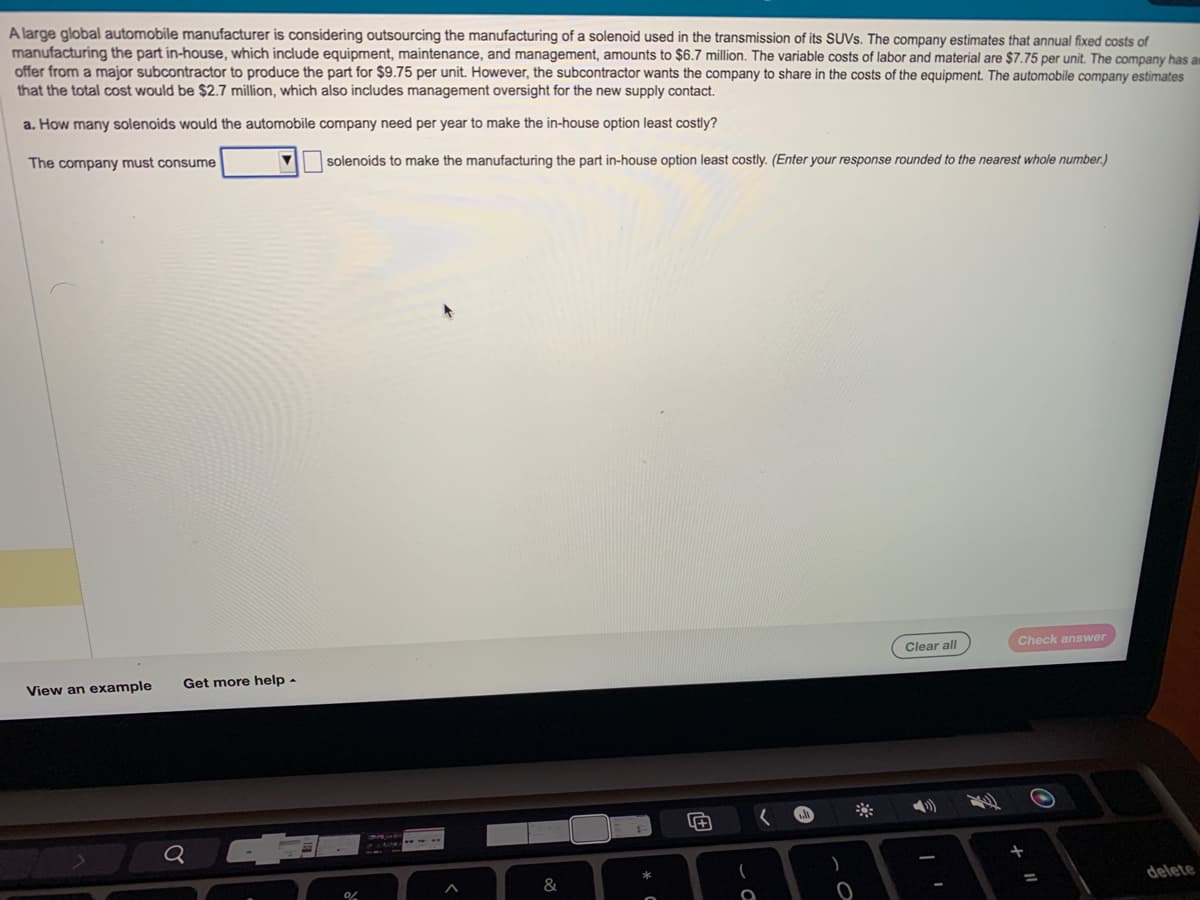

A large global automobile manufacturer is considering outsourcing the manufacturing of a solenoid used in the transmission of its SUVs. The company estimates that annual fixed costs of manufacturing the part in-house, which include equipment, maintenance, and management, amounts to $6.7 million. The variable costs of labor and material are $7.75 per unit. The company has a offer from a major subcontractor to produce the part for $9.75 per unit. However, the subcontractor wants the company to share in the costs of the equipment. The automobile company estimates that the total cost would be $2.7 million, which also includes management oversight for the new supply contact. a. How many solenoids would the automobile company need per year to make the in-house option least costly? The company must consume solenoids to make the manufacturing the part in-house option least costly. (Enter your response rounded to the nearest whole number.)

A large global automobile manufacturer is considering outsourcing the manufacturing of a solenoid used in the transmission of its SUVs. The company estimates that annual fixed costs of manufacturing the part in-house, which include equipment, maintenance, and management, amounts to $6.7 million. The variable costs of labor and material are $7.75 per unit. The company has a offer from a major subcontractor to produce the part for $9.75 per unit. However, the subcontractor wants the company to share in the costs of the equipment. The automobile company estimates that the total cost would be $2.7 million, which also includes management oversight for the new supply contact. a. How many solenoids would the automobile company need per year to make the in-house option least costly? The company must consume solenoids to make the manufacturing the part in-house option least costly. (Enter your response rounded to the nearest whole number.)

Chapter6: Target Markets: Segmentation And Evaluation

Section: Chapter Questions

Problem 4SC

Related questions

Question

Transcribed Image Text:A large global automobile manufacturer is considering outsourcing the manufacturing of a solenoid used in the transmission of its SUVs. The company estimates that annual fixed costs of

manufacturing the part in-house, which include equipment, maintenance, and management, amounts to $6.7 million. The variable costs of labor and material are $7.75 per unit. The company has an

offer from a major subcontractor to produce the part for $9.75 per unit. However, the subcontractor wants the company to share in the costs of the equipment. The automobile company estimates

that the total cost would be $2.7 million, which also includes management oversight for the new supply contact.

a. How many solenoids would the automobile company need per year to make the in-house option least costly?

The company must consume

View an example

Get more help.

Q

solenoids to make the manufacturing the part in-house option least costly. (Enter your response rounded to the nearest whole number.)

&

+

(

<

)

0

Clear all

Check answer

+

delete

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you