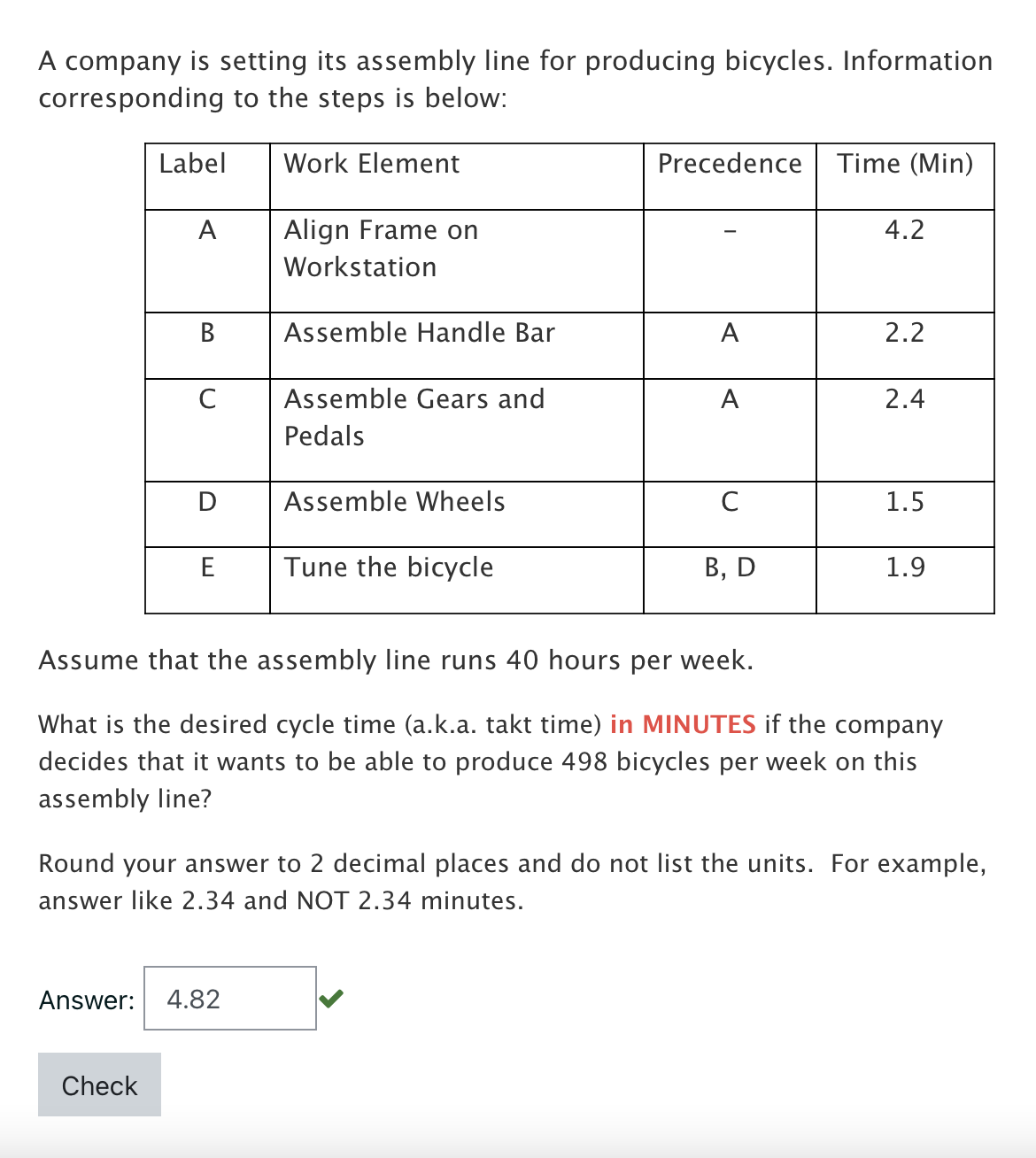

What is the desired cycle time (a.k.a. takt time) in MINUTES if the company decides that it wants to be able to produce 498 bicycles per week on this assembly line?

Q: A process that is in control has a mean of 13 and a standard deviation of .7. a. Construct an x…

A: Given data: Mean μ=13 S.D σ= 0.7 Sample Size n = 3

Q: Activities' estimated duration and the time intervals at which the actual progress is analyzed…

A: An activity's estimated duration can be defined as the approximated time that will be taken by a…

Q: When many processes are occurring simultaneously, what type of answer does the capacity analysis…

A: Capacity analysis is the difference between actual output and possible output in any process. The…

Q: Many companies say that their goal is to provide quality products or services. What actions might…

A: As per the case, the company XYZ is the hotel company that focuses on quality services and win the…

Q: At Webster Chemical, lumps in the caulking compound could cause difficulties in dispensing a smooth…

A: A C-bar control chart is a type of control chart that is used to monitor production processes. It is…

Q: Explain any two process technologies for materials. Discuss any three factors that will help to…

A: Material processing is a term used for a defined set of processes or operations that help in the…

Q: Bindley Corporation has a one-year contract to supply motors for all washing machines produced by…

A: Build transportation grid as follows.

Q: For the data set Download data set, perform exponential smoothing with alpha = 0.1 to determine the…

A: Given the data stated below, for this dataset, I would perform the exponential smoothing forecast,…

Q: There are two companies manufacturing drones. Company A manufactures mass market drones, while…

A: Find the Calculations methods: Actual production = Total production - % of Defectives Calculations:…

Q: A sampling of the output of a billing process discovered that 5,200 out of 42,000 invoices contained…

A: Given, Sample size = 42000 Errors in sample = 5200 42000 -> 5200 1000000 -> ?

Q: Flores Manufacturing, Inc., is moving to kanbans to support its electronic-board assembly lines.…

A: Ans) Input Data: Setup Cost= S = $16 Annual Holding Cost subassembly = H = $250 Daily Production = p…

Q: Measure the single-factor labour productivity and single-factor equipment productivity for the two…

A: Productivity is a measure of economic efficiency. It is usually measured as output per unit of…

Q: Explain the concept of Liquidation Strategy?

A: Liquidation Strategy Define - it is the type of strategy in which businesses sell their assets in…

Q: Colonial Furniture produces hand-crafted colonial style furniture. Plans are now being made for the…

A: Based on the given question, the following model can be built in excel. The model will be as…

Q: there are numerous methods of gathering evidence of a students or candidates performance ,…

A: Performance is the act of establishing an output/outcome by utilizing the power of all available and…

Q: Wants to build one centrally-located processing facility to serve the county's four recycling…

A: The center of gravity method for location strategy is a decision-making process that uses…

Q: Produce a detailed Maslow's motivational strategy for an organization that addresses intrinsic and…

A: The Maslow Hierarchy of Needs is related to a person's motivation. According to this idea, a person…

Q: Describe a service experience where operations related issues resulted in an service product that…

A: In an organization, no department can work in isolation to other departments. Every department is…

Q: What are some of the approaches of positioning products and services?

A: A service seems to be an intangible good that results from the labor of one or more people, whereas…

Q: rite a paragraph explaining Why Schedule flexibility is important in the workplace??

A: There are certain agreements among the employees and employee in every organization that defines the…

Q: Ch. 5. Refer to the following hypothetical transitional matrix of the general HR department in a…

A: The transition matrix is one tool to determine the employee supply in the organization. It shows the…

Q: 11.3. A commuter airline overbooks all of its flights by one passenger (i.e., the ticket agent will…

A: Critical fractile = Cu / (Cu + Co) Cu = Cost of underbooking = $20 Co = Cost of overbooking

Q: If the duration of each activity is known with certainty, then the critical path method can be used…

A: A network diagram related to the project shows the sequence of the task that is performed to…

Q: According to the EOQ and increase in interest rates would tend to....? A: increase the number of…

A: Here, I want to increase the Interest rate, The yearly carrying cost for each unit is =The cost…

Q: Explain why it is important for Jaguar to have an accurate BOM structure for their new Jaguar SType…

A: BOM - also known as product tree structure in which all the items which are needed for developing or…

Q: Suppose that a task in a project has the following time estimates: to=optimistic completion…

A: Given, Optimistic time (o) = 9 weeks Most likely time (m) = 17 weeks Pessimistic time (p) = 21 weeks

Q: why do we need to determine the demographic profile of the customers of a resort business when…

A: "Since you have asked multiple questions, we will answer the first question for you. If you want any…

Q: Suppose that you are using a 3-sigma p chart to monitor the percentage of times that you fail to get…

A: Given: n= 15 p bar = 6/15 = 0.4

Q: Mr. John produces a special type of shoes on an assembly line. The process involves eight different…

A: To ensure the smooth flow of work in a product line, assigning tasks to workstations with…

Q: Determination of the reorder point?

A: Reorder points are essential for any company that wishes to manage its inventory effectively. Making…

Q: A regional bank training centre has the physical ability to handle 1,300 participants. However,…

A: Given, Actual output = 990 participants Effective capacity = 1100 participants Design capacity =…

Q: Mr. Jack is in the process of expanding his manufacturing business. He decided to open a plant in…

A: a) i) Location A : 60000+30x Location B : 80000+20x Location C : 100000+15x Location D :…

Q: Your firm would like to purchase a very important piece of equipment from a supplier in South…

A: “Since you have asked multiple questions, we will solve the first question for you. If you want any…

Q: 9.1-3.* Tom would like 3 pints of home brew today and an addi- tional 4 pints of home brew tomorrow.…

A: Find the Transportation table below: Today Tomorrow Supply Dick 3 2.7 5 Harry 2.9 2.8 4…

Q: WHY GRAF LCL 0

A: The charts which are operated to routinely calculate the exact quality of product lots are…

Q: c. Distinguish between design capacity and effective capacity. Provide a brief example. d. Why is…

A: Design Capacity Vs Effective Capacity: Design Capacity: Design capacity is defined…

Q: Five batteries were taken in each sample to measure how long (in hours) every battery will last. The…

A:

Q: ...4.19 Income at the architectural firm Spraggins and Yunes for the period February to July was as…

A: Formulae used: The trend-adjusted exponential forecasting is given by AFt = Ft + Tt Where, Ft =…

Q: When selecting date units for grouping, users can select multiple units of measure. O True False

A: Grouping the data helps to interpret the data easily. In case of huge data, it saves time to…

Q: Briefly explain what are the roles of cGMP in the Quality Control (QC) unit in the pharmaceutical…

A: The Food and Drug Administration has established Current Good Manufacturing Practice guidelines,…

Q: why organizations maintain raw material inventory

A: Companies that produce things for a profit must endeavor to ensure effective raw material management…

Q: is it possible to show the formula in a excel spreadsheet, so i can have a better understanding.

A: Formulae used: Adjusted exponential smoothing method:- Ft=FITt-1+ α (At-1 – FITt-1) Tt= Tt-1+ β(Ft–…

Q: Solve the following linear programming problem using simplex method. A diet for a sick person must…

A: Let Food A = x1 and Food B = x2

Q: Consider the following dual problem Minimize Z = 7x₁ + 2x₂ + 5x3+4x4 subject to 2x₁ + 4x₂ + 7x3 + x4…

A: Min Z = 7 x1 + 2 x2 + 5 x3 + 4 x4 subject to 2 x1 +…

Q: The following data give the ages (in years) of all six members of a family. 58 51 28 27 22 12…

A: The given data is 58, 51, 28, 27, 22 and 12 to calculate the mean. Population Mean is the value of…

Q: Problem 12-5 (Algo) Garden Varlety Flower Shop uses 810 clay pots a month. The pots are purchased at…

A: Given data Monthly Demand (d) = 810 clay pots Annual demand (D) = Monthly Demand× No. of months in a…

Q: Case Study: Investments in African startups are on the up year-on-year, with funding flooding into…

A: Acquisition is a concept where one organization wholly or partially acquires services of the other…

Q: What type of control chart should be used to monitor the process dispersion?

A: a. p-chart:- This chart is used to control the fraction of defectives. b. range chart:- In this…

Q: a) Identify verbally the decisions to be made, the objective and the constraints( b) Formulate the…

A: As per Bartleby guidelines, we can only solve the first three subparts of one question at a…

Q: A teller at a drive-up window at a bank had the following service times (in minutes) for 20 randomly…

A: Find the Given details below: Samples Observations 1 2 3 4 1 4.5 4.6 4.5 4.7 2 4.2 4.5 4.6…

Step by step

Solved in 3 steps

- A company needs to design an assembly line to produce portable electric generators. They plan to use the assembly-line 6 hours each day to produce 2160 generators daily. The following table describes the tasks involved in the assembly of portable electric generator: IMMEDIATE TASK PREDECESSORS TIME (seconds) ==== =========== ============== a none 3 b none 5 c a,b 6 d none 7 e c,d 9 Use the Longest Processing Time Rule (LPT) to design this assembly line. How many workstations are required by your design?…(Please do not give solution in image format thanku) Develope a 3 level work breakdwon structure (including level 1,2 and 3) the work break down structure is based on the following project. Improving Customer Service Response Time for a clothing company. additional informationa can be added to the work break down struture to create the different levels The motivation behind this project is to improve customer satisfaction by reducing response time for customer service inquiries. Currently, customers are waiting an average of 48 hours to receive a response to their inquiries, resulting in frustration and dissatisfaction. By implementing a new customer service ticketing system and training customer service agents on effective communication and problem-solving techniques, response time can be reduced to 24 hours or less.A product is completed when 18 tasks are done. These tasks are assigned to 6 workstations (each workstation handling several tasks) in an assembly line set up. All workstations work the same amount of time (= cycle time), and move the (partial) product to the next workstation, and repeat this process. The last workstation generates the finished product. We need 1200 units made every day (= 8 hours). If we run this line with a cycle time of 0.3 minutes, what is the most amount of work (in minutes) that can be done on this product? (Give the answer with one decimal place)

- The desired daily output for an assembly line is 540 units. This assembly line will operate 720 minutes per day. The following table contains information on this product's task times and precedence relationships: TASK TASK TIME(SECONDS) IMMEDIATEPREDECESSOR A 35 — B 25 A C 35 A D 55 B E 5 B F 15 C G 30 E-D H 5 F-G b. What is the workstation cycle time? c. Balance this line using the largest number of following tasks. Use the longest task time as a secondary criterion. (Leave no cells blank - be certain to enter "0" wherever required.)XYZ Company produces and sells 2 products, Lambda and Gamma, and the production process goes through two departments. Traditionally Manufacturing Overhead (M/O) cost is applied on the basis of direct labor hours (DLH); estimated M/O cost is $ 5,757,500 and the estimated DLH is $12,250 for the most recent period.The team decided to replace traditional plantwide costing system to activity-based costing system. There are 3 activity cost pools which represent 3 activity areas at the plant. Direct Labor wage rate is $ 30 per hour. Compute total cost per unit (for lambda and gamma) using activity-based approach. (round your numbers).Francis Johnson’s plant needs to design an efficient assembly line to make a new product. The assembly line needs to produce 15 units per hour, and there is room for only four workstations. The tasks and the order in which they must be performed are shown in the following table. Tasks cannot be split, and it would be too expensive to duplicate any task. TASK TASK TIME (MINUTES) IMMEDIATE PREDECESSOR A 1 — B 2 — C 3 — D 1 A, B, C E 3 C F 2 E G 3 E What is the workstation cycle time required to produce 15 units per hour? Note: Round your answer to 1 decimal place. Balance the line to use the fewest possible workstations to meet the cycle time found in part (b). Use whatever method you feel is appropriate. What is the efficiency of your line balance, assuming the line operates at the cycle time from part (b)? Note: Round your answer to 1 decimal place.

- Bill builds benches in a small shop and he plans to operate five 8-hour days perweek. Each bench has two ends and a top. It takes 5 minutes to cut and sand eachend and 2 minutes to make each top. Assembly requires 8 minutes per bench, andpainting requires 5 minutes per bench. Bill has one employee who makes the topsand ends. Bill will do the final assembly and painting. He also plans 1 hour per dayfor setup and teardown for each department.a. How many benches should he plan to build per week?b. How many hours per week are required for each person?c. Suggest ways to increase the number of benches produced per weekSuppose you are going to develop a system to plan a graduation ceremony. By using an activity diagram, model the process context for such a system that shows the activities involved in it (booking a place, planing the decoration, organizing the invitations, etc.) please solve it quicklyBalance the assembly line shown below for (a) a shift output of 60 pieces and (b) a shift output of 40 pieces. Assume an 8-hour shift, and use the rule: choose the assignable task with the longest processing time. Compute the line efficiency for each case. Fill in the table below for a shift output of 60 pieces. Break ties by choosing the lowest task number. If your answer is zero, enter "0". Round your answers to the nearest whole number. Workstation Tasks Total Time Idle Time 1 2 3 4 Total What is the assembly-line efficiency? Round your answer to one decimal place. % Fill in the table below for a shift output of 40 pieces. Break ties by choosing the lowest task number. If your answer is zero, enter "0". Round your answers to the nearest whole number. Workstation Tasks Total Time Idle Time 1 2 3 Total What is the assembly-line efficiency? Round your answer to one decimal place. %

- Sue Helms Appliances wants to establish an assem-bly line to manufacture its new product, the Micro Popcorn Popper. The goal is to produce five poppers per hour. The tasks,task times, and immediate predecessors for producing one MicroPopcorn Popper are as follows:TASK TIME (min) IMMEDIATEPREDECESSORSA 10 —B 12 AC 8 A, BD 6 B, CE 6 CF 6 D, Ea) What is the theoretical minimum for the smallest number ofworkstations that Helms can achieve in this assembly line?b) Graph the assembly line, and assign workers to workstations.Can you assign them with the theoretical minimum?c) What is the efficiency of your assignment?A company needs to rebalance a product layout for producing new plastic license plates. They plan to use the assembly line six hours in order to meet projected demand of 2,160 license plates each day. The following table describes the tasks involved in the production of this product: Without regard to projected demand, what is the maximum possible cycle time for this assembly line? Task Time (secs) Immediate Predecessor a 3 none b 4 none c 5 a,b d 7 none e 9 c,dcan someone help me with this: As Patrick Sportwear Co. completes plans for its new assembly line in Liverpool, it identifies 30 different tasks in the production process. VP of Operations Kevin Keegan now faces the job of balancing the line. He lists precedences and provides time estimates for each step based on work-sampling techniques. His goal is to produce 1.000 football shoes per standard 35-hour workweek. Task Time (sec) Immediate Predecessors Task Time (sec) Immediate Predecessors B1 50 - E2 18 G5, F3 K4 24 B1 A4 10 E1 K9 27 B1 E3 109 F3 J1 66 B1 D6 53 F4 C2 12 - D7 72 F9, E2, E3, K9 J2 22 B1 C1 78 F7, A4 J3 3 C2 D8 78 E3, D6 D5 6 - D9 37 D6, A4 G4 79 K4, K9 C3 40 F9, D7 G5 29 K9, J1 B3 72 D7, D8, D9, C1 F3 32 J2 B5 108 C1 F4 92 J2 A1 52 B5 F7 21 J3 B7 18 A1, B3, C3 E1 20 C2…