The current manufacturing process layout is shown below. Area A Area C Area D Entrance Receiving (2) Area B Area E Parts (3) Breakdown Assembly Inspection Test 10m (5) (6) (2) (8) Area F Area G Cece Racing Metallurgy 10m (4) The number of material movements between the 8 departments per month is shown in the following table: Department O Area H 100 100 Entrance (1) 050 Receiving (2) 30 30000 Parts (3) 2020 Metallurgy (4) 2010 Breakdown (5) 30 Assembly (6) 200 0 O 0 Inspection (7) Re-arrange the layout to minimise the total movement (distance travelled in metres) of material. Adjacent departments (including diagonal) are 10 m apart, non-adjacent departments are 20 or 30 m apart, depending on location. The entrance must remain in its current location. The objective is: Minimise material movement - ΣEXC here X, number of material movements per month Σας, AA (loads or trips) moving from department / to

The current manufacturing process layout is shown below. Area A Area C Area D Entrance Receiving (2) Area B Area E Parts (3) Breakdown Assembly Inspection Test 10m (5) (6) (2) (8) Area F Area G Cece Racing Metallurgy 10m (4) The number of material movements between the 8 departments per month is shown in the following table: Department O Area H 100 100 Entrance (1) 050 Receiving (2) 30 30000 Parts (3) 2020 Metallurgy (4) 2010 Breakdown (5) 30 Assembly (6) 200 0 O 0 Inspection (7) Re-arrange the layout to minimise the total movement (distance travelled in metres) of material. Adjacent departments (including diagonal) are 10 m apart, non-adjacent departments are 20 or 30 m apart, depending on location. The entrance must remain in its current location. The objective is: Minimise material movement - ΣEXC here X, number of material movements per month Σας, AA (loads or trips) moving from department / to

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Transcribed Image Text:Question 1.

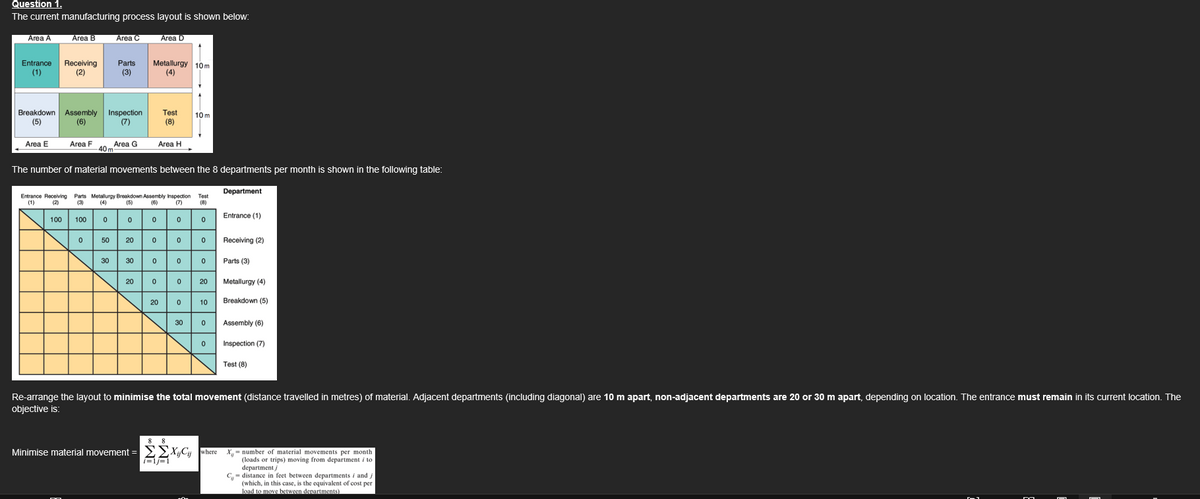

The current manufacturing process layout is shown below:

Area A

Entrance

(1)

Area B

Area E

Receiving

(2)

Breakdown Assembly

(5)

(6)

Area F

0

Area C

Inspection

(7)

40m

Parts

(3)

Area G

30

The number of material movements between the 8 departments per month is shown in the following table:

50 20 0

Metallurgy 10m

(4)

Entrance Receiving Parts Metallurgy Breakdown Assembly Inspection Test

(2) (3)

(5) (6) (7)

(1)

(8)

100 100。。。。。

30

20

Area D

0

0

Test 10m

(8)

Area H

20

0

0

0

0

30

0

0

20

10

0

0

Department

Entrance (1)

Minimise material movement = XCywhere

Receiving (2)

Parts (3)

Metallurgy (4)

Breakdown (5)

Assembly (6)

Inspection (7)

Test (8)

Re-arrange the layout to minimise the total movement (distance travelled in metres) of material. Adjacent departments (including diagonal) are 10 m apart, non-adjacent departments are 20 or 30 m apart, depending on location. The entrance must remain in its current location. The

objective is:

8 8

ΣXjCij where X = number of material movements per month

(loads or trips) moving from department i to

department/

Cdistance in feet between departments i and

(which, in this case, is the equivalent of cost per

load to move between departments)

3

E

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 7 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.