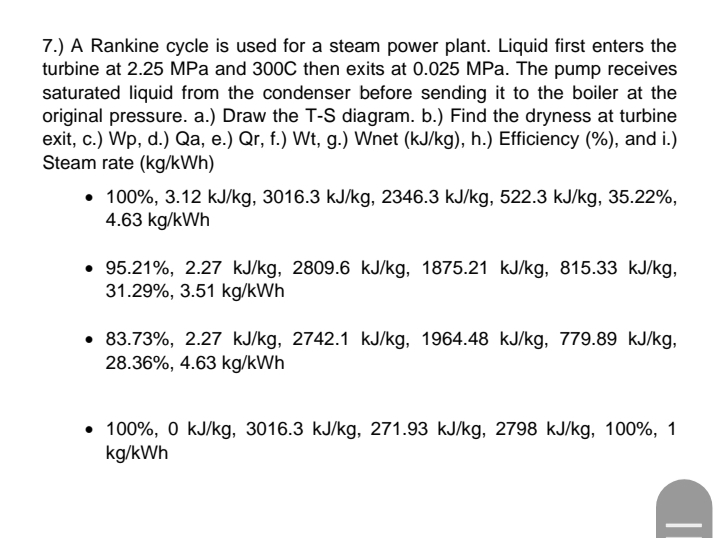

7.) A Rankine cycle is used for a steam power plant. Liquid first enters the turbine at 2.25 MPa and 300C then exits at 0.025 MPa. The pump receives saturated liquid from the condenser before sending it to the boiler at the original pressure. a.) Draw the T-S diagram. b.) Find the dryness at turbine exit, c.) Wp, d.) Qa, e.) Qr, f.) Wt, g.) Wnet (kJ/kg), h.) Efficiency (%), and i.) Steam rate (kg/kWh) • 100%, 3.12 kJ/kg, 3016.3 kJ/kg, 2346.3 kJ/kg, 522.3 kJ/kg, 35.22%, 4.63 kg/kWh • 95.21%, 2.27 kJ/kg, 2809.6 kJ/kg, 1875.21 kJ/kg, 815.33 kJ/kg, 31.29%, 3.51 kg/kWh • 83.73%, 2.27 kJ/kg, 2742.1 kJ/kg, 1964.48 kJ/kg, 779.89 kJ/kg, 28.36%, 4.63 kg/kWh • 100%, 0 kJ/kg, 3016.3 kJ/kg, 271.93 kJ/kg, 2798 kJ/kg, 100%, 1 kg/kWh

7.) A Rankine cycle is used for a steam power plant. Liquid first enters the turbine at 2.25 MPa and 300C then exits at 0.025 MPa. The pump receives saturated liquid from the condenser before sending it to the boiler at the original pressure. a.) Draw the T-S diagram. b.) Find the dryness at turbine exit, c.) Wp, d.) Qa, e.) Qr, f.) Wt, g.) Wnet (kJ/kg), h.) Efficiency (%), and i.) Steam rate (kg/kWh) • 100%, 3.12 kJ/kg, 3016.3 kJ/kg, 2346.3 kJ/kg, 522.3 kJ/kg, 35.22%, 4.63 kg/kWh • 95.21%, 2.27 kJ/kg, 2809.6 kJ/kg, 1875.21 kJ/kg, 815.33 kJ/kg, 31.29%, 3.51 kg/kWh • 83.73%, 2.27 kJ/kg, 2742.1 kJ/kg, 1964.48 kJ/kg, 779.89 kJ/kg, 28.36%, 4.63 kg/kWh • 100%, 0 kJ/kg, 3016.3 kJ/kg, 271.93 kJ/kg, 2798 kJ/kg, 100%, 1 kg/kWh

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

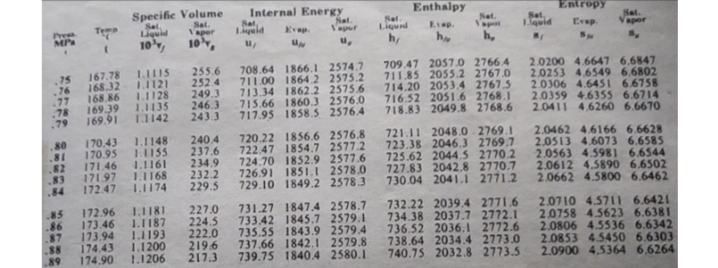

Use the steam table provided and DO NOT round the values from steam tables. Write down the values taken down from the steam table.

Transcribed Image Text:Specific Volume

Enthalpy

Internal Energy

Sat

Liguid

Entropy

Sal

Sat.

Vapur

Sat.

Press

MP

Te

Liquid

Vaper

Set

Liqurd

Sat.

Set,

LSquid

Sal.

Vapor

Evap.

Esap.

Evap.

10,

10,

h,

708.64 1866.1 2574.7

252.4 711.00 1864 2 2575.2

713.34 1862.2 2575.6

715.66 1860.3 2576.0

717.95 1858.5 2576.4

709.47 2057.0 2766 4

711.85 2055.2 2767.0 2.0253 4.6549 6.6802

714.20 2053.4 2767.5

716.52 2051.6 2768.1 2.0359 4.6355 6.6714

718.83 2049.8 2768.6

167.78

255.6

2.0200 4.6647 6.6847

15

76 168.32 LI121

.77

78

79

168.86 1.1128

169 39

169.91 1J142 243.3

249.3

1.1135 246.3

2.0306 4.645I 6.6758

2.0411 4.6260 6.6670

.80

.81

82

83

.84

170.43 1.1148

170.95 11155

171.46 1.1161

171.97 1.1168

172.47 1.1174

240,4

237.6

234.9

232.2

229.5

720.22 1856.6 2576.8

722.47 1854.7 2577.2

724.70 1852.9 2577.6

726.91 1851,I 2578.0

729.10 1849.2 2578.3

721.11 2048.0 2769.1 2.0462 4.6166 6.6628

723,38 2046.3 27697 2,0513 4.6073 6.6585

725.62 2044.5 2770.2 2.0563 4.5981 6.6544

727.83 2042.8 2770.7 2.0612 4.5890 6.6502

730.04 2041.I 2771.2 2.0662 4.5800 6.6462

.85

.86

87

.38

89

173.94

174.43

174.90

172.96 1.1181 227.0

173.46 1.1187

L.1193

1.1200

1.1206

224.5

222.0

219.6

217.3

731.27 1847.4 2578.7

733.42 1845.7 2579.1

735.55 1843.9 2579.4

737.66 1842.1 2579.8

739.75 1840.4 2580.1

732.22 2039.4 2771.6 2.0710 4.5711 6.6421

734.38 2037.7 2772.1 2.0758 4.5623 6.6381

736.52 2036.I 2772.6 2.0806 4.5536 6.6342

738.64 2034.4 2773.0

740.75 2032.8 2773.5

2.0853 4.5450 6.6303

2.0900 4,5364 6,6264

Transcribed Image Text:7.) A Rankine cycle is used for a steam power plant. Liquid first enters the

turbine at 2.25 MPa and 300C then exits at 0.025 MPa. The pump receives

saturated liquid from the condenser before sending it to the boiler at the

original pressure. a.) Draw the T-S diagram. b.) Find the dryness at turbine

exit, c.) Wp, d.) Qa, e.) Qr, f.) Wt, g.) Wnet (kJ/kg), h.) Efficiency (%), and i.)

Steam rate (kg/kWh)

• 100%, 3.12 kJ/kg, 3016.3 kJ/kg, 2346.3 kJ/kg, 522.3 kJ/kg, 35.22%,

4.63 kg/kWh

• 95.21%, 2.27 kJ/kg, 2809.6 kJ/kg, 1875.21 kJ/kg, 815.33 kJ/kg,

31.29%, 3.51 kg/kWh

• 83.73%, 2.27 kJ/kg, 2742.1 kJ/kg, 1964.48 kJ/kg, 779.89 kJ/kg,

28.36%, 4.63 kg/kWh

• 100%, 0 kJ/kg, 3016.3 kJ/kg, 271.93 kJ/kg, 2798 kJ/kg, 100%, 1

kg/kWh

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY