SureRock Inc. manufactures curling rocks which are used worldwide in curling rinks and for bonspiels and tournaments. SureRock has a single production department, the Assembly department, which is highly automated to ensure that the curling rocks are of consistent quality. Production begins by the introduction of all the raw materials (granite, electronic sensors, plastics, and adhesives) that are added at the beginning of the process and ends when the completed rock is polished and loaded into individual crates. The rocks are then transferred to the shipping department. Direct labour and manufacturing overhead are added continuously throughout the process. “ Prior to October, when a change in the manufacturing process was implements, production increased significantly. One of the polishing machines was incorrectly calibrated, and it was found that some of the curling rocks incurred small cracks in the granite as a result. Normally, SureRock allows for 2% of good rocks produced. e The data related to the actual production for the month of October is: Costse Work-in-process inventory, October 1e Direct materialse Conversion costse Costs added in month of Maye Direct materialse Direct labour Manufacturing overhead $ 38,400e 33,600 de 371,200 97,440e 227,360e Work-in-process inventory, October 1 (30% completed) Units started in Octobere Units completed and transferred to shipping Work-in-process inventory, October 31 (80% completed)- Unitsde 300e 2,900e 2,500e 550e Required: Prepare a production cost report for October using the weighted-average method.e

SureRock Inc. manufactures curling rocks which are used worldwide in curling rinks and for bonspiels and tournaments. SureRock has a single production department, the Assembly department, which is highly automated to ensure that the curling rocks are of consistent quality. Production begins by the introduction of all the raw materials (granite, electronic sensors, plastics, and adhesives) that are added at the beginning of the process and ends when the completed rock is polished and loaded into individual crates. The rocks are then transferred to the shipping department. Direct labour and manufacturing overhead are added continuously throughout the process. “ Prior to October, when a change in the manufacturing process was implements, production increased significantly. One of the polishing machines was incorrectly calibrated, and it was found that some of the curling rocks incurred small cracks in the granite as a result. Normally, SureRock allows for 2% of good rocks produced. e The data related to the actual production for the month of October is: Costse Work-in-process inventory, October 1e Direct materialse Conversion costse Costs added in month of Maye Direct materialse Direct labour Manufacturing overhead $ 38,400e 33,600 de 371,200 97,440e 227,360e Work-in-process inventory, October 1 (30% completed) Units started in Octobere Units completed and transferred to shipping Work-in-process inventory, October 31 (80% completed)- Unitsde 300e 2,900e 2,500e 550e Required: Prepare a production cost report for October using the weighted-average method.e

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter4: Activity-based Costing

Section: Chapter Questions

Problem 36P: Reducir, Inc., produces two different types of hydraulic cylinders. Reducir produces a major...

Related questions

Question

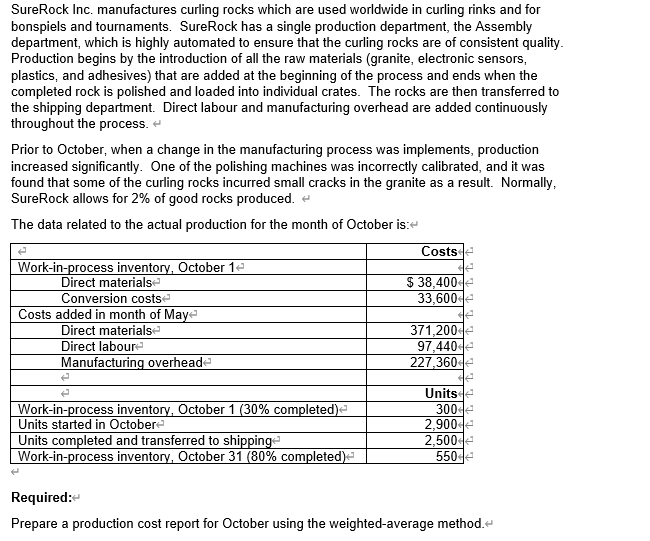

Transcribed Image Text:SureRock Inc. manufactures curling rocks which are used worldwide in curling rinks and for

bonspiels and tournaments. SureRock has a single production department, the Assembly

department, which is highly automated to ensure that the curling rocks are of consistent quality.

Production begins by the introduction of all the raw materials (granite, electronic sensors,

plastics, and adhesives) that are added at the beginning of the process and ends when the

completed rock is polished and loaded into individual crates. The rocks are then transferred to

the shipping department. Direct labour and manufacturing overhead are added continuously

throughout the process. e

Prior to October, when a change in the manufacturing process was implements, production

increased significantly. One of the polishing machines was incorrectly calibrated, and it was

found that some of the curling rocks incurred small cracks in the granite as a result. Normally,

SureRock allows for 2% of good rocks produced. e

The data related to the actual production for the month of October is:e

Costse

Work-in-process inventory, October 1e

Direct materialse

$ 38,400e

33,600e

Conversion costse

Costs added in month of Maye

Direct materialse

Direct laboure

Manufacturing overheade

371,2004e

97,440

227,360e

Work-in-process inventory, October 1 (30% completed)e

Units started in Octobere

Units completed and transferred to shippinge

Work-in-process inventory, October 31 (80% completed)=

Unitse

300e

2,9004

2,5004e

550e

Required:

Prepare a production cost report for October using the weighted-average method.e

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub