The CyClon project team has started gathering the information necessary to develop a project network-predecessor activities and activity time in days. The results of their meeting are found in the following table: Duration Predecessor 11 Activity Description A Design Procure prototype parts Fabricate parts Assemble prototype

The CyClon project team has started gathering the information necessary to develop a project network-predecessor activities and activity time in days. The results of their meeting are found in the following table: Duration Predecessor 11 Activity Description A Design Procure prototype parts Fabricate parts Assemble prototype

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

Transcribed Image Text:EX 6-23 (Algo) The CyClon project team has started...

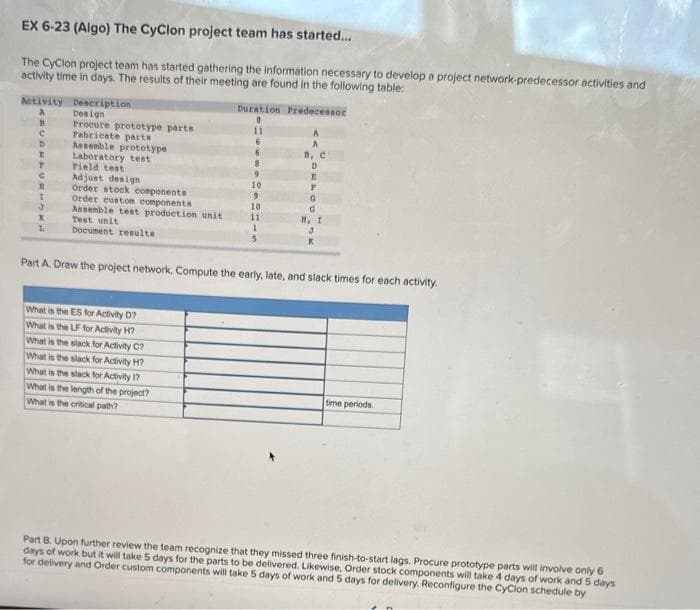

The Cyclon project team has started gathering the information necessary to develop a project network-predecessor activities and

activity time in days. The results of their meeting are found in the following table:

Activity Description

A

B

C

D

K

Y

G

H

I

J

K

L

Design

Procure prototype parts

Fabricate parts

Assemble prototype

Laboratory test

Pield test

Adjust design

order stock components

Order custom components

Assemble test production unit

Test unit

Document results

Duration Predecessor

11

6

What is the ES for Activity D?

What is the LF for Activity H?

What is the slack for Activity C?

What is the slack for Activity H?

What is the slack for Activity 17

What is the length of the project?

What is the critical path?

8

9

10

9

10

11

A

A

B, C

D

F

G

G

H, I

3

Part A. Draw the project network. Compute the early, late, and slack times for each activity.

time periods

Part B. Upon further review the team recognize that they missed three finish-to-start lags. Procure prototype parts will involve only 6

days of work but it will take 5 days for the parts to be delivered. Likewise, Order stock components will take 4 days of work and 5 days

for delivery and Order custom components will take 5 days of work and 5 days for delivery. Reconfigure the CyClon schedule by

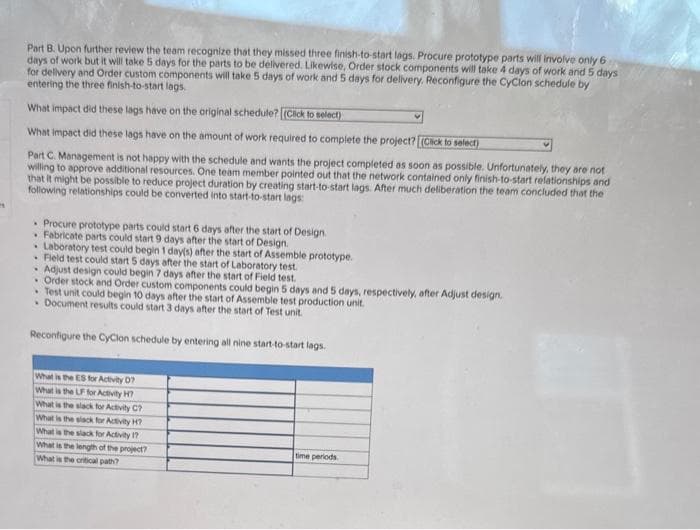

Transcribed Image Text:Part B. Upon further review the team recognize that they missed three finish-to-start lags. Procure prototype parts will involve only 6

days of work but it will take 5 days for the parts to be delivered. Likewise, Order stock components will take 4 days of work and 5 days

for delivery and Order custom components will take 5 days of work and 5 days for delivery. Reconfigure the CyClon schedule by

entering the three finish-to-start lags.

What impact did these lags have on the original schedule? [(Click to select)

What impact did these lags have on the amount of work required to complete the project? [(Click to select)

Part C. Management is not happy with the schedule and wants the project completed as soon as possible. Unfortunately, they are not

willing to approve additional resources. One team member pointed out that the network contained only finish-to-start relationships and

that it might be possible to reduce project duration by creating start-to-start lags. After much deliberation the team concluded that the

following relationships could be converted into start-to-start lags:

. Procure prototype parts could start 6 days after the start of Design.

Fabricate parts could start 9 days after the start of Design.

Laboratory test could begin 1 day(s) after the start of Assemble prototype.

Field test could start 5 days after the start of Laboratory test.

Adjust design could begin 7 days after the start of Field test.

Order stock and Order custom components could begin 5 days and 5 days, respectively, after Adjust design.

Test unit could begin 10 days after the start of Assemble test production unit.

Document results could start 3 days after the start of Test unit.

Reconfigure the Cyclon schedule by entering all nine start-to-start lags.

What is the ES for Activity D?

What is the LF for Activity H?

What is the slack for Activity C?

What is the slack for Activity H?

What is the slack for Activity 1?

What is the length of the project?

What is the critical path?

time periods

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.