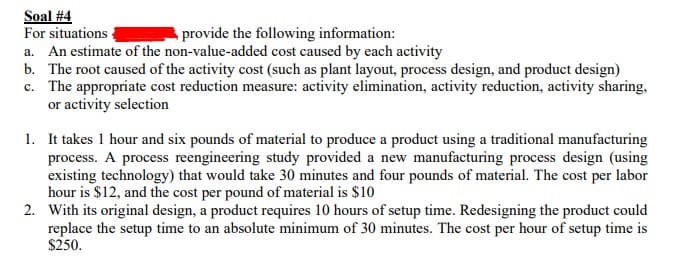

For situations provide the following information: a. An estimate of the non-value-added cost caused by each activity b. The root caused of the activity cost (such as plant layout, process design, and product design) c. The appropriate cost reduction measure: activity elimination, activity reduction, activity sharing, or activity selection 1. It takes 1 hour and six pounds of material to produce a product using a traditional manufacturing process. A process reengineering study provided a new manufacturing process design (using existing technology) that would take 30 minutes and four pounds of material. The cost per labor hour is $12, and the cost per pound of material is $10 2. With its original design, a product requires 10 hours of setup time. Redesigning the product could replace the setup time to an absolute minimum of 30 minutes. The cost per hour of setup time is $250.

For situations provide the following information: a. An estimate of the non-value-added cost caused by each activity b. The root caused of the activity cost (such as plant layout, process design, and product design) c. The appropriate cost reduction measure: activity elimination, activity reduction, activity sharing, or activity selection 1. It takes 1 hour and six pounds of material to produce a product using a traditional manufacturing process. A process reengineering study provided a new manufacturing process design (using existing technology) that would take 30 minutes and four pounds of material. The cost per labor hour is $12, and the cost per pound of material is $10 2. With its original design, a product requires 10 hours of setup time. Redesigning the product could replace the setup time to an absolute minimum of 30 minutes. The cost per hour of setup time is $250.

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter14: Quality And Environmental Cost Management

Section: Chapter Questions

Problem 6CE: Pinter Company had the following environmental activities and product information: 1. Environmental...

Related questions

Question

Transcribed Image Text:Soal #4

For situations

a. An estimate of the non-value-added cost caused by each activity

b. The root caused of the activity cost (such as plant layout, process design, and product design)

c. The appropriate cost reduction measure: activity elimination, activity reduction, activity sharing,

or activity selection

provide the following information:

1. It takes 1 hour and six pounds of material to produce a product using a traditional manufacturing

process. A process reengineering study provided a new manufacturing process design (using

existing technology) that would take 30 minutes and four pounds of material. The cost per labor

hour is $12, and the cost per pound of material is $10

2. With its original design, a product requires 10 hours of setup time. Redesigning the product could

replace the setup time to an absolute minimum of 30 minutes. The cost per hour of setup time is

$250.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning