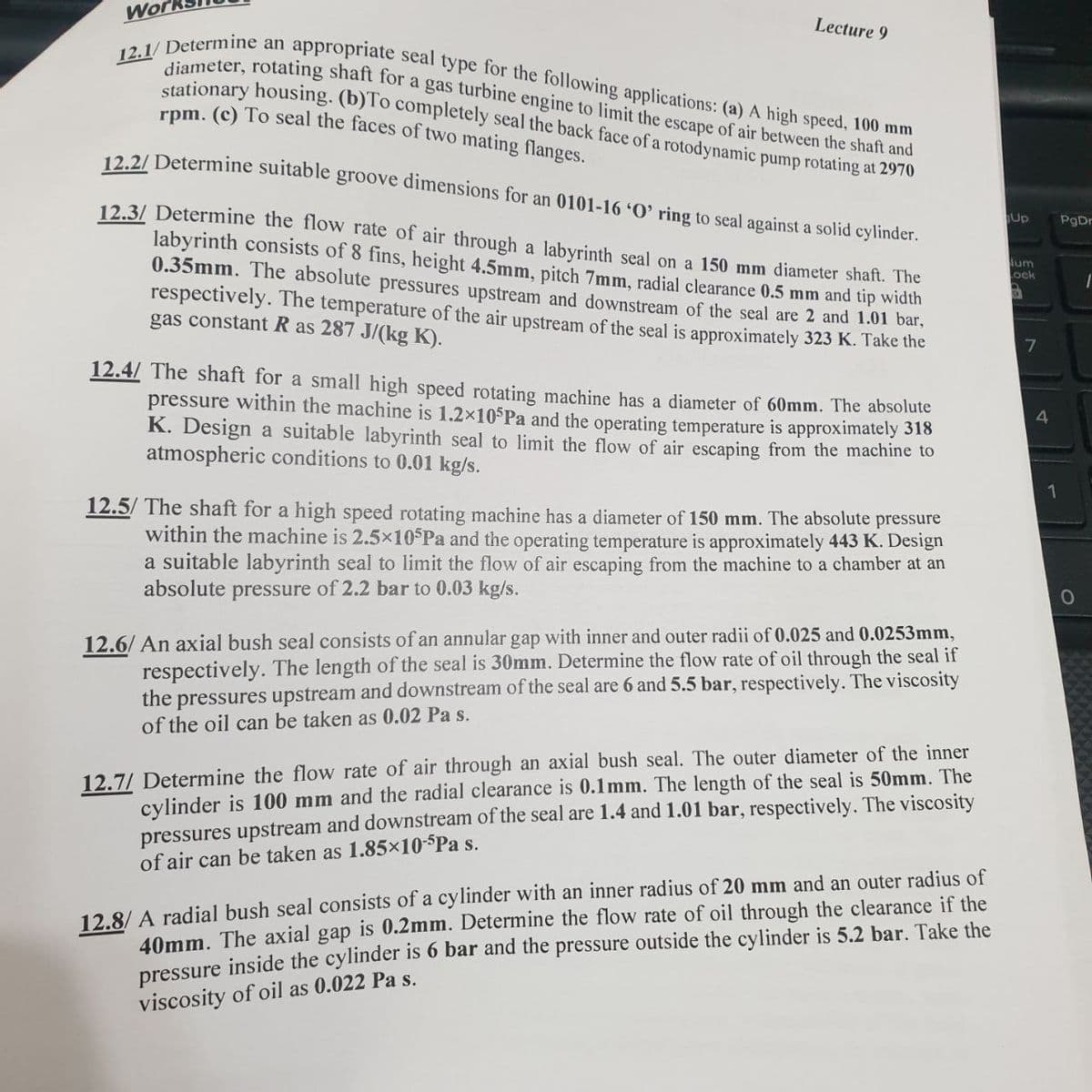

Lecture 9 rpm. (c) To seal the faces of two mating flanges. Wor diameter, rotating shaft for a gas turbine engine to limit the escape of air between the shaft and appropriate seal type for the following applications: (a) A high speed, 100 mm 12.1/ Determine an rationary housing. (b)To completely seal the back face of a rotodynamic pump rotating at 2970 12.2/ Determine suitable groove dimensions for on 011

Lecture 9 rpm. (c) To seal the faces of two mating flanges. Wor diameter, rotating shaft for a gas turbine engine to limit the escape of air between the shaft and appropriate seal type for the following applications: (a) A high speed, 100 mm 12.1/ Determine an rationary housing. (b)To completely seal the back face of a rotodynamic pump rotating at 2970 12.2/ Determine suitable groove dimensions for on 011

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

answer please

Transcribed Image Text:diameter, rotating shaft for a gas turbine engine to limit the escape of air between the shaft and

rpm. (c) To seal the faces of two mating flanges.

Wor

12.1/ Determine an

detionary housing. (b)To completely seal the back face of a rotodynamic pump rotating at 2970

Lecture 9

appropriate seal type for the following applications: (a) A high speed, 100 mm

12 2/ Determine suitable groove dimensions for an 0101-16 O' ring to seal against a solid cylinder.

12.3/ Determine the flow rate of air through a labyrinth seal on a 150 mm diameter shaft. The

labyrinth consists of 8 fins, height 4.5mm, pitch 7mm, radial clearance 0.5 mm and tip width

0.35mm. The absolute pressures upstream and downstream of the seal are 2 and 1.01 bar,

respectively. The temperature of the air upstream of the seal is approximately 323 K. Take the

gas constant R as 287 J/(kg K).

Up

PgDr

um

Lock

7

12.4/ The shaft for a small high speed rotating machine has a diameter of 60mm. The absolute

pressure within the machine is 1.2x10SPa and the operating temperature is approximately 318

K. Design a suitable labyrinth seal to limit the flow of air escaping from the machine to

atmospheric conditions to 0.01 kg/s.

12.5/ The shaft for a high speed rotating machine has a diameter of 150 mm. The absolute pressure

within the machine is 2.5x10$Pa and the operating temperature is approximately 443 K. Design

a suitable labyrinth seal to limit the flow of air escaping from the machine to a chamber at an

absolute pressure of 2.2 bar to 0.03 kg/s.

12.6/ An axial bush seal consists of an annular gap with inner and outer radii of 0.025 and 0.0253mm,

pressures upstream and downstream of the seal are 6 and 5.5 bar, respectively. The viscosity

of the oil can be taken as 0.02 Pa s.

respectively. The length of the seal is 30mm. Determine the flow rate of oil through the seal if

the

12.7/ Determine the flow rate of air through an axial bush seal. The outer diameter of the inner

cylinder is 100 mm and the radial clearance is 0.1mm. The length of the seal is 50mm. The

pressures upstream and downstream of the seal are 1.4 and 1.01 bar, respectively. The viscosity

of air can be taken as 1.85×10-5Pa s.

12.8/ A radial bush seal consists of a cylinder with an inner radius of 20 mm and an outer radius of

40mm. The axial gap is 0.2mm. Determine the flow rate of oil through the clearance if the

pressure inside the cylinder is 6 bar and the pressure outside the cylinder is 5.2 bar. Take the

viscosity of oil as 0.022 Pa s.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY