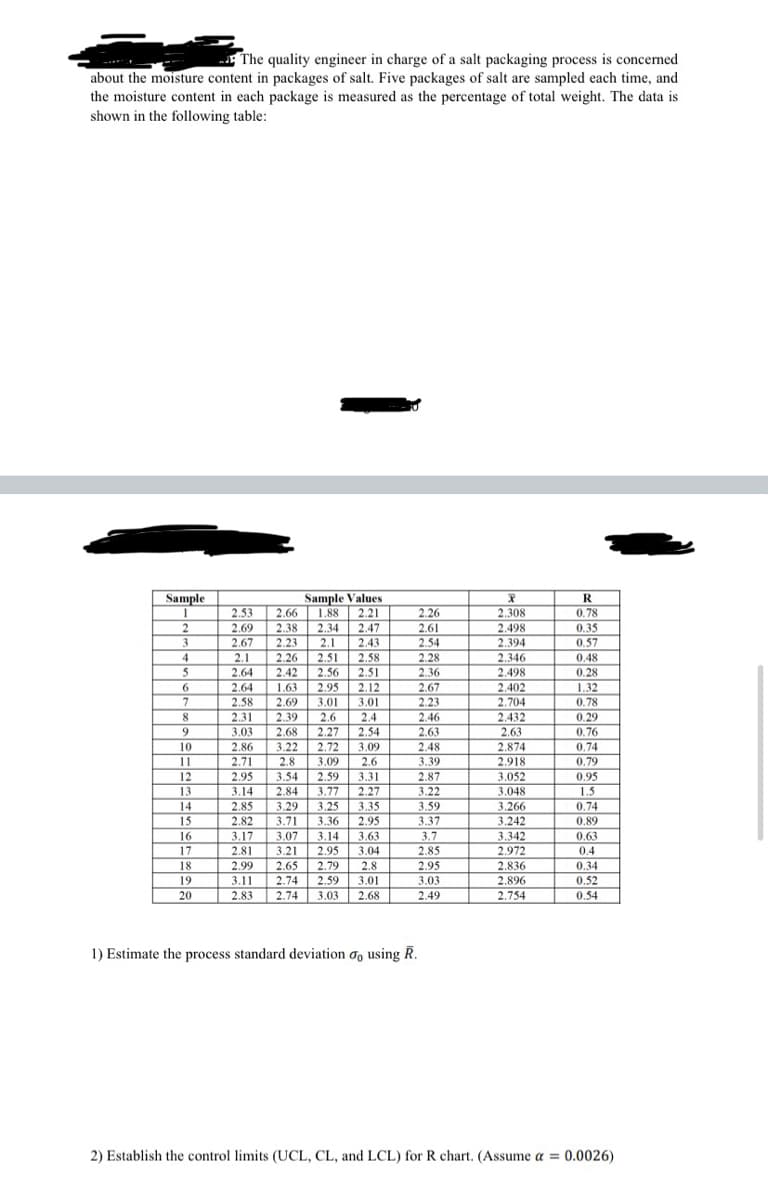

The quality engineer in charge of a salt packaging process is concerned about the moisture content in packages of salt. Five packages of salt are sampled each time, and the moisture content in each package is measured as the percentage of total weight. The data is shown in the following table: Sample Values 2.21 2,47 Sample 2.53 2.66 1.88 2.26 2.308 0.78 0,35 0.57 2.38 2.23 2.26 2.42 1.63 2.69 2.34 2.61 2.498 2.54 2.67 2.1 2.64 2.64 2.1 2.43 2.58 2.394 2.346 2.498 2.402 3. 2.51 2.56 4 2.28 0.48 2.51 0,28 2.36 2.67 2.95 2.12 3.01 6. 1.32 2.58 2.69 3.01 2.23 2.704 0,78 8. 2.31 2.39 2.6 2.27 2.4 2.46 2.432 0.29 2.54 0.76 0,74 0.79 0.95 9. 3.03 2.68 2.63 2.63 10 2.86 3.22 2.72 3.09 2.48 2,874 11 2.71 2.95 3.14 2.8 3.54 3,09 2.6 3.31 2.27 3.35 2.95 3.39 2.918 3.052 12 2.59 3.77 2.87 13 2.84 3.29 3.22 3.59 3,048 1.5 14 15 2.85 3.25 3.266 0.74 3.71 3.07 2.82 3.36 3.37 3.242 0.89 16 3.17 3.14 3,63 3.7 3,342 2.972 0.63 17 2.81 3.21 2.95 3.04 2.85 0.4 18 2.99 2.65 2.79 2.8 2.95 2.836 0.34 3.11 2.83 2.74 2.74 2.59 3.03 2.49 2.896 2.754 19 3.01 0,52 20 3.03 2.68 0,54 1) Estimate the process standard deviation oo using R. 2) Establish the control limits (UCL, CL, and LCL) for R chart. (Assume a = 0.0026)

The quality engineer in charge of a salt packaging process is concerned about the moisture content in packages of salt. Five packages of salt are sampled each time, and the moisture content in each package is measured as the percentage of total weight. The data is shown in the following table: Sample Values 2.21 2,47 Sample 2.53 2.66 1.88 2.26 2.308 0.78 0,35 0.57 2.38 2.23 2.26 2.42 1.63 2.69 2.34 2.61 2.498 2.54 2.67 2.1 2.64 2.64 2.1 2.43 2.58 2.394 2.346 2.498 2.402 3. 2.51 2.56 4 2.28 0.48 2.51 0,28 2.36 2.67 2.95 2.12 3.01 6. 1.32 2.58 2.69 3.01 2.23 2.704 0,78 8. 2.31 2.39 2.6 2.27 2.4 2.46 2.432 0.29 2.54 0.76 0,74 0.79 0.95 9. 3.03 2.68 2.63 2.63 10 2.86 3.22 2.72 3.09 2.48 2,874 11 2.71 2.95 3.14 2.8 3.54 3,09 2.6 3.31 2.27 3.35 2.95 3.39 2.918 3.052 12 2.59 3.77 2.87 13 2.84 3.29 3.22 3.59 3,048 1.5 14 15 2.85 3.25 3.266 0.74 3.71 3.07 2.82 3.36 3.37 3.242 0.89 16 3.17 3.14 3,63 3.7 3,342 2.972 0.63 17 2.81 3.21 2.95 3.04 2.85 0.4 18 2.99 2.65 2.79 2.8 2.95 2.836 0.34 3.11 2.83 2.74 2.74 2.59 3.03 2.49 2.896 2.754 19 3.01 0,52 20 3.03 2.68 0,54 1) Estimate the process standard deviation oo using R. 2) Establish the control limits (UCL, CL, and LCL) for R chart. (Assume a = 0.0026)

Glencoe Algebra 1, Student Edition, 9780079039897, 0079039898, 2018

18th Edition

ISBN:9780079039897

Author:Carter

Publisher:Carter

Chapter10: Statistics

Section10.4: Distributions Of Data

Problem 19PFA

Related questions

Question

4

Please answer all questions thoroughly

Transcribed Image Text:3) Establish the control limits (UCL, CL, and LCL) for X-bar chart. (Assume a = 0.0026)

4) If the specification limits are 2.70 0.15, find the process capability indices Cp and Cpk.

Transcribed Image Text:- The quality engineer in charge of a salt packaging process is concerned

about the moisture content in packages of salt. Five packages of salt are sampled each time, and

the moisture content in each package is measured as the percentage of total weight. The data is

shown in the following table:

Sample

Sample Values

R

2.26

0,78

2.53

2.69

2.66

1,88

2.21

2.308

2.498

0,35

0.57

2

2.38

2.34

2.47

2.61

3

2.67

2.23

2.1

2.43

2.54

2.394

4

2.1

2.26

2.51

2.58

2.28

2.346

0.48

5

2.64

2.42

2.56

2.51

2.36

2.498

0,28

2.67

2.23

2.46

6

1.32

2.64

2.58

2.31

1.63

2.95

2.12

2.402

2.69

2.39

2.68

3.22

3.01

2.4

2.54

2.704

2,432

3.01

0.78

8

2.6

2.27

2,72

0,29

3.03

2.63

2.63

2,874

9

0.76

0.74

0.79

10

2.86

3.09

2.48

11

2.71

2.95

2.8

3.09

2.6

3.39

2.918

3.31

2.27

3.35

12

3.54

2.59

2.87

3.052

0.95

13

3.14

2.84

3.77

3.22

3.048

1.5

2.85

2.82

3.25

3.36

14

3.29

3.59

3.266

0.74

3.242

3,342

15

3.71

3.07

3.21

2.95

3.37

3.7

0.89

16

3.17

3.14

3.63

0.63

17

2.81

2.95

3.04

2.85

2.972

0.4

18

2.99

2.65

2.79

2.8

2.95

2.836

0,34

19

3.11

2.74

2.59

3.01

3.03

2.896

0.52

20

2,83

2.74

3.03

2.68

2.49

2.754

0.54

1) Estimate the process standard deviation o, using R.

2) Establish the control limits (UCL, CL, and LCL) for R chart. (Assume a = 0.0026)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Glencoe Algebra 1, Student Edition, 9780079039897…

Algebra

ISBN:

9780079039897

Author:

Carter

Publisher:

McGraw Hill

Glencoe Algebra 1, Student Edition, 9780079039897…

Algebra

ISBN:

9780079039897

Author:

Carter

Publisher:

McGraw Hill