Design a rigid flange coupling to transmit a torque of 257N-m between two coaxial shafts. The shaft is made of alloy steel, flanges out of cast iron and bolts out of steel. Four bolts are used to couple the flanges. The shafts are keyed to the flange hub. The permissible stresses are given below: Shear stress on shaft =100MPa Bearing or crushing stress on shaft =250MPa Shear stress on keys =100MPa Bearing stress on keys = 250MPa Shearing stress on cast iron = 200Mpa Shear stress on bolts =100MPa Answer in Word please

Design a rigid flange coupling to transmit a torque of 257N-m between two coaxial shafts. The shaft is made of alloy steel, flanges out of cast iron and bolts out of steel. Four bolts are used to couple the flanges. The shafts are keyed to the flange hub. The permissible stresses are given below: Shear stress on shaft =100MPa Bearing or crushing stress on shaft =250MPa Shear stress on keys =100MPa Bearing stress on keys = 250MPa Shearing stress on cast iron = 200Mpa Shear stress on bolts =100MPa Answer in Word please

Mechanics of Materials (MindTap Course List)

9th Edition

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Barry J. Goodno, James M. Gere

Chapter3: Torsion

Section: Chapter Questions

Problem 3.3.5P: A prospector uses a hand-powered winch (see figure) to raise a bucket of ore in his mine shaft. The...

Related questions

Question

100%

Design a rigid flange coupling to transmit a torque of 257N-m between two coaxial shafts. The shaft

is made of alloy steel, flanges out of cast iron and bolts out of steel. Four bolts are used to couple the

flanges. The shafts are keyed to the flange hub. The permissible stresses are given below:

Shear stress on shaft =100MPa

Bearing or crushing stress on shaft =250MPa

Shear stress on keys =100MPa

Bearing stress on keys = 250MPa

Shearing stress on cast iron = 200Mpa

Shear stress on bolts =100MPa

Answer in Word please

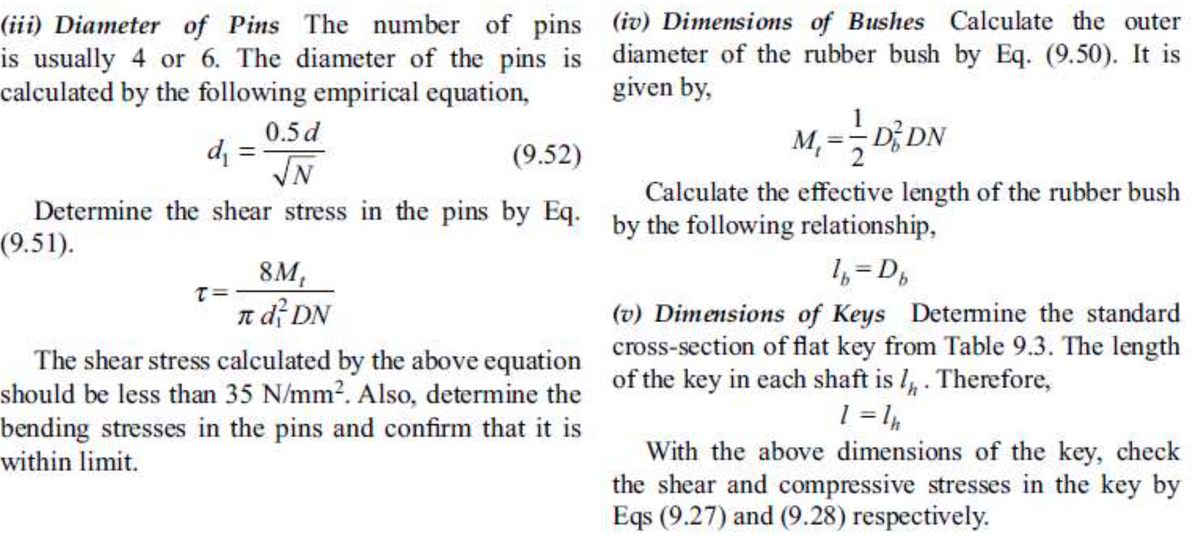

Transcribed Image Text:(iii) Diameter of Pins The number of pins (iv) Dimensions of Bushes Calculate the outer

is usually 4 or 6. The diameter of the pins is diameter of the rubber bush by Eq. (9.50). It is

calculated by the following empirical equation,

given by,

0.5d

%3D

M, =-D; DN

d =

(9.52)

N.

Calculate the effective length of the rubber bush

Determine the shear stress in the pins by Eq. by the following relationship,

(9.51).

8M,

T= -

1, =D,

n df DN

(v) Dimensions of Keys Detemine the standard

The shear stress calculated by the above equation cross-section of flat key from Table 9.3. The length

should be less than 35 N/mm?. Also, determine the of the key in each shaft is I, . Therefore,

bending stresses in the pins and confirm that it is

With the above dimensions of the key, check

the shear and compressive stresses in the key by

Eqs (9.27) and (9.28) respectively.

within limit.

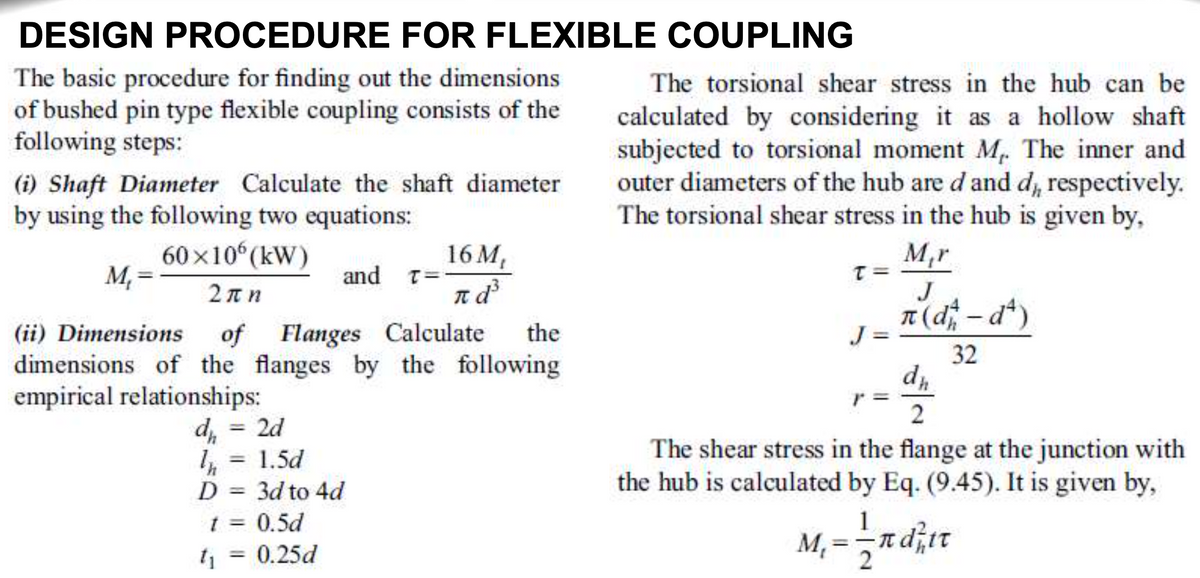

Transcribed Image Text:DESIGN PROCEDURE FOR FLEXIBLE COUPLING

The basic procedure for finding out the dimensions

of bushed pin type flexible coupling consists of the

following steps:

The torsional shear stress in the hub can be

calculated by considering it as a hollow shaft

subjected to torsional moment M. The inner and

outer diameters of the hub are d and d, respectively.

The torsional shear stress in the hub is given by,

(i) Shaft Diameter Calculate the shaft diameter

by using the following two equations:

60x10 (kW)

16 M,

and T=-

M,r

M, =

2πη

J

n(d-dt)

|

(ii) Dimensions

of Flanges Calculate

the

J =

32

dimensions of the flanges by the following

empirical relationships:

2d

%3D

The shear stress in the flange at the junction with

the hub is calculated by Eq. (9.45). It is given by,

1.5d

%3D

D = 3d to 4d

t = 0.5d

%3D

1

%3D

%3D

t = 0.25d

%3D

2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 7 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning