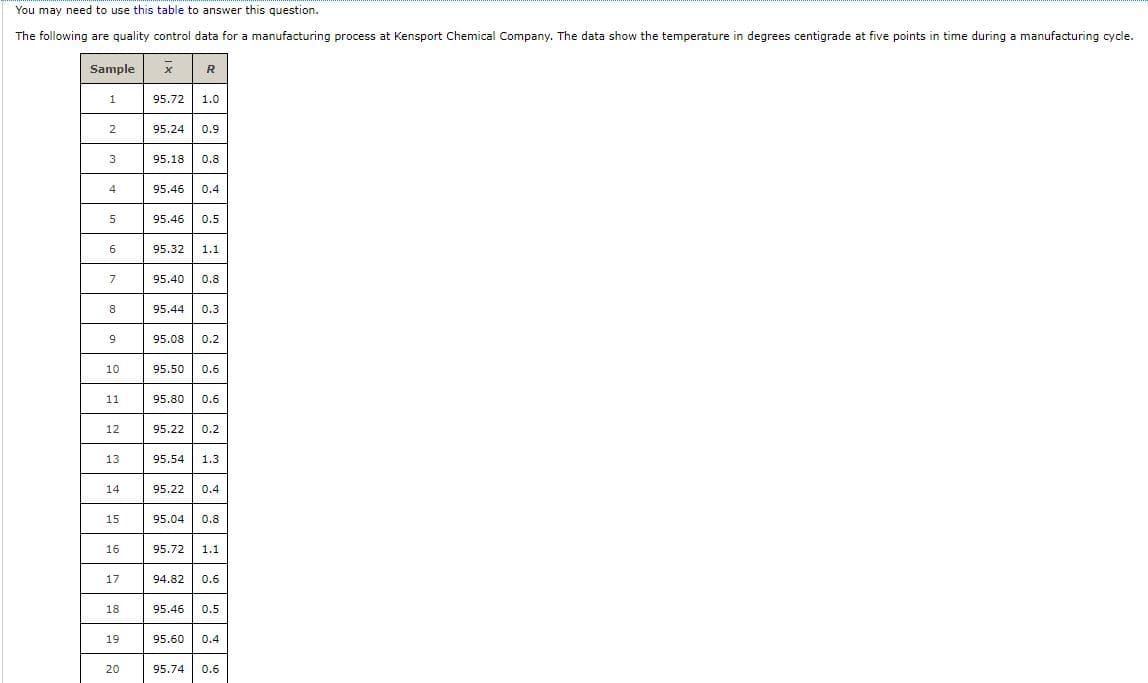

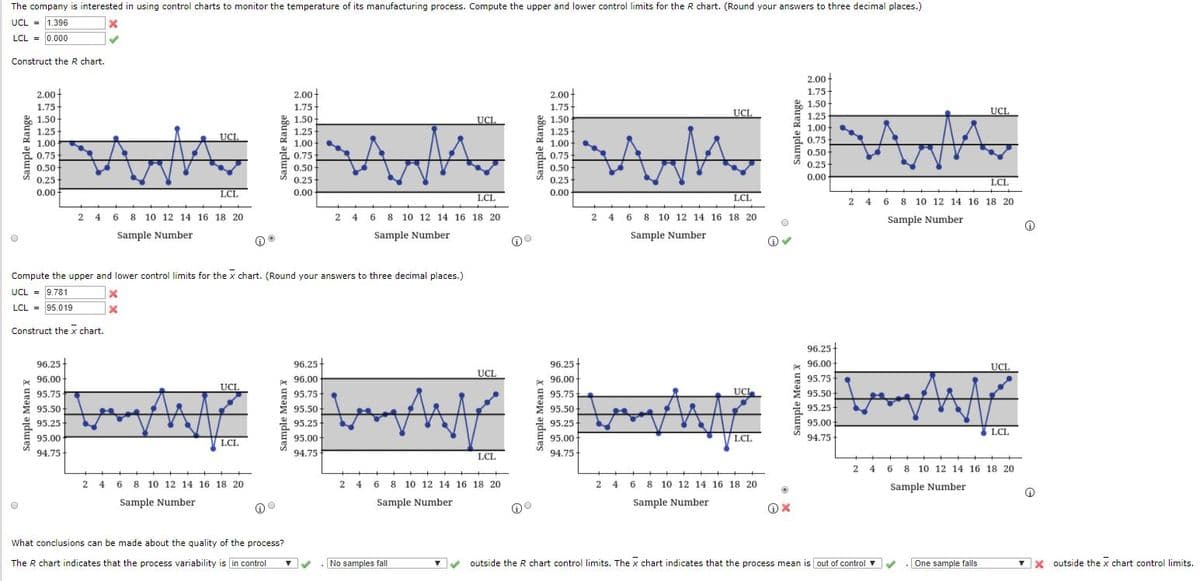

You may need to use this table to answer this question. The following are quality control data for a manufacturing process at Kensport Chemical Company. The data show the temperature in degrees centigrade at five points in time during a manufacturing cycle. Sample 95.72 1.0 1 95.24 0.9 3 95.18 0.8 4 95.46 0.4 95.46 0.5 6. 95.32 1.1 7 95.40 | 0.8 8 95.44 0.3 95.08 0.2 10 95.50 0.6 11 95.80 0.6 12 95.22 0.2 13 95.54 1.3 14 95.22 0.4 15 95.04 0.8 16 95.72 1.1 17 94.82 0.6 18 95.46 0.5 19 95.60 0.4 20 95.74 0.6

Inverse Normal Distribution

The method used for finding the corresponding z-critical value in a normal distribution using the known probability is said to be an inverse normal distribution. The inverse normal distribution is a continuous probability distribution with a family of two parameters.

Mean, Median, Mode

It is a descriptive summary of a data set. It can be defined by using some of the measures. The central tendencies do not provide information regarding individual data from the dataset. However, they give a summary of the data set. The central tendency or measure of central tendency is a central or typical value for a probability distribution.

Z-Scores

A z-score is a unit of measurement used in statistics to describe the position of a raw score in terms of its distance from the mean, measured with reference to standard deviation from the mean. Z-scores are useful in statistics because they allow comparison between two scores that belong to different normal distributions.

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 3 images