Questions 1. Why productivity had declined in Sakshi Garments Limited? 2. Who was responsible for the problem in the case? 3. Was the strategy adopted by the Vice President correct?

Questions 1. Why productivity had declined in Sakshi Garments Limited? 2. Who was responsible for the problem in the case? 3. Was the strategy adopted by the Vice President correct?

Chapter1: Taking Risks And Making Profits Within The Dynamic Business Environment

Section: Chapter Questions

Problem 1CE

Related questions

Question

Questions

1. Why productivity had declined in Sakshi Garments Limited?

2. Who was responsible for the problem in the case?

3. Was the strategy adopted by the Vice President correct?

4. Had you been in Ghosh's position, how would you have handled the situation?

5. Has the problem been resolved in the case? Comment.

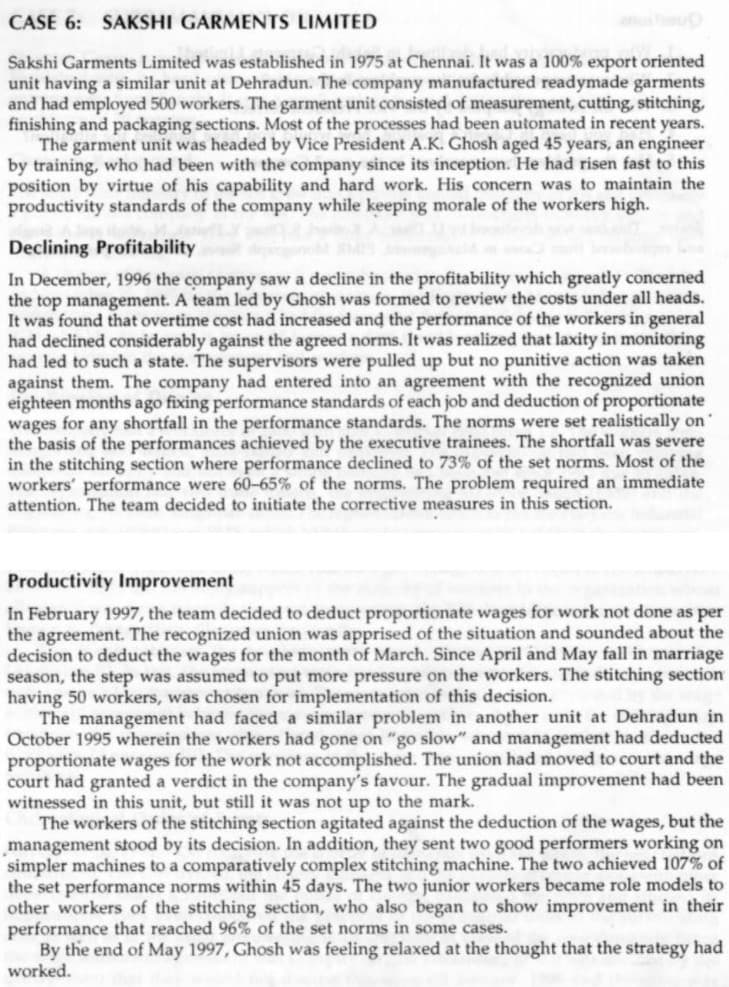

Transcribed Image Text:CASE 6: SAKSHI GARMENTS LIMITED

Sakshi Garments Limited was established in 1975 at Chennai. It was a 100% export oriented

unit having a similar unit at Dehradun. The company manufactured readymade garments

and had employed 500 workers. The garment unit consisted of measurement, cutting, stitching,

finishing and packaging sections. Most of the processes had been automated in recent years.

The garment unit was headed by Vice President A.K. Ghosh aged 45 years, an engineer

by training, who had been with the company since its inception. He had risen fast to this

position by virtue of his capability and hard work. His concern was to maintain the

productivity standards of the company while keeping morale of the workers high.

Declining Profitability

In December, 1996 the company saw a decline in the profitability which greatly concerned

the top management. A team led by Ghosh was formed to review the costs under all heads.

It was found that overtime cost had increased and the performance of the workers in general

had declined considerably against the agreed norms. It was realized that laxity in monitoring

had led to such a state. The supervisors were pulled up but no punitive action was taken

against them. The company had entered into an agreement with the recognized union

eighteen months ago fixing performance standards of each job and deduction of proportionate

wages for any shortfall in the performance standards. The norms were set realistically on

the basis of the performances achieved by the executive trainees. The shortfall was severe

in the stitching section where performance declined to 73%

workers' performance were 60-65% of the norms. The problem required an immediate

attention. The team decided to initiate the corrective measures in this section.

the set norms. Most of the

Productivity Improvement

In February 1997, the team decided to deduct proportionate wages for work not done as per

the agreement. The recognized union was apprised of the situation and sounded about the

decision to deduct the wages for the month of March. Since April and May fall in marriage

season, the step was assumed to put more pressure on the workers. The stitching section

having 50 workers, was chosen for implementation of this decision.

The management had faced a similar problem in another unit at Dehradun in

October 1995 wherein the workers had gone on "go slow" and management had deducted

proportionate wages for the work not accomplished. The union had moved to court and the

court had granted a verdict in the company's favour. The gradual improvement had been

witnessed in this unit, but still it was not up to the mark.

The workers of the stitching section agitated against the deduction of the wages, but the

management stood by its decision. In addition, they sent two good performers working on

simpler machines to a comparatively complex stitching machine. The two achieved 107% of

the set performance norms within 45 days. The two junior workers became role models to

other workers of the stitching section, who also began to show improvement in their

performance that reached 96% of the set norms in some cases.

By the end of May 1997, Ghosh was feeling relaxed at the thought that the strategy had

worked.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Recommended textbooks for you

Understanding Business

Management

ISBN:

9781259929434

Author:

William Nickels

Publisher:

McGraw-Hill Education

Management (14th Edition)

Management

ISBN:

9780134527604

Author:

Stephen P. Robbins, Mary A. Coulter

Publisher:

PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract…

Management

ISBN:

9781305947412

Author:

Cliff Ragsdale

Publisher:

Cengage Learning

Understanding Business

Management

ISBN:

9781259929434

Author:

William Nickels

Publisher:

McGraw-Hill Education

Management (14th Edition)

Management

ISBN:

9780134527604

Author:

Stephen P. Robbins, Mary A. Coulter

Publisher:

PEARSON

Spreadsheet Modeling & Decision Analysis: A Pract…

Management

ISBN:

9781305947412

Author:

Cliff Ragsdale

Publisher:

Cengage Learning

Management Information Systems: Managing The Digi…

Management

ISBN:

9780135191798

Author:

Kenneth C. Laudon, Jane P. Laudon

Publisher:

PEARSON

Business Essentials (12th Edition) (What's New in…

Management

ISBN:

9780134728391

Author:

Ronald J. Ebert, Ricky W. Griffin

Publisher:

PEARSON

Fundamentals of Management (10th Edition)

Management

ISBN:

9780134237473

Author:

Stephen P. Robbins, Mary A. Coulter, David A. De Cenzo

Publisher:

PEARSON