Consider the device shown below that will be used to humidity an air stream. In the current process, air containing 1 mol % water vapor (species A) at 40°C and 1 atm enters the tube of 3 cm inner diameter at a velocity of 300 cm/s. A water-adsorbent material saturated with liquid water lines the inner surface of the tube. Water evaporates from this liner material as air passes over it. There is no diffusion resistance of water vapor through the liner material itself. The process is maintained at 40°C. The saturation vapor pressure of water is 55.4 mmHg at 40°C. at this temperature and 1.0 atm, the viscosity of air is 1.91x104 g/cm s and the density of air is 1.13x10-3 g/cm³. ● What is the Schmidt number for this process? Develop a model, in final integrated form, to predict the concentration of water vapor exiting the tube. The thickness of the adsorbent material lining the inner surface of the tube is 1 mm and it initially contains 0.6 g of water per cm³. If the tube is 8 m long and the humidification occurs at 40°C and 1.0 atm system pressure, determine how long this process can operate before the liquid water is depleted. You will need to determine the outlet concentration of water vapor and then perform an overall material balance to estimate the net overall rate of water vapor transferred. Gas stream v=300 cm/sec CA1 Water adsorbent liner (1.0 mm thick, 0.6 g H₂O/cm³ liner initially) D= 3.0 cm (tube) 1.0 atm, 40°C L = 8.0 m CA2

Consider the device shown below that will be used to humidity an air stream. In the current process, air containing 1 mol % water vapor (species A) at 40°C and 1 atm enters the tube of 3 cm inner diameter at a velocity of 300 cm/s. A water-adsorbent material saturated with liquid water lines the inner surface of the tube. Water evaporates from this liner material as air passes over it. There is no diffusion resistance of water vapor through the liner material itself. The process is maintained at 40°C. The saturation vapor pressure of water is 55.4 mmHg at 40°C. at this temperature and 1.0 atm, the viscosity of air is 1.91x104 g/cm s and the density of air is 1.13x10-3 g/cm³. ● What is the Schmidt number for this process? Develop a model, in final integrated form, to predict the concentration of water vapor exiting the tube. The thickness of the adsorbent material lining the inner surface of the tube is 1 mm and it initially contains 0.6 g of water per cm³. If the tube is 8 m long and the humidification occurs at 40°C and 1.0 atm system pressure, determine how long this process can operate before the liquid water is depleted. You will need to determine the outlet concentration of water vapor and then perform an overall material balance to estimate the net overall rate of water vapor transferred. Gas stream v=300 cm/sec CA1 Water adsorbent liner (1.0 mm thick, 0.6 g H₂O/cm³ liner initially) D= 3.0 cm (tube) 1.0 atm, 40°C L = 8.0 m CA2

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:hown below that will be used to humidity an air stream. In the current process, air containing

and 1 atm enters the tube of 3 cm inner diameter at a velocity of 300

ines the inner surface of the tube. Water evaporates

water vapor through the liner

+000

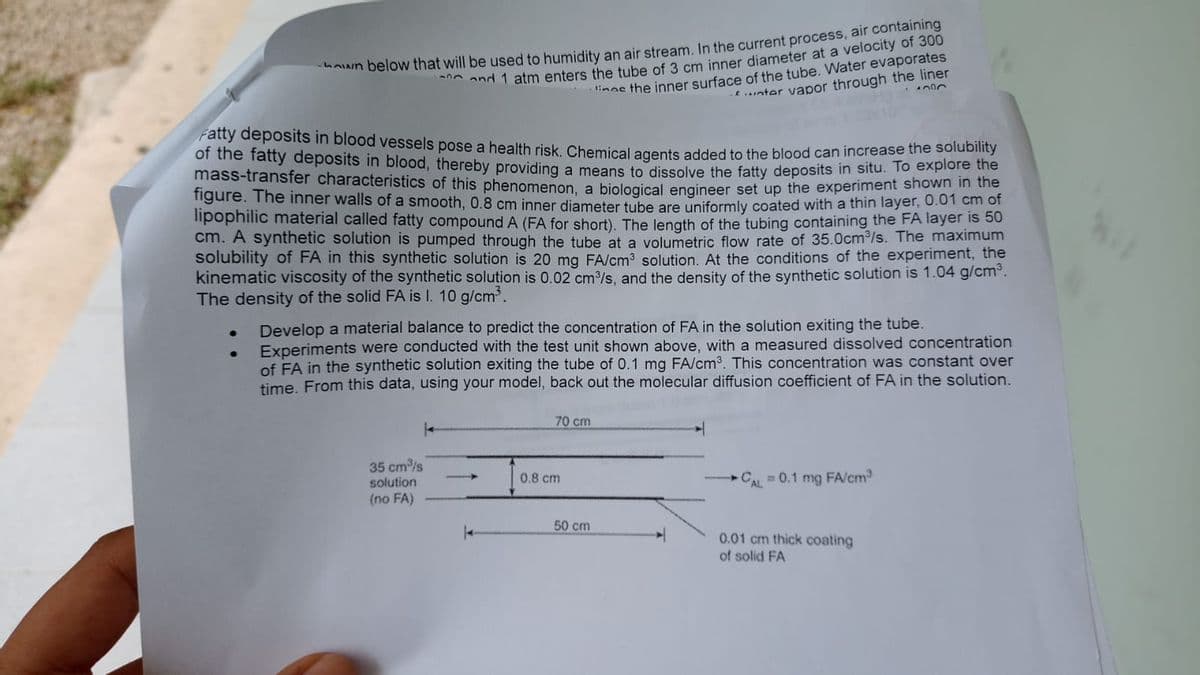

Fatty deposits in blood vessels pose a health risk. Chemical agents added to the blood can increase the solubility

of the fatty deposits in blood, thereby providing a means to dissolve the fatty deposits in situ. To explore the

mass-transfer characteristics of this phenomenon, a biological engineer set up the experiment shown

figure. The inner walls of a smooth, 0.8 cm inner diameter tube are uniformly coated with a thin layer, 0.01 cm of

lipophilic material called fatty compound A (FA for short). The length of the tubing containing the FA layer is 50

cm. A synthetic solution is pumped through the tube at a volumetric flow rate of 35.0cm³/s. The maximum

solubility of FA in this synthetic solution is 20 mg FA/cm3 solution. At the conditions of the experiment, the

kinematic viscosity of the synthetic solution is 0.02 cm³/s, and the density of the synthetic solution is 1.04 g/cm³.

The density of the solid FA is I. 10 g/cm³.

●

Develop a material balance to predict the concentration of FA in the solution exiting the tube.

Experiments were conducted with the test unit shown above, with a measured dissolved concentration

of FA in the synthetic solution exiting the tube of 0.1 mg FA/cm³. This concentration was constant over

time. From this data, using your model, back out the molecular diffusion coefficient of FA in the solution.

35 cm³/s

solution

(no FA)

70 cm

0.8 cm

50 cm

CAL = 0.1 mg FA/cm³

0.01 cm thick coating

of solid FA

Transcribed Image Text:ORGANICO

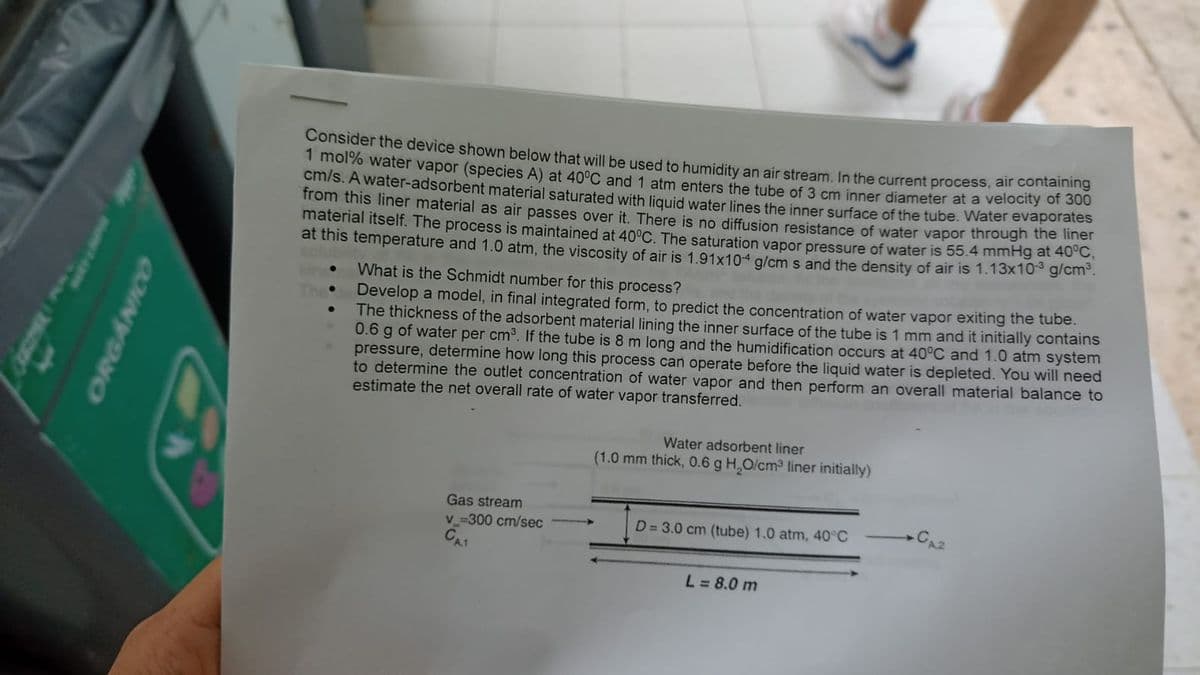

Consider the device shown below that will be used to humidity an air stream. In the current process, air containing

1 mol% water vapor (species A) at 40°C and 1 atm enters the tube of 3 cm inner diameter at a velocity of 300

cm/s. A water-adsorbent material saturated with liquid water lines the inner surface of the tube. Water evaporate

from this liner material as air passes over it. There is no diffusion resistance of water vapor through the liner

material itself. The process is maintained at 40°C. The saturation vapor pressure of water is 55.4 mmHg at 40°C,

at this temperature and 1.0 atm, the viscosity of air is 1.91x10-4 g/cm s and the density of air is 1.13x10-³ g/cm³.

●

What is the Schmidt number for this process?

Develop a model, in final integrated form, to predict the concentration of water vapor exiting the tube.

The thickness of the adsorbent material lining the inner surface of the tube is 1 mm and it initially contains

0.6 g of water per cm³. If the tube is 8 m long and the humidification occurs at 40°C and 1.0 atm system

pressure, determine how long this process can operate before the liquid water is depleted. You will need

to determine the outlet concentration of water vapor and then perform an overall material balance to

estimate the net overall rate of water vapor transferred.

Gas stream

v=300 cm/sec

CA1

Water adsorbent liner

(1.0 mm thick, 0.6 g H₂O/cm³ liner initially)

D = 3.0 cm (tube) 1.0 atm, 40°C

L = 8.0 m

CA2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 6 steps with 4 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The