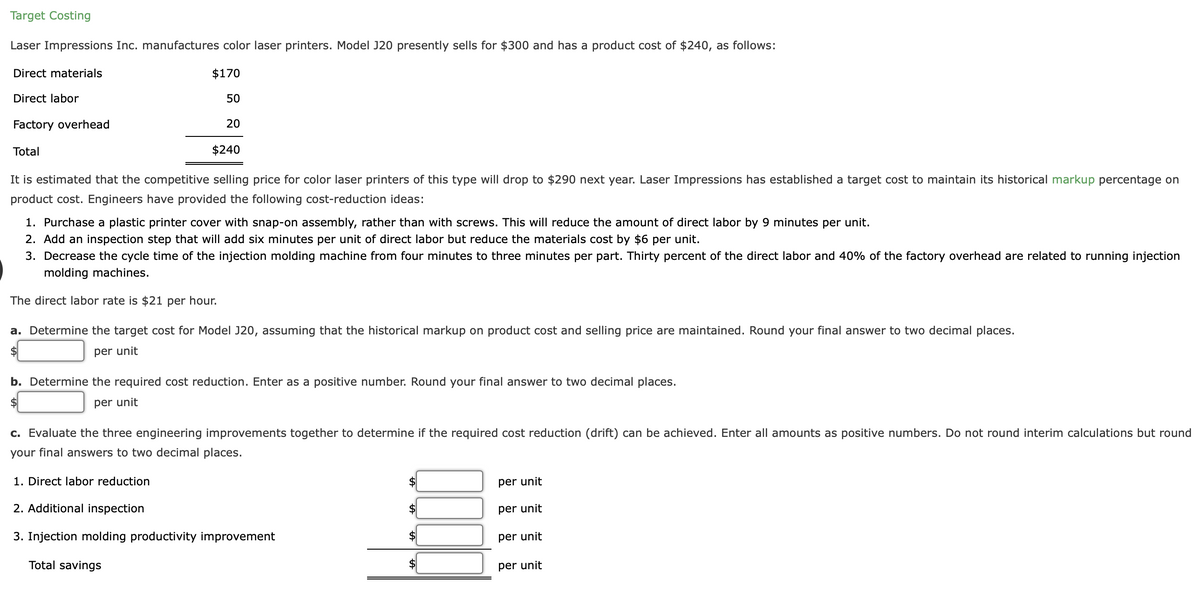

Target Costing Laser Impressions Inc. manufactures color laser printers. Model J20 presently sells for $300 and has a product cost of $240, as follows: Direct materials $170 Direct labor 50 Factory overhead 20 Total $240 It is estimated that the competitive selling price for color laser printers of this type will drop to $290 next year. Laser Impressions has established a target cost to maintain its historical markup percentage on product cost. Engineers have provided the following cost-reduction ideas: 1. Purchase a plastic printer cover with snap-on assembly, rather than with screws. This will reduce the amount of direct labor by 9 minutes per unit. 2. Add an inspection step that will add six minutes per unit of direct labor but reduce the materials cost by $6 per unit. 3. Decrease the cycle time of the injection molding machine from four minutes to three minutes per part. Thirty percent of the direct labor and 40% of the factory overhead are related to running injection molding machines. The direct labor rate is $21 per hour. a. Determine the target cost for Model J20, assuming that the historical markup on product cost and selling price are maintained. Round your final answer to two decimal places. per unit b. Determine the required cost reduction. Enter as a positive number. Round your final answer to two decimal places. per unit c. Evaluate the three engineering improvements together to determine if the required cost reduction (drift) can be achieved. Enter all amounts as positive numbers. Do not round interim calculations but round your final answers to two decimal places. 1. Direct labor reduction per unit 2. Additional inspection per unit 3. Injection molding productivity improvement per unit Total savings per unit

Target Costing Laser Impressions Inc. manufactures color laser printers. Model J20 presently sells for $300 and has a product cost of $240, as follows: Direct materials $170 Direct labor 50 Factory overhead 20 Total $240 It is estimated that the competitive selling price for color laser printers of this type will drop to $290 next year. Laser Impressions has established a target cost to maintain its historical markup percentage on product cost. Engineers have provided the following cost-reduction ideas: 1. Purchase a plastic printer cover with snap-on assembly, rather than with screws. This will reduce the amount of direct labor by 9 minutes per unit. 2. Add an inspection step that will add six minutes per unit of direct labor but reduce the materials cost by $6 per unit. 3. Decrease the cycle time of the injection molding machine from four minutes to three minutes per part. Thirty percent of the direct labor and 40% of the factory overhead are related to running injection molding machines. The direct labor rate is $21 per hour. a. Determine the target cost for Model J20, assuming that the historical markup on product cost and selling price are maintained. Round your final answer to two decimal places. per unit b. Determine the required cost reduction. Enter as a positive number. Round your final answer to two decimal places. per unit c. Evaluate the three engineering improvements together to determine if the required cost reduction (drift) can be achieved. Enter all amounts as positive numbers. Do not round interim calculations but round your final answers to two decimal places. 1. Direct labor reduction per unit 2. Additional inspection per unit 3. Injection molding productivity improvement per unit Total savings per unit

Managerial Accounting

15th Edition

ISBN:9781337912020

Author:Carl Warren, Ph.d. Cma William B. Tayler

Publisher:Carl Warren, Ph.d. Cma William B. Tayler

Chapter11: Differential Analysis And Product Pricing

Section: Chapter Questions

Problem 19E

Related questions

Question

100%

Diff Analysis & Product Pricing:

Transcribed Image Text:Target Costing

Laser Impressions Inc. manufactures color laser printers. Model J20 presently sells for $300 and has a product cost of $240, as follows:

Direct materials

$170

Direct labor

50

Factory overhead

20

Total

$240

It is estimated that the competitive selling price for color laser printers of this type will drop to $290 next year. Laser Impressions has established a target cost to maintain its historical markup percentage on

product cost. Engineers have provided the following cost-reduction ideas:

1. Purchase a plastic printer cover with snap-on assembly, rather than with screws. This will reduce the amount of direct labor by 9 minutes per unit.

2. Add an inspection step that will add six minutes per unit of direct labor but reduce the materials cost by $6 per unit.

3. Decrease the cycle time of the injection molding machine from four minutes to three minutes per part. Thirty percent of the direct labor and 40% of the factory overhead are related to running injection

molding machines.

The direct labor rate is $21 per hour.

a. Determine the target cost for Model J20, assuming that the historical markup on product cost and selling price are maintained. Round your final answer to two decimal places.

$

per unit

b. Determine the required cost reduction. Enter as a positive number. Round your final answer to two decimal places.

$4

per unit

c. Evaluate the three engineering improvements together to determine if the required cost reduction (drift) can be achieved. Enter all amounts as positive numbers. Do not round interim calculations but round

your final answers to two decimal places.

1. Direct labor reduction

per unit

2. Additional inspection

$

per unit

3. Injection molding productivity improvement

$4

per unit

Total savings

$

per unit

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 4 steps

Recommended textbooks for you

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Principles of Accounting Volume 2

Accounting

ISBN:

9781947172609

Author:

OpenStax

Publisher:

OpenStax College

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning