This exercise only contains parts b, c, d, e, and f. b) Given the demand, the cycle time for the production of the new train set= seconds (round your response to one decimal place). c) The theoretical minimum number of workstations = (round your response up to the next whole number). d) Using the longest operation time rule, the assignment of tasks to workstations should be: (Hint: Number workstations sequentially in terms of precedence relationships and combine any applicable tasks.) Task Workstation # A B Station 2 C D E F Were you able to assign all the tasks to the theoretical minimum number of workstations? e) The total idle time per cycle for the process = seconds (enter your response as a whole number). f) The efficiency of the assembly line with 5 workstations =% (enter your response as a percentage rounded to one decimal place). If one used 6 workstations instead of 5, the efficiency of the assembly line would be =% (enter your response as a percentage rounded to one decimal place).

This exercise only contains parts b, c, d, e, and f. b) Given the demand, the cycle time for the production of the new train set= seconds (round your response to one decimal place). c) The theoretical minimum number of workstations = (round your response up to the next whole number). d) Using the longest operation time rule, the assignment of tasks to workstations should be: (Hint: Number workstations sequentially in terms of precedence relationships and combine any applicable tasks.) Task Workstation # A B Station 2 C D E F Were you able to assign all the tasks to the theoretical minimum number of workstations? e) The total idle time per cycle for the process = seconds (enter your response as a whole number). f) The efficiency of the assembly line with 5 workstations =% (enter your response as a percentage rounded to one decimal place). If one used 6 workstations instead of 5, the efficiency of the assembly line would be =% (enter your response as a percentage rounded to one decimal place).

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter2: Introduction To Spreadsheet Modeling

Section: Chapter Questions

Problem 20P: Julie James is opening a lemonade stand. She believes the fixed cost per week of running the stand...

Related questions

Question

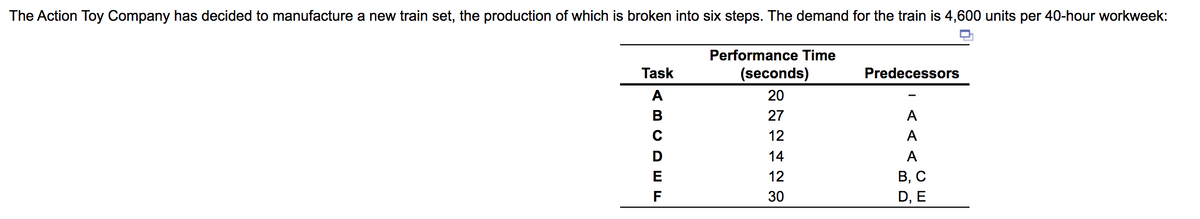

Transcribed Image Text:The Action Toy Company has decided to manufacture a new train set, the production of which is broken into six steps. The demand for the train is 4,600 units per 40-hour workweek:

Performance Time

(seconds)

Predecessors

Task

A

A

A

A

B, C

D, E

BCDEF

| 20 27 12 14 12 30

с

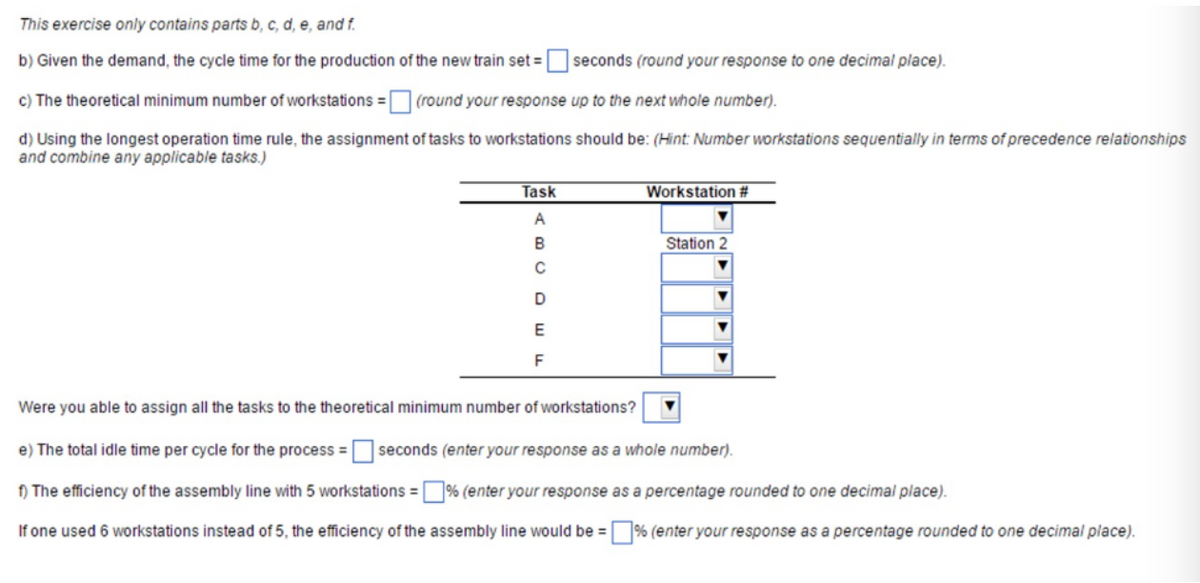

Transcribed Image Text:This exercise only contains parts b, c, d, e, and f.

b) Given the demand, the cycle time for the production

of the new train set=seconds (round your response to one decimal place).

(round your response up to the next whole number).

c) The theoretical minimum number of workstations =

d) Using the longest operation time rule, the assignment of tasks to workstations should be: (Hint: Number workstations sequentially in terms of precedence relationships

and combine any applicable tasks.)

Task

Workstation #

A

B

Station 2

C

D

E

F

Were you able to assign all the tasks to the theoretical minimum number of workstations?

e) The total idle time per cycle for the process = seconds (enter your response as a whole number).

f) The efficiency of the assembly line with 5 workstations =% (enter your response as a percentage rounded to one decimal place).

If one used 6 workstations instead of 5, the efficiency of the assembly line would be =% (enter your response as a percentage rounded to one decimal place).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Operations Management

Operations Management

ISBN:

9781259667473

Author:

William J Stevenson

Publisher:

McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi…

Operations Management

ISBN:

9781259666100

Author:

F. Robert Jacobs, Richard B Chase

Publisher:

McGraw-Hill Education

Purchasing and Supply Chain Management

Operations Management

ISBN:

9781285869681

Author:

Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:

Cengage Learning

Production and Operations Analysis, Seventh Editi…

Operations Management

ISBN:

9781478623069

Author:

Steven Nahmias, Tava Lennon Olsen

Publisher:

Waveland Press, Inc.