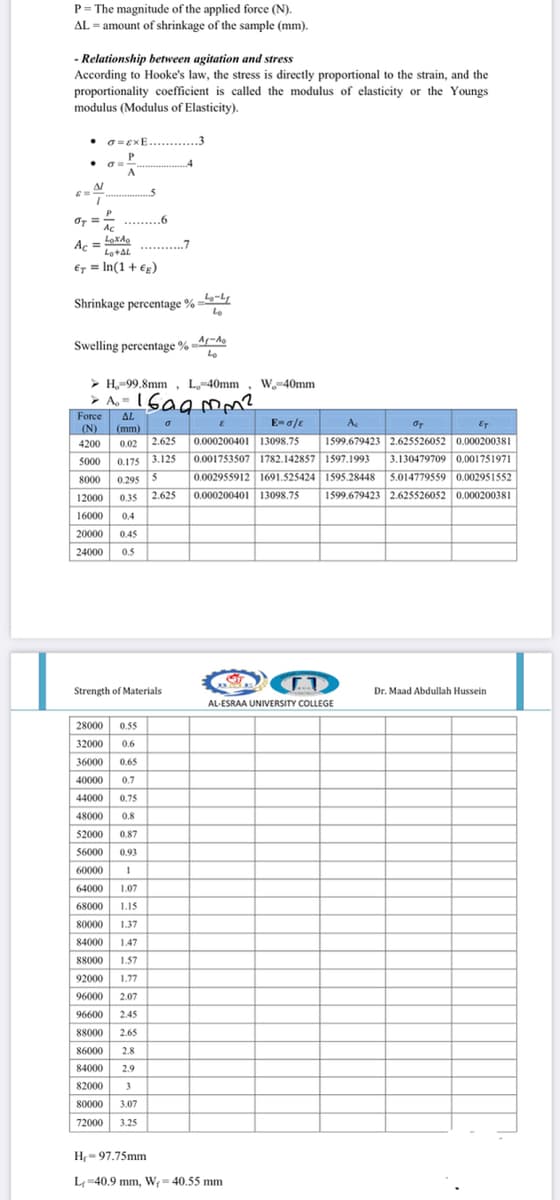

P= The magnitude of the applied force (N). AL = amount of shrinkage of the sample (mm). - Relationship between agitation and stress According to Hooke's law, the stress is directly proportional to the strain, and the proportionality coefficient is called the modulus of elasticity or the Youngs modulus (Modulus of Elasticity). • a=exE. P A AC Ac Lotal Er = In(1 + €g) Shrinkage percentage % --4 Swelling percentage % -Ad > H,-99.8mm, L,-40mm , W.-40mm Force (N) AL E-a/e A (mm) 2.625 1599.679423 2.625526052 0.000200381 3.130479709 0.001751971 5.014779559 0.002951552 4200 0.02 0.000200401 13098.75 0.001753507 1782.142857 1597.1993 0.002955912 1691.525424 1595.28448 5000 0.175 3.125 0.295 5 2.625 8000 12000 0.35 0.000200401 13098.75 1599.679423 2.625526052 0.000200381 16000 0.4 20000 0.45 24000 0.5

P= The magnitude of the applied force (N). AL = amount of shrinkage of the sample (mm). - Relationship between agitation and stress According to Hooke's law, the stress is directly proportional to the strain, and the proportionality coefficient is called the modulus of elasticity or the Youngs modulus (Modulus of Elasticity). • a=exE. P A AC Ac Lotal Er = In(1 + €g) Shrinkage percentage % --4 Swelling percentage % -Ad > H,-99.8mm, L,-40mm , W.-40mm Force (N) AL E-a/e A (mm) 2.625 1599.679423 2.625526052 0.000200381 3.130479709 0.001751971 5.014779559 0.002951552 4200 0.02 0.000200401 13098.75 0.001753507 1782.142857 1597.1993 0.002955912 1691.525424 1595.28448 5000 0.175 3.125 0.295 5 2.625 8000 12000 0.35 0.000200401 13098.75 1599.679423 2.625526052 0.000200381 16000 0.4 20000 0.45 24000 0.5

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Name of a report STRENGTH OF MATERIALS LABORATORY COMPRESSION TEST Hi sir, I know your precious time will be taken, please get a report. I want you to explain to me one or two pages is enough for me, dear sir, by solving the last schedule, may God help you and grant you God bless you

Transcribed Image Text:P= The magnitude of the applied force (N).

AL = amount of shrinkage of the sample (mm).

- Relationship between agitation and stress

According to Hooke's law, the stress is directly proportional to the strain, and the

proportionality coefficient is called the modulus of elasticity or the Youngs

modulus (Modulus of Elasticity).

•

O =ExE...........3

A

in

..6

......

Ac

LoxAo

Ac

Lo+AL

€r = In(1 + €e)

Shrinkage percentage % --L

Swelling percentage % -d

Lo

> H,-99.8mm , L,-40mm

> A.- 1Gagm?

W.-40mm

Force

AL

E-a/e

A

ET

(N)

(mm)

0.000200401 13098.75

0.001753507 1782.142857 1597.1993

0.002955912 1691.525424 1595.28448

1599.679423 2.625526052 0.000200381

3.130479709 0.001751971

4200

0.02

2.625

5000

0.175 3.125

8000

0.295 5

5.014779559 0.002951552

12000

0.35

2.625

0.000200401 13098.75

1599.679423 2.625526052 0.000200381

16000

0.4

20000 0.45

24000

0.5

Strength of Materials

Dr. Maad Abdullah Hussein

AL-ESRAA UNIVERSITY COLLEGE

28000 0.55

32000

0.6

36000

0.65

40000

0.7

44000

0.75

48000

0.8

52000

0.87

56000

0.93

60000

64000

1.07

68000

1.15

80000

1.37

84000

1.47

88000

1.57

92000

1.77

96000

2.07

96600

2.45

88000

2.65

86000

2.8

84000

2.9

82000

3

80000

3.07

72000

3.25

H- 97.75mm

L-40.9 mm, W- 40.55 mm

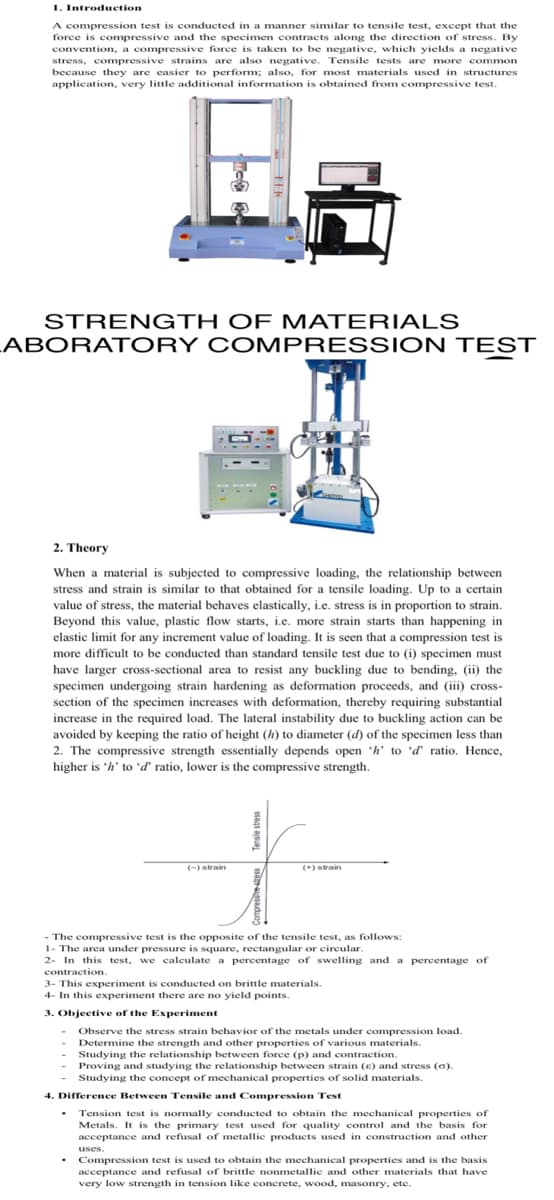

Transcribed Image Text:1. Introduction

A compression test is conducted in a manner similar to tensile test, except that the

force is compressive and the specimen contracts along the direction of stress. By

convention, a compressive force is taken to be negative, which yields a negative

stress, compressive strains are also negative. Tensile tests are more common

because they are easier to perform; also, for most materials used in structures

application, very little additional information is obtained from compressive test.

STRENGTH OF M ATERIALS

ABORAT ORY COMPRESSION TEST

2. Theory

When a material is subjected to compressive loading, the relationship between

stress and strain is similar to that obtained for a tensile loading. Up to a certain

value of stress, the material behaves elastically, i.e. stress is in proportion to strain.

Beyond this value, plastic flow starts, i.e. more strain starts than happening in

elastic limit for any increment value of loading. It is seen that a compression test is

more difficult to be conducted than standard tensile test due to (i) specimen must

have larger cross-sectional area to resist any buckling due to bending, (ii) the

specimen undergoing strain hardening as deformation proceeds, and (iii) cross-

section of the specimen increases with deformation, thereby requiring substantial

increase in the required load. The lateral instability due to buckling action can be

avoided by keeping the ratio of height (h) to diameter (d) of the specimen less than

2. The compressive strength essentially depends open h' to d' ratio. Hence,

higher is 'h' to 'd' ratio, lower is the compressive strength.

(-) strain

(*) strain

- The compressive test is the opposite of the tensile test, as follows:

1- The area under pressure is square, rectangular or eircular.

2- In this test, we calculate a percentage of swelling and a percentage of

contraction.

3- This experiment is conducted on brittle materials.

4- In this experiment there are no yield points.

3. Objective of the Experiment

Observe the stress strain behavior of the metals under compression load.

Determine the strength and other properties of various materials.

Studying the relationship between force (p) and contraction.

Proving and studying the relationship between strain (E) and stress (6).

Studying the concept of mechanical properties of solid materials.

4. Difference Between Tensile and Compression Test

Tension test is normally conducted to obtain the mechanical properties of

Metals. It is the primary test used for quality control and the basis for

acceptance and refusal of metallie products used in construction and other

uses.

Compression test is used to obtain the mechanical properties and is the basis

acceptance and refusal of brittle nonmetallic and other materials that have

very low strength in tension like concrete, wood, masonry, etc.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY