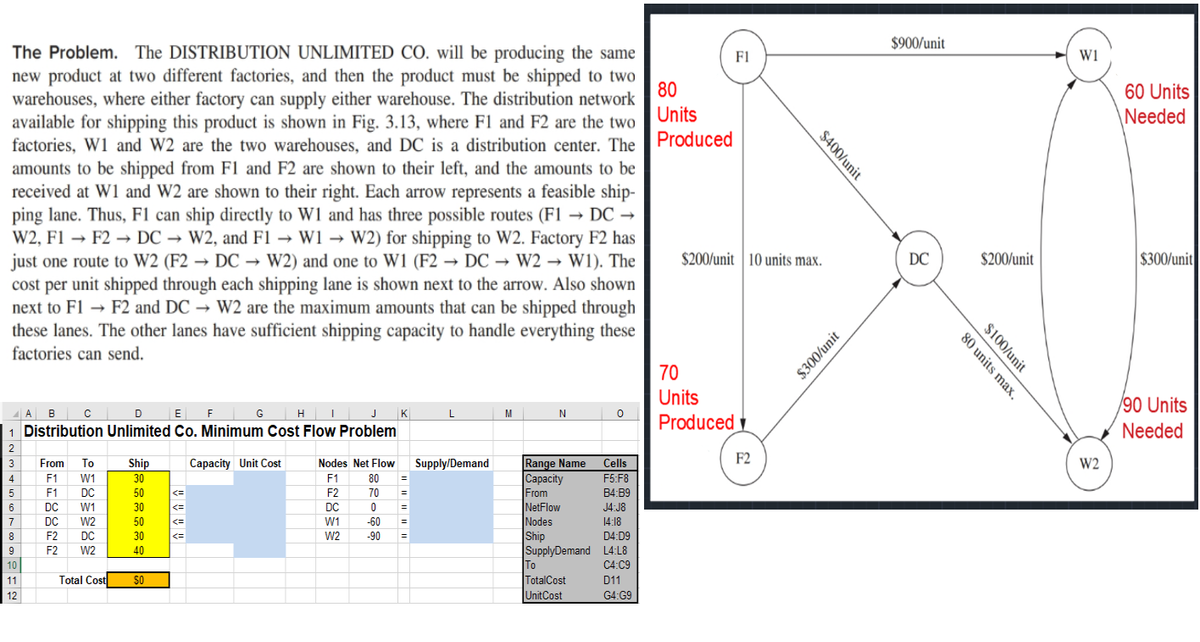

the Problem. The DISTRIBUTION UNLIMITED CO. will be producing the same new product at two different factories, and then the product must be shipped to two warehouses, where either factory can supply either warehouse. The distribution network available for shipping this product is shown in Fig. 3.13, where F1 and F2 are the two factories, W1 and W2 are the two warehouses, and DC is a distribution center. The amounts to be shipped from F1 and F2 are shown to their left, and the amounts to be received at W1 and W2 are shown to their right. Each arrow represents a feasible shipping lane. Thus, F1 can ship directly to W1 and has three possible routes (F1 → DC → W2, F1 → F2 → DC → W2, and F1 → W1 → W2) for shipping to W2. Factory F2 has just one route to W2 (F2 → DC → W2) and one to W1 (F2 → DC → W2 → W1). The cost per unit shipped through each shipping lane is shown next to the arrow. Also shown next to F1 → F2 and DC → W2 are the maximum amounts that can be shipped through these lanes. The other lanes have sufficient shipping capacity to handle everything these factories can send. Included is an Excel sheet to help solve this linear programming problem. The factory units produced and the warehouse needs are expressed in red. Please explain how you arrive at your answer and are able to manipulate the simplex solver to accomplish this task as I am having trouble with it.

the Problem. The DISTRIBUTION UNLIMITED CO. will be producing the same new product at two different factories, and then the product must be shipped to two warehouses, where either factory can supply either warehouse. The distribution network available for shipping this product is shown in Fig. 3.13, where F1 and F2 are the two factories, W1 and W2 are the two warehouses, and DC is a distribution center. The amounts to be shipped from F1 and F2 are shown to their left, and the amounts to be received at W1 and W2 are shown to their right. Each arrow represents a feasible shipping lane. Thus, F1 can ship directly to W1 and has three possible routes (F1 → DC → W2, F1 → F2 → DC → W2, and F1 → W1 → W2) for shipping to W2. Factory F2 has just one route to W2 (F2 → DC → W2) and one to W1 (F2 → DC → W2 → W1). The cost per unit shipped through each shipping lane is shown next to the arrow. Also shown next to F1 → F2 and DC → W2 are the maximum amounts that can be shipped through these lanes. The other lanes have sufficient shipping capacity to handle everything these factories can send.

Included is an Excel sheet to help solve this linear programming problem. The factory units produced and the warehouse needs are expressed in red. Please explain how you arrive at your answer and are able to manipulate the simplex solver to accomplish this task as I am having trouble with it.

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 2 images