A company that makes shopping carts for supermarkets and other stores recently purchased some new equipment that reduces the labor content of the jobs needed to produce the shopping carts. Prior to buying the new equipment, the company used 6 workers. who together produced an average of 70 carts per hour. Workers receive $18 per hour, and machine cost was $30 per hour. With the new equipment, it was possible to transfer one of the workers to another department, and equipment cost increased by $11 per hour. while output Increased by 5 carts per hour. a. Compute labor productivity under each system. Use carts per worker per hour as the measure of labor productivity. (Round your answers to 3 decimal places.) Before After b. Compute the multifactor productivity under each system. Use carts per dollar cost (labor plus equipment) as the measure. (Round your answers to 3 decimal places.) Before After carts per worker per hour carts per worker per hour Labor productivity Multifactor productivity carts/dollar cost carts/dollar cost c. Comment on the changes in productivity according to the two measures. (Round your Intermediate calculations to 3 decimal places and final answers to 2 decimal places.) by by

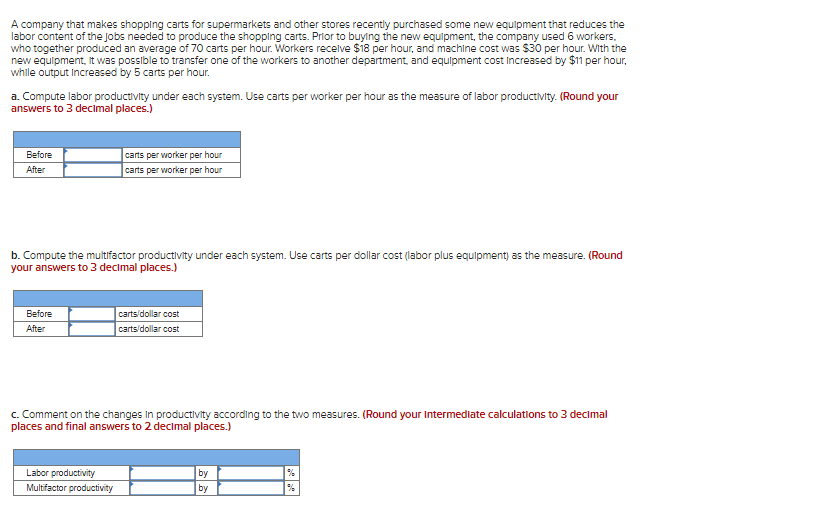

A company that makes shopping carts for supermarkets and other stores recently purchased some new equipment that reduces the labor content of the jobs needed to produce the shopping carts. Prior to buying the new equipment, the company used 6 workers, who together produced an average of 70 carts per hour. Workers receive $18 per hour, and machine cost was $30 per hour. With the new equipment, it was possible to transfer one of the workers to another department, and equipment cost increased by $11 per hour, while output increased by 5 carts per hour.

a. Compute labor productivity under each system. Use carts per worker per hour as the measure of labor productivity. (Round your answers to 3 decimal places.)

b. Compute the multifactor productivity under each system. Use carts per dollar cost (labor plus equipment) as the measure. (Round your answers to 3 decimal places.)

c. Comment on the changes in productivity according to the two measures. (Round your intermediate calculations to 3 decimal places and final answers to 2 decimal places.)

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images