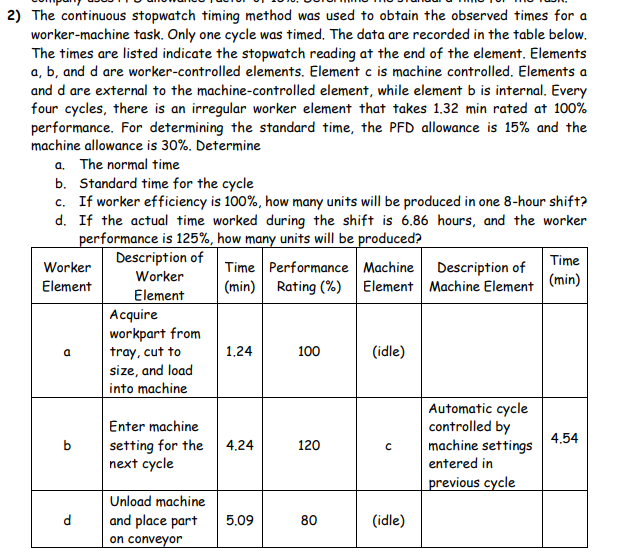

) The continuous stopwatch timing method was used to obtain the observed times for a worker-machine task. Only one cycle was timed. The data are recorded in the table below. The times are listed indicate the stopwatch reading at the end of the element. Elements a, b, and d are worker-controlled elements. Element c is machine controlled. Elements a and d are external to the machine-controlled element, while element b is internal. Every four cycles, there is an irregular worker element that takes 1.32 min rated at 100% performance. For determining the standard time, the PFD allowance is 15% and the machine allowance is 30%. Determine a. The normal time b. Standard time for the cycle c. If worker efficiency is 100%, how many units will be produced in one 8-hour shift? d. If the actual time worked during the shift is 6.86 hours, and the worker performance is 125%, how many units will be produced? Description of Time Worker Time Performance Machine Description of Worker Element (min) Rating (%) Element Machine Element (min) Element Acquire workpart from tray, cut to size, and load into machine 1.24 100 (idle) Automatic cycle controlled by machine settings entered in Enter machine 4.54 setting for the next cycle b 4,24 120 previous cycle Unload machine d (idle) and place part on conveyor 5,09 80

) The continuous stopwatch timing method was used to obtain the observed times for a worker-machine task. Only one cycle was timed. The data are recorded in the table below. The times are listed indicate the stopwatch reading at the end of the element. Elements a, b, and d are worker-controlled elements. Element c is machine controlled. Elements a and d are external to the machine-controlled element, while element b is internal. Every four cycles, there is an irregular worker element that takes 1.32 min rated at 100% performance. For determining the standard time, the PFD allowance is 15% and the machine allowance is 30%. Determine a. The normal time b. Standard time for the cycle c. If worker efficiency is 100%, how many units will be produced in one 8-hour shift? d. If the actual time worked during the shift is 6.86 hours, and the worker performance is 125%, how many units will be produced? Description of Time Worker Time Performance Machine Description of Worker Element (min) Rating (%) Element Machine Element (min) Element Acquire workpart from tray, cut to size, and load into machine 1.24 100 (idle) Automatic cycle controlled by machine settings entered in Enter machine 4.54 setting for the next cycle b 4,24 120 previous cycle Unload machine d (idle) and place part on conveyor 5,09 80

Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Chapter8: Computer Numerical Control

Section8.6: Cnc Milling: Programming

Problem 8RQ: Briefly describe the use of I and J for the arc center method of circular interpolation.

Related questions

Question

Transcribed Image Text:2) The continuous stopwatch timing method was used to obtain the observed times for a

worker-machine task. Only one cycle was timed. The data are recorded in the table below.

The times are listed indicate the stopwatch reading at the end of the element. Elements

a, b, and d are worker-controlled elements. Element c is machine controlled. Elements a

and d are external to the machine-controlled element, while element b is internal. Every

four cycles, there is an irregular worker element that takes 1.32 min rated at 100%

performance. For determining the standard time, the PFD allowance is 15% and the

machine allowance is 30%. Determine

a. The normal time

b. Standard time for the cycle

c. If worker efficiency is 100%, how many units will be produced in one 8-hour shift?

d. If the actual time worked during the shift is 6.86 hours, and the worker

performance is 125%, how many units will be produced?

Description of

Worker

Time

Description of

(min) Rating (%) Element Machine Element

Worker

Time Performance Machine

Element

(min)

Element

Acquire

workpart from

tray, cut to

size, and load

into machine

1.24

100

(idle)

a

Automatic cycle

controlled by

machine settings

entered in

Enter machine

4.54

setting for the

next cycle

b

4.24

120

previous cycle

Unload machine

and place part

on conveyor

d

5.09

80

(idle)

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Precision Machining Technology (MindTap Course Li…

Mechanical Engineering

ISBN:

9781285444543

Author:

Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning