Two shafts, 1.67 ft apart, are connected by an open belt. The input shaft has a speed of 350 rpm and the output shaft should be capable of running at speeds of 950 rpm, 650 rpm, 450 rpm, 250 rpm, and 150 rpm. If the diameter of the smallest pulley on the driven shaft is 2 inches, calculate the length of the belt and the diameters of each pulleys attached at the shafts.

Two shafts, 1.67 ft apart, are connected by an open belt. The input shaft has a speed of 350 rpm and the output shaft should be capable of running at speeds of 950 rpm, 650 rpm, 450 rpm, 250 rpm, and 150 rpm. If the diameter of the smallest pulley on the driven shaft is 2 inches, calculate the length of the belt and the diameters of each pulleys attached at the shafts.

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter2: Axially Loaded Members

Section: Chapter Questions

Problem 2.2.11P: A small lab scale has a rigid L-shaped frame ABC consisting of a horizontal arm AB (length b = 10...

Related questions

Question

Please solve ellaborately using the equation provided in the figure and include the untis in every step, show diagram and write your solutions clearly and readable if your solution is in written form. Your work will be appreaciated much. Thank You.

Two shafts, 1.67 ft apart, are connected by an open belt. The input shaft has a speed of 350 rpm and the output shaft should be capable of running at speeds of 950 rpm, 650 rpm, 450 rpm, 250 rpm, and 150 rpm. If the diameter of the smallest pulley on the driven shaft is 2 inches, calculate the length of the belt and the diameters of each pulleys attached at the shafts.

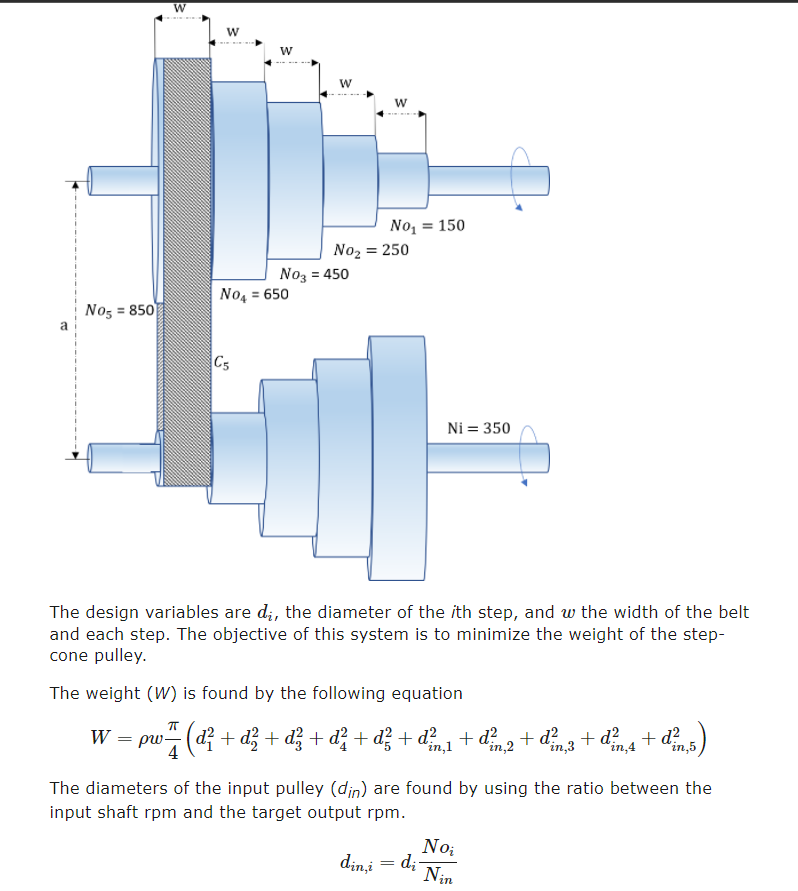

Transcribed Image Text:W

W

No, = 150

No2 = 250

Noz = 450

No4 = 650

No, = 850

Cs

Ni = 350

The design variables are d;, the diameter of the ith step, and w the width of the belt

and each step. The objective of this system is to minimize the weight of the step-

cone pulley.

The weight (W) is found by the following equation

W = pw÷(d + d; + d; + d?+ d? + d?,+d? ,+ d? + d?n+ d?

in,4

in,5

'in,1

"in,2

"in,3

The diameters of the input pulley (din) are found by using the ratio between the

input shaft rpm and the target output rpm.

No;

dini = d;-

Nin

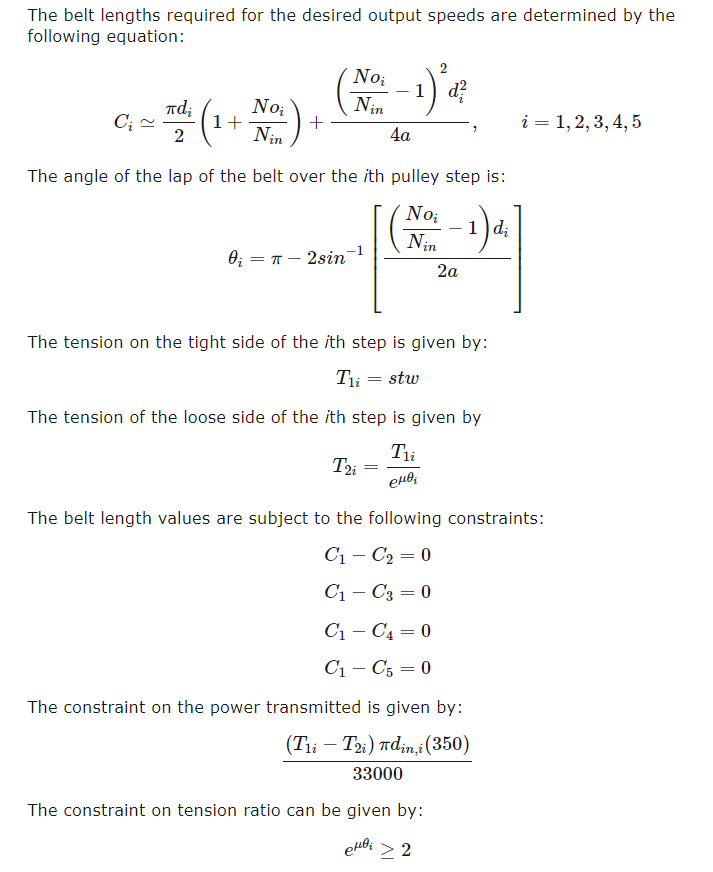

Transcribed Image Text:The belt lengths required for the desired output speeds are determined by the

following equation:

No;

-1

Nin

d?

Td;

C; -

2

No;

1+

+

Nin

i = 1,2, 3, 4, 5

4а

The angle of the lap of the belt over the ith pulley step is:

No;

d;

Nin

0; = T – 2sin

2a

The tension on the tight side of the ith step is given by:

Ti = stw

The tension of the loose side of the ith step is given by

Tii

The belt length values are subject to the following constraints:

C1 – C2 = 0

C1 – C3 = 0

C1 – C4 = 0

C1 – C5 = 0

The constraint on the power transmitted is given by:

(Tii – Ti) rdin,i(350)

33000

The constraint on tension ratio can be given by:

> 2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps

Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L