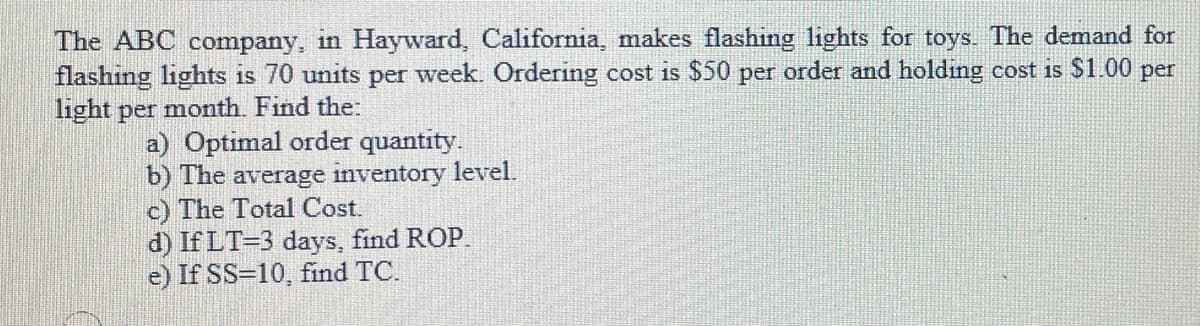

The ABC company, in Hayward, California, makes flashing lights for toys. The demand for flashing lights is 70 units per week. Ordering cost is $50 per order and holding cost is $1.00 per light per month. Find the: a) Optimal order quantity. b) The average inventory level. c) The Total Cost. d) If LT=3 days, find ROP. e) If SS=10, find TC.

Q: hat are some generic business strategies of family firms, and on what family-firm-specific…

A: The quintessence of a family firm is believed to be a component of a family's effect on the way of…

Q: Optimal Prime is leading its group of AMPLbots into battle against Gigatron and the Deceivacons,…

A: Find the Given details below: Given details: A B C D E Capacity Unit cost 1 15 20 10…

Q: How much profit would she make at the optimum combination of resources?

A: Linear programming is a mathematical technique that is also used in operations management…

Q: s advise a project manager of a lanning process

A: Construction planning is an essential and testing action in the administration and execution of…

Q: Discuss five (5) challenges in setting goals

A: Organizations like Summerwood Hotel today are focused upon delivering the best commodities to their…

Q: er its existence? What are the main operations performance objectives for McDon

A: The whole McDonald's procedure is so laborious that it takes less than 5 minutes from the time you…

Q: Based on the following sequential decision tree, compute the expected payoff of node 7. It is (type…

A: A decision tree is the analysis of the options that are to be considered or chosen among to take the…

Q: Activity Greet customer Take order Process order Print receipt Activity Time per Customer 5 seconds…

A: Given data Demand rate = 20 customer per hour

Q: The following reflects the types of processes aligned with the process analysis method: a.…

A: Explanation: Method analysis in the context of ergonomics is a technique for assessing the…

Q: 1. When is the best time to do the cycle count? and give examples of cycle count methodologies.

A: The cycle count method provides the correct amount of stock available in the warehouse. This method…

Q: nswer. Level output/workforce strategy: Monthly planning for all the products in same family…

A: The term "aggregate planning" is used to describe the process of developing, updating, and…

Q: At the Strathmore University Cafeteria, students seeking to have a meal are observed to arrive at a…

A: Arrival rate λ 16 per 20 min Service rate µ 19 per 20 min

Q: CASE 2. “The Possibility"Restaurant Angela Fox and Zooey Caulfield were food and nutrition majors at…

A: Objective Functions and Constraints: Based on the given details, the objective…

Q: What systems are in-place to prevent stock-outs?

A: Stock out: Stock out situation is very dangerous to every business and it directly…

Q: Required: Find the maximum value for profits and the number of materials produced from televisions…

A: Linear programming is a mathematical technique that is also used in operations management…

Q: An automatic lathe produces rollers for roller bearings, and the process is monitored by statistical…

A: Given data N= 4 The central line with respect to the sample means is fixed at 8.60 and mean range…

Q: Describe the factors that should be considered in establishing a maintenance programme in an…

A: An organization needs to establish a maintenance program as it gives rise to high productivity which…

Q: standard mix of Peanut/Raisin Delite to put up. The deluxe mix has .68 pounds of raisins and .32…

A: Deluxe Standard Cost per pound Raisins (pounds) 0.68 0.5 $ 1.50 Peanuts (pounds) 0.32…

Q: (a) Use the Northwest-Corner Method, the Least-Cost Method and the VAM to get the starting feasible…

A: The transportation model is used to calculate the minimum cost of the route by selecting different…

Q: offer for S1 only; or offer for S2 only; or offer for both S1 and S2. If offers are to be submitted,…

A: Given: Option Possible offer Prices(Euro) Probability of getting contract S1 only 130000…

Q: A manufacturer produces lots of a canned food product. Let p denote the proportion of the lots that…

A: Since, the (a) and (b) part has already been correctly solved, I have solved the (c) part in the…

Q: A small firm intends to increase the capacity of a bottleneck operation by adding a new machine. Two…

A:

Q: NSTRUCTIONS: Draw the AON network for Exercise 14 (pg ASSIGNMENT 200 & 201). Complete the forward…

A: A network diagram is a visual representation of a project which helps to identify the activity…

Q: a) what is the maximax decision? b) what is the maximin decision c) what is the equally likely…

A: Mathematic models of decision-making help businesses take the correct decision for their operational…

Q: Rosaliz has been working for ten years in a food and institutional product distribution company that…

A: Operations management is a management area where the designing and controlling part of the…

Q: What is the difference between a list of inventory items and their quantities on hand and a physical…

A: Here, I would differentiate between the list of inventory items and their quantities on hand and a…

Q: By using and making reference to the case information attached - Explain any 4 reasons for global…

A: The given case is about the challenges faced by company H. The company is facing the issue of…

Q: You have been made the purchasing manager of a local restaurant. This restaurant is part of a chain…

A: A restaurant is a business in the service industry. A service cannot be stored, so it is initiated…

Q: For the Orlando real estate investment problem, assume the probabilities for the gasoline shortage,…

A: Given data is

Q: Which of the following is a disadvantage of partnership? Question 5 options: Unlimited…

A: A partnership is nothing but the form of business where two or more two individuals or firms share…

Q: discuss the 8 principles of a Quality Management Systems, utilising practical examples for each…

A: Quality management principles are based on a group of essential beliefs, standards, rules, &…

Q: Consider the following three-station production line with a single product that must visit stations…

A: Given data

Q: ties: Simple moving average, Weighted moving average, Simple Exponential Smoothing,…

A: Forecasting demand is one of the most important things in the supply chain. It helps companies plan…

Q: An airline operates a call center to handle customer questions and complaints. The airline monitors…

A: As per Bartleby's guidelines, I have solved the first three sub-parts of the given question. Kindly…

Q: Discuss five benefits that come from using the principles that are applied in Network Logistics by…

A: Logistics directs the all-around process of controlling how resources are received, stored, &…

Q: By using the case information attached - Outline each of the 4 aspects (Integration, Operations,…

A: In the dynamic market of fashion, it is important to be adaptable to the changes and to be proactive…

Q: ntries on a 24/7 basis. Often these executives do not have a deep cultural or social understanding…

A: Communication is fundamental for navigation and arranging. It empowers the administration to get…

Q: 1. A furniture company manufactures two products, P1 and P2, through a two-fold operation: automatic…

A:

Q: 4. An industrial engineer has conducted a study aiming to minimize traffic flow between the work…

A:

Q: Fabricators, Inc. wants to increase capacity by adding a new machine. The fixed costs for machine A…

A: Breakeven Point is that level of sales at which there is no profit no loss. In other words at…

Q: Foreign vendors are added to a company's supply chain for a variety of reasons. However, the…

A: A company will evaluate various suppliers and finally hire the one for whom they feel that their…

Q: Which of the following is a critical path? O2->5->8 1->4->8 O 1->3->7 O 1->3->6->8

A: A project schedule network diagram shows the sequence of the task that is performed to complete a…

Q: Discuss the concept of supply alliance in e-commerce

A: E-commerce (electronic commerce, e-business) is conducted over computer networks, including the…

Q: B/ solve the following linear programming problem using graphical method Min (z) = 300x₁+200x2 S.T.…

A: A graphical method of linear programming is used to find an optimal solution to a linear program.…

Q: Discuss how Walmart's Cambridge Foods will determine which supplier is capable of meeting its needs

A: A supplier assessment is the process of evaluating & approving prospective vendors through…

Q: Using trend-adjusted exponential smoothing, Forecasts (F₂), Trend (T₂), and Forecasts Including…

A: Forecasting is a technique used to predict future outcomes on the basis of past data. In businesses…

Q: HELP

A:

Q: (1) Use the least cost method to find an initial feasible solution (5%)

A:

Q: 16. Backward integration is achieved through a. A coalition of the firm's suppliers. b. The purchase…

A: Backward integration generally occurs when the organization wishes to obtain a complete control over…

Q: What is Keynesian Economics and why is it important?

A: Keynesian economics is a macroeconomic economic theory that describes overall economic expenditure…

Step by step

Solved in 2 steps

- Saga ltd. produces electronic toys for children between the ages of 7-10 years old. The toys use a processor that is imported from Japan. Annual demand for the processor is 12,500. The holding cost per processor per year is $2. Ordering cost per order is $400. Lead time is 7 days and the number of working days in the year is 250. a. What is the economic order quantity? b. What is the optimal number of orders per year? c. Calculate the annual holding cost if the economic order quantity is used. d. What is the optimal number of days between any two orders? e. What is the reorder point? f. Given the EOQ, what is the total annual inventory cost?Design your own inventory management problem with the required input data and answer the following questions : a. What is the optimal order size? b. What is the optimal number of orders per year? What is the optimal number of days between orders? d. What is the annual inventory cost? e. If the lead time were X days/weeks/months, what would be the reorder point? f. For what value of ordering cost would Y units of order size be optimal?Rafiki Bar uses 10,000 cases of millet beer monthly. One case costs Shs.5,000. Holding cost is 30% of the cost of a case p.a while ordering cost is Shs.100,000 per order. The firm works 360 days in a year while lead time is 6 days. Required: ii. Determine the days between orders and the reorder point iii. Determine the total cost of the inventory policy iv. Suppose actual holding cost turns out to be 15% instead of 30% and the inventory policy above is implemented for a year, determine the cost of prediction error if every other parameter estimate turns out as predicted.

- Matthew Liotine’s Dream Store sells beds andassorted supplies. His best-selling bed has an annual demandof 400 units. Ordering cost is $40; holding cost is $5 per unitper year.a) To minimize the total cost, how many units should beordered each time an order is placed?b) If the holding cost per unit was $6 instead of $5, whatwould be the optimal order quantity?The annual demand of Maize Meal = 750 units (bigger size), Delivered purchase cost = R35/units, Annual carrying cost percentage= 25 percent, Order cost = R50/order. The lead time is 10 working days. Assuming 20 working days per month.1 Determine the Economic Order Quantity 2 Determine the reorder point 3 Determine the average inventory 4 Suppose orders are placed only at review time. Find the optimal period and the optimal order quantity.An organization manufactures supplies for landscaping companies which has an annual demand of 16,000. The cost of storing each unit is $2.5/year and $50 to make an order. Say the company has 300 days of annually, answer the following questions: a. What is the optimal order quantity? b. How many orders in a year? c. How many days between orders? d. How much is the total inventory cost?

- Custom Computers, Inc. assembles custom home computersystems. Th e heat sinks needed are bought for $12 each and areordered in quantities of 1300 units. Annual demand is 5200 heatsinks, the annual inventory holding cost rate is $3 per unit, andthe cost to place an order is estimated to be $50. Calculate thefollowing:(a) Average inventory level(b) Th e number of orders placed per year(c) Th e total annual inventory holding cost(d) Th e total annual ordering cost(e) Th e total annual costDo all work in Excel with Formulas An office supply store open 5 days a week must determine the best inventory policy for boxes of copier paper. Weekly demand is nearly constant at 250 boxes and when orders are placed, then entire shipment arrives at once. The cost per box is $22 and the inventory holding cost is 30%. Orders are placed at a cost of $40 each, including preparation time and communication charges, and the lead time is 2 days. a. Find the optimal order quantity. b. What is the reorder point? c. How often should an order be placed? d. What is the cycle time?Saga ltd. produces electronic toys for children between the ages of 7-10 years old. The toys use a processor that is imported from Japan. Annual demand for the processor is 12,500. The holding cost per processor per year is $2. Ordering cost per order is $400. Lead time is 7 days and the number of working days in the year is 250. d. What is the optimal number of days between any two orders? e. What is the reorder point? f. Given the EOQ, what is the total annual inventory cost?

- The annual demand of Maize Meal = 750 units (bigger size), Delivered purchase cost = R35/units, Annual carryingcost percentage= 25 percent, Order cost = R50/order. The lead time is 10 working days. Assuming 20 working days per month.Determine the Economic Order Quantity. Determine the reorder point .Determine the average inventory .Suppose orders are placed only at review time. Find the optimal period and the optimal order quantity.answer in 30 minutes. The seasonal demand for a particular product is given below: Period 1 2 3 4 5 6 Demand 300 450 100 450 450 100 The fixed parameters are: Fixed Cost $8 Unit Production Cost $1 Holding Cost $1.3 Calculate total ordering cost using following three methods: i) Lot-for-Lot ii) Wagner-Whitin algorithm iii) Fixed order quantityBanana Inc. a Company that markets skin care products . The annual demond is 2400 units and ordering cost is 10 per order . The holding cost per year is 0.30 .Amount of the working days of the is 250 days in a year , Lead time of the order is 2 days . a. What is the optimal order size? b. What is the optimal number of orders per year? c. What is the optimal number of days between orders? d. What is the annual inventory cost? e. If the lead time were 2 days, what would be the reorder point? f. For what value of ordering cost would 1000 units of order size be optimal? g. Determine how often the firm should order. h. Determine the size of each order ı. At what price should the firm order?