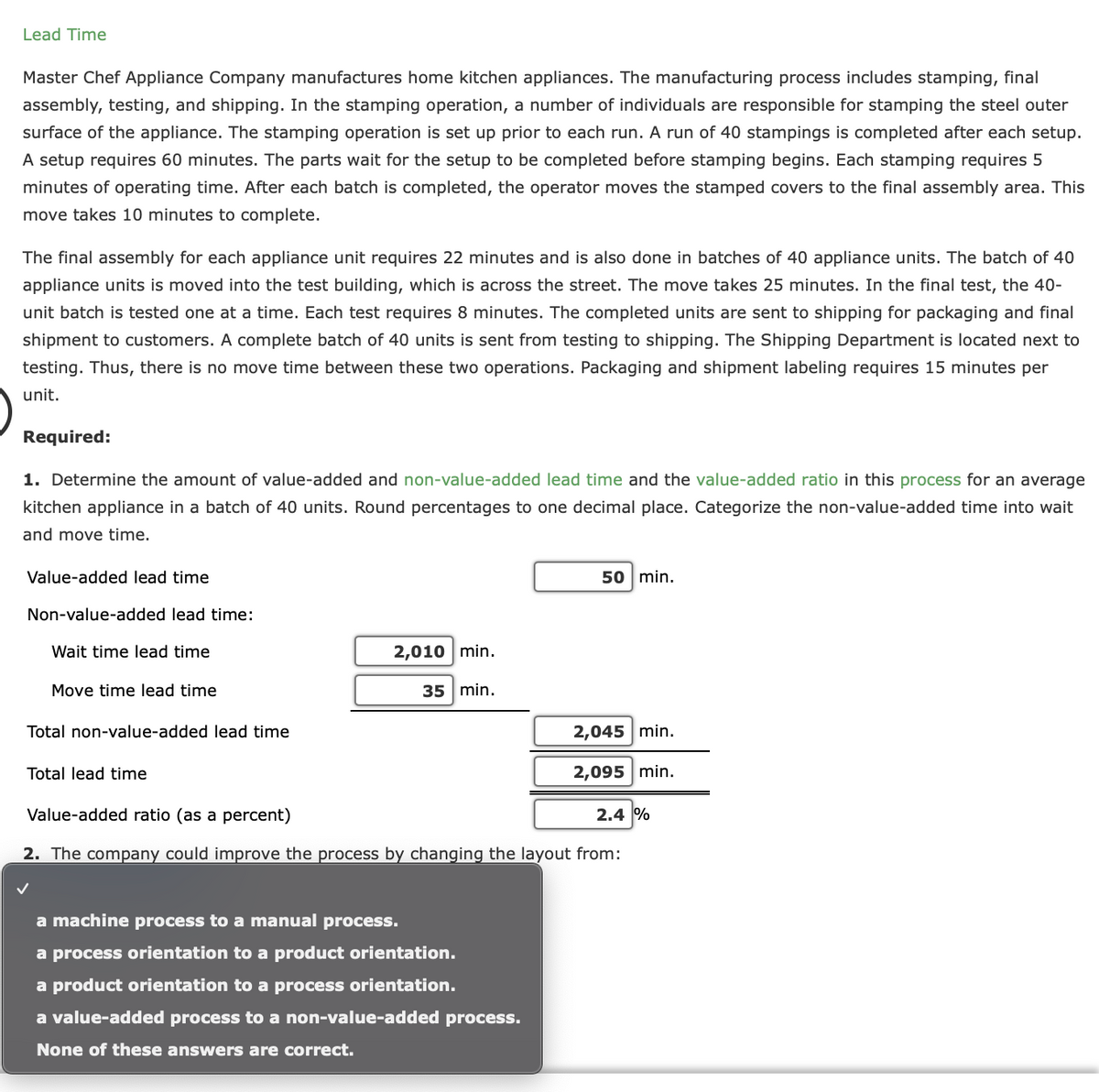

Master Chef Appliance Company manufactures home kitchen appliances. The manufacturing process includes stamping, final assembly, testing, and shipping. In the stamping operation, a number of individuals are responsible for stamping the steel outer surface of the appliance. The stamping operation is set up prior to each run. A run of 40 stampings is completed after each setup. A setup requires 60 minutes. The parts wait for the setup to be completed before stamping begins. Each stamping requires 5 minutes of operating time. After each batch is completed, the operator moves the stamped covers to the final assembly area. This move takes 10 minutes to complete. The final assembly for each appliance unit requires 22 minutes and is also done in batches of 40 appliance units. The batch of 40 appliance units is moved into the test building, which is across the street. The move takes 25 minutes. In the final test, the 40- unit batch is tested one at a time. Each test requires 8 minutes. The completed units are sent to shipping for packaging and final shipment to customers. A complete batch of 40 units is sent from testing to shipping. The Shipping Department is located next to testing. Thus, there is no move time between these two operations. Packaging and shipment labeling requires 15 minutes per unit. Required: 1. Determine the amount of value-added and non-value-added lead time and the value-added ratio in this process for an average kitchen appliance in a batch of 40 units. Round percentages to one decimal place. Categorize the non-value-added time into wait and move time. Value-added lead time 50 min. Non-value-added lead time: Wait time lead time 2,010 min. Move time lead time 35 min. Total non-value-added lead time 2,045 min. Total lead time 2,095 min. Value-added ratio (as a percent) 2.4 % 2. The company could improve the process by changing the layout from: a machine process to a manual process. a process orientation to a product orientation. a product orientation to a process orientation. a value-added process to a non-value-added process. None of these answers are correct.

Process Costing

Process costing is a sort of operation costing which is employed to determine the value of a product at each process or stage of producing process, applicable where goods produced from a series of continuous operations or procedure.

Job Costing

Job costing is adhesive costs of each and every job involved in the production processes. It is an accounting measure. It is a method which determines the cost of specific jobs, which are performed according to the consumer’s specifications. Job costing is possible only in businesses where the production is done as per the customer’s requirement. For example, some customers order to manufacture furniture as per their needs.

ABC Costing

Cost Accounting is a form of managerial accounting that helps the company in assessing the total variable cost so as to compute the cost of production. Cost accounting is generally used by the management so as to ensure better decision-making. In comparison to financial accounting, cost accounting has to follow a set standard ad can be used flexibly by the management as per their needs. The types of Cost Accounting include – Lean Accounting, Standard Costing, Marginal Costing and Activity Based Costing.

I just need help with question 2 (the multiple choice one)

thank you

Trending now

This is a popular solution!

Step by step

Solved in 3 steps