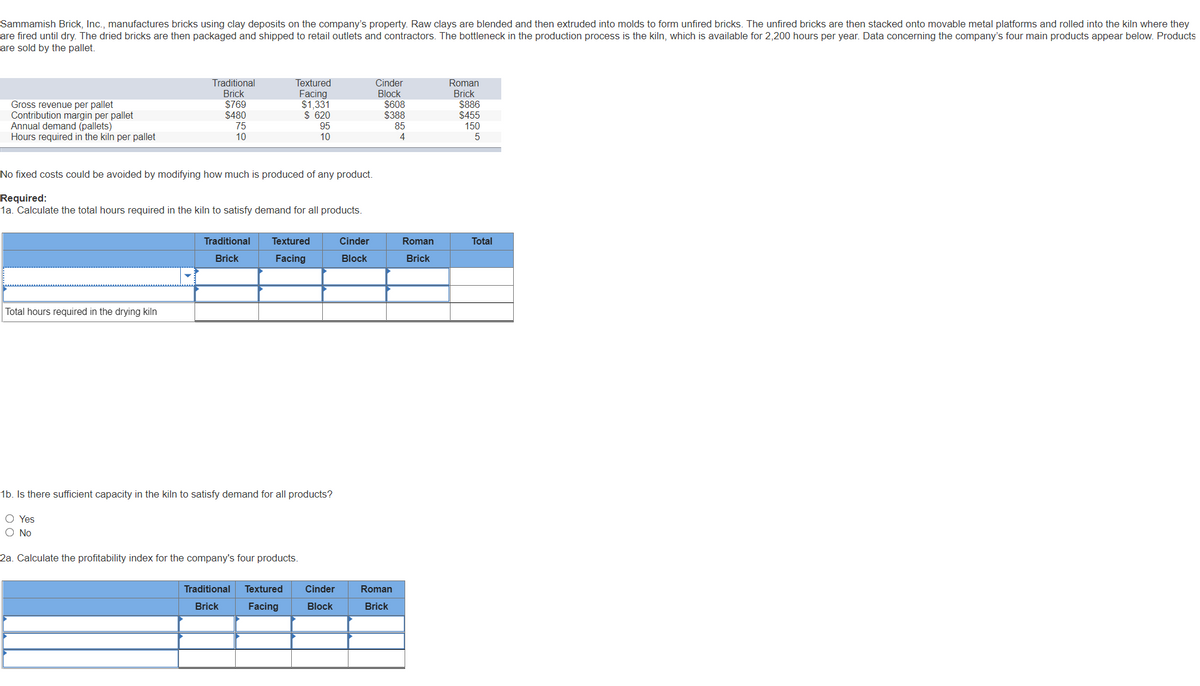

Sammamish Brick, Inc., manufactures bricks using clay deposits on the company's property. Raw clays are blended and then extruded into molds to form unfired bricks. The unfired bricks are then stacked onto movable metal platforms and rolled into the kiln where they are fired until dry. The dried bricks are then packaged and shipped to retail outlets and contractors. The bottleneck in the production process is the kiln, which is available for 2,200 hours per year. Data concerning the company's four main products appear below. Products are sold by the pallet. Gross revenue per pallet Contribution margin per pallet Annual demand (pallets) Hours required in the kiln per pallet Traditional Brick $769 $480 75 10 Textured Facing $1,331 $ 620 95 10 Cinder Block $608 $388 85 4 Roman Brick $886 $455 150 No fixed costs could be avoided by modifying how much is produced of any product. Required: la. Calculate the total hours required in the kiln to satisfy demand for all products. Traditional Textured Cinder Roman Total Brick Facing Block Brick Total hours required in the drying kiln 1b. Is there sufficient capacity in the kiln to satisfy demand for all products? O Yes O No 2a. Calculate the profitability index for the company's four products. . Traditional Textured Cinder Roman Brick Facing Block Brick

Sammamish Brick, Inc., manufactures bricks using clay deposits on the company's property. Raw clays are blended and then extruded into molds to form unfired bricks. The unfired bricks are then stacked onto movable metal platforms and rolled into the kiln where they are fired until dry. The dried bricks are then packaged and shipped to retail outlets and contractors. The bottleneck in the production process is the kiln, which is available for 2,200 hours per year. Data concerning the company's four main products appear below. Products are sold by the pallet. Gross revenue per pallet Contribution margin per pallet Annual demand (pallets) Hours required in the kiln per pallet Traditional Brick $769 $480 75 10 Textured Facing $1,331 $ 620 95 10 Cinder Block $608 $388 85 4 Roman Brick $886 $455 150 No fixed costs could be avoided by modifying how much is produced of any product. Required: la. Calculate the total hours required in the kiln to satisfy demand for all products. Traditional Textured Cinder Roman Total Brick Facing Block Brick Total hours required in the drying kiln 1b. Is there sufficient capacity in the kiln to satisfy demand for all products? O Yes O No 2a. Calculate the profitability index for the company's four products. . Traditional Textured Cinder Roman Brick Facing Block Brick

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter6: Process Costing

Section: Chapter Questions

Problem 38P: Healthway uses a process-costing system to compute the unit costs of the minerals that it produces....

Related questions

Question

Transcribed Image Text:Sammamish Brick, Inc., manufactures bricks using clay deposits on the company's property. Raw clays are blended and then extruded into molds to form unfired bricks. The unfired bricks are then stacked onto movable metal platforms and rolled into the kiln where they

are fired until dry. The dried bricks are then packaged and shipped to retail outlets and contractors. The bottleneck in the production process is the kiln, which is available for 2,200 hours per year. Data concerning the company's four main products appear below. Products

are sold by the pallet.

Gross revenue per pallet

Contribution margin per pallet

Annual demand (pallets)

Hours required in the kiln per pallet

Traditional

Brick

$769

$480

75

10

Textured

Facing

$1,331

$ 620

Cinder

Block

$608

$388

85

4

Roman

Brick

$886

$455

95

10

150

No fixed costs could be avoided by modifying how much is produced of any product.

Required:

1a. Calculate the total hours required in the kiln to satisfy demand for all products.

Traditional

Textured

Cinder

Roman

Total

Brick

Facing

Block

Brick

Total hours required in the drying kiln

1b. Is there sufficient capacity in the kiln to satisfy demand for all products?

O Yes

O No

2a. Calculate the profitability index for the company's four products.

Traditional

Textured

Cinder

Roman

Brick

Facing

Block

Brick

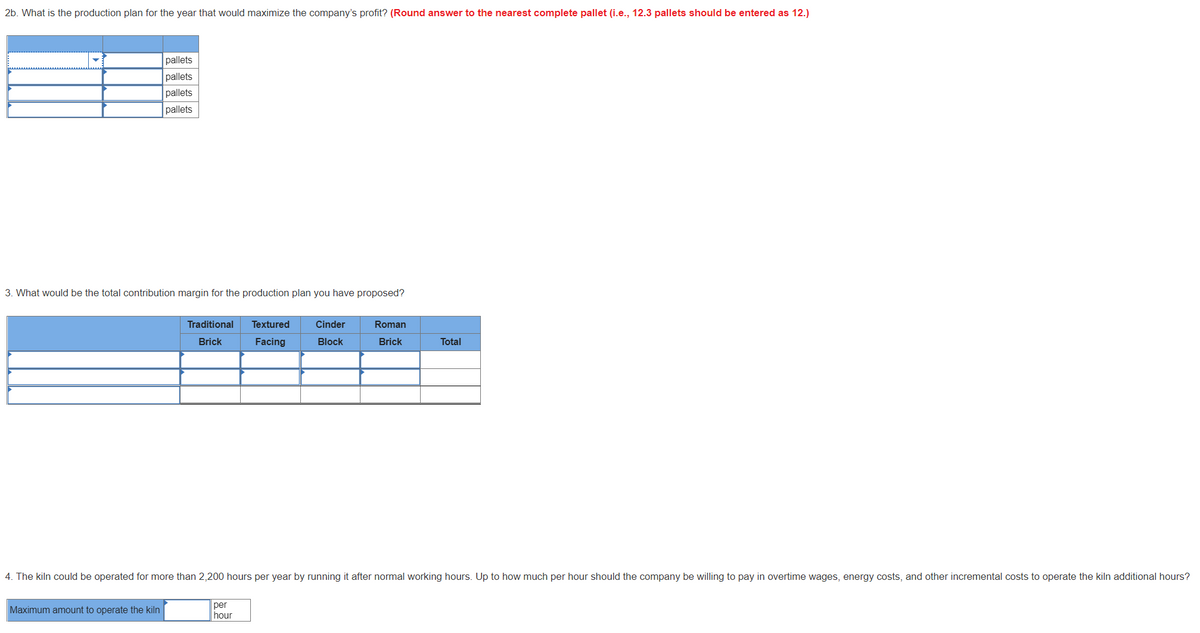

Transcribed Image Text:2b. What is the production plan for the year that would maximize the company's profit? (Round answer to the nearest complete pallet (i.e., 12.3 pallets should be entered as 12.)

pallets

pallets

pallets

pallets

3. What would be the total contribution margin for the production plan you have proposed?

Traditional

Textured

Cinder

Roman

Brick

Facing

Block

Brick

Total

4. The kiln could be operated for more than 2,200 hours per year by running it after normal working hours. Up to how much per hour should the company be willing to pay in overtime wages, energy costs, and other incremental costs to operate the kiln additional hours?

Maximum amount to operate the kiln

per

hour

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning