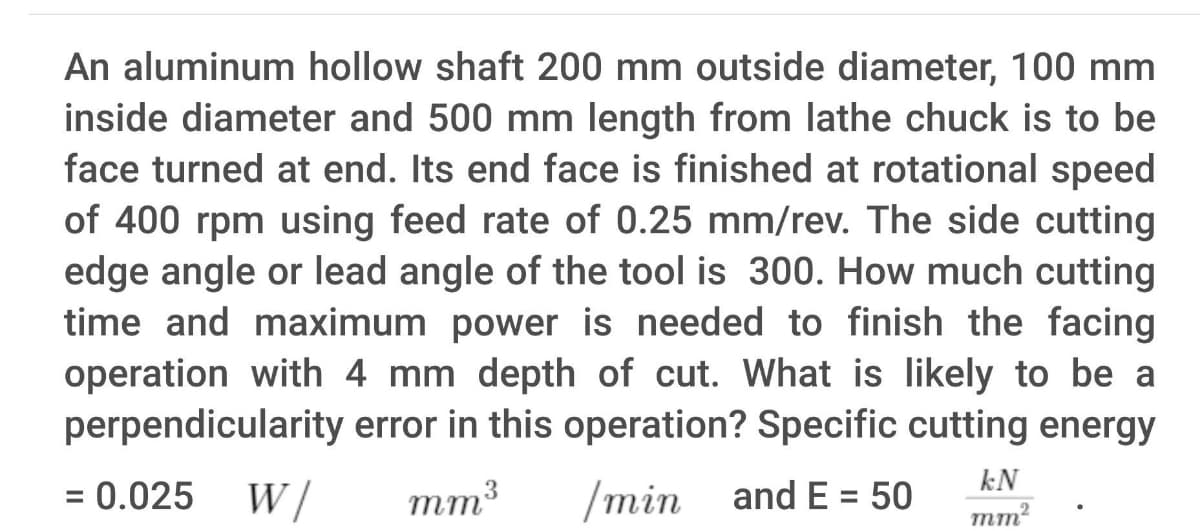

An aluminum hollow shaft 200 mm outside diameter, 100 mm inside diameter and 500 mm length from lathe chuck is to be face turned at end. Its end face is finished at rotational speed of 400 rpm using feed rate of 0.25 mm/rev. The side cutting edge angle or lead angle of the tool is 300. How much cutting time and maximum power is needed to finish the facing operation with 4 mm depth of cut. What is likely to be a perpendicularity error in this operation? Specific cutting energy kN = 0.025 W / mm3 (min and E = 50 %3D

An aluminum hollow shaft 200 mm outside diameter, 100 mm inside diameter and 500 mm length from lathe chuck is to be face turned at end. Its end face is finished at rotational speed of 400 rpm using feed rate of 0.25 mm/rev. The side cutting edge angle or lead angle of the tool is 300. How much cutting time and maximum power is needed to finish the facing operation with 4 mm depth of cut. What is likely to be a perpendicularity error in this operation? Specific cutting energy kN = 0.025 W / mm3 (min and E = 50 %3D

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter5: Turning

Section5.3: Machining Operations On The Lathe

Problem 5RQ: Calculate spindle RPM and machining time for cutting a 1.5" diameter 4" long at 225 SFPM using a...

Related questions

Question

Please answer correctly i will you 5 likes.

Transcribed Image Text:An aluminum hollow shaft 200 mm outside diameter, 100 mm

inside diameter and 500 mm length from lathe chuck is to be

face turned at end. Its end face is finished at rotational speed

of 400 rpm using feed rate of 0.25 mm/rev. The side cutting

edge angle or lead angle of the tool is 300. How much cutting

time and maximum power is needed to finish the facing

operation with 4 mm depth of cut. What is likely to be a

perpendicularity error in this operation? Specific cutting energy

kN

= 0.025

W /

mm3

/min

and E = 50

%3D

%3D

mm?

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning