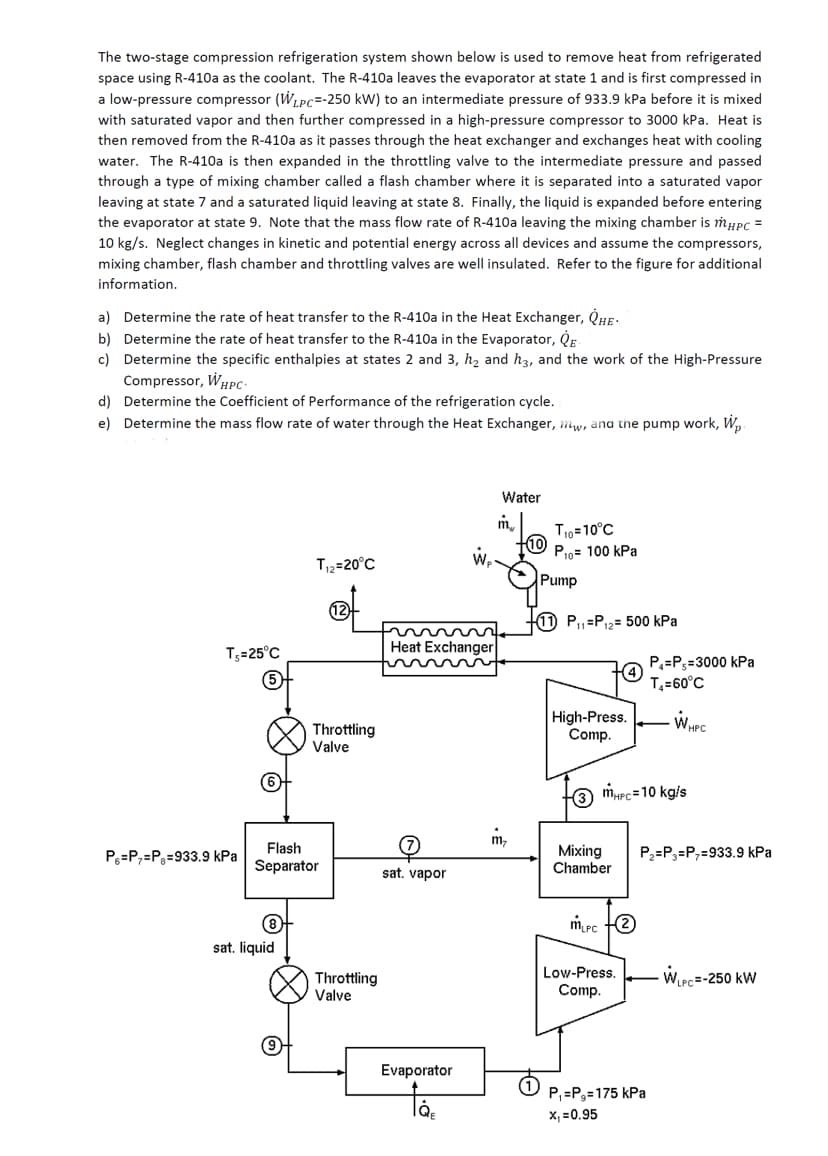

The two-stage compression refrigeration system shown below is used to remove heat from refrigerated space using R-410a as the coolant. The R-410a leaves the evaporator at state 1 and is first compressed in a low-pressure compressor (WLPC=-250 kW) to an intermediate pressure of 933.9 kPa before it is mixed with saturated vapor and then further compressed in a high-pressure compressor to 3000 kPa. Heat is then removed from the R-410a as it passes through the heat exchanger and exchanges heat with cooling water. The R-410a is then expanded in the throttling valve to the intermediate pressure and passed through a type of mixing chamber called a flash chamber where it is separated into a saturated vapor leaving at state 7 and a saturated liquid leaving at state 8. Finally, the liquid is expanded before entering the evaporator at state 9. Note that the mass flow rate of R-410a leaving the mixing chamber is ṁµPC = 10 kg/s. Neglect changes in kinetic and potential energy across all devices and assume the compressors, mixing chamber, flash chamber and throttling valves are well insulated. Refer to the figure for additional information. a) Determine the rate of heat transfer to the R-410a in the Heat Exchanger, QHE- b) Determine the rate of heat transfer to the R-410a in the Evaporator, QE c) Determine the specific enthalpies at states 2 and 3, h, and h3, and the work of the High-Pressure Compressor, WHPC- d) Determine the Coefficient of Performance of the refrigeration cycle. e) Determine the mass flow rate of water through the Heat Exchanger, mw, ana the pump work, W, Water m, T10=10°C W Po= 100 kPa w, T12=20°C Pump P,=P12= 500 kPa T;=25°C Heat Exchanger P,=P3=3000 kPa T=60°C Throttling Valve High-Press. Comp. O mPc=10 kg/s Flash Pe=P,=P=933.9 kPa Mixing Chamber P=P,=P,=933.9 kPa Separator sat. vapor sat. liquid Low-Press. Throttling Valve Wpc=-250 kW Comp. Evaporator to P,=P3=175 kPa X, =0.95

The two-stage compression refrigeration system shown below is used to remove heat from refrigerated space using R-410a as the coolant. The R-410a leaves the evaporator at state 1 and is first compressed in a low-pressure compressor (WLPC=-250 kW) to an intermediate pressure of 933.9 kPa before it is mixed with saturated vapor and then further compressed in a high-pressure compressor to 3000 kPa. Heat is then removed from the R-410a as it passes through the heat exchanger and exchanges heat with cooling water. The R-410a is then expanded in the throttling valve to the intermediate pressure and passed through a type of mixing chamber called a flash chamber where it is separated into a saturated vapor leaving at state 7 and a saturated liquid leaving at state 8. Finally, the liquid is expanded before entering the evaporator at state 9. Note that the mass flow rate of R-410a leaving the mixing chamber is ṁµPC = 10 kg/s. Neglect changes in kinetic and potential energy across all devices and assume the compressors, mixing chamber, flash chamber and throttling valves are well insulated. Refer to the figure for additional information. a) Determine the rate of heat transfer to the R-410a in the Heat Exchanger, QHE- b) Determine the rate of heat transfer to the R-410a in the Evaporator, QE c) Determine the specific enthalpies at states 2 and 3, h, and h3, and the work of the High-Pressure Compressor, WHPC- d) Determine the Coefficient of Performance of the refrigeration cycle. e) Determine the mass flow rate of water through the Heat Exchanger, mw, ana the pump work, W, Water m, T10=10°C W Po= 100 kPa w, T12=20°C Pump P,=P12= 500 kPa T;=25°C Heat Exchanger P,=P3=3000 kPa T=60°C Throttling Valve High-Press. Comp. O mPc=10 kg/s Flash Pe=P,=P=933.9 kPa Mixing Chamber P=P,=P,=933.9 kPa Separator sat. vapor sat. liquid Low-Press. Throttling Valve Wpc=-250 kW Comp. Evaporator to P,=P3=175 kPa X, =0.95

Refrigeration and Air Conditioning Technology (MindTap Course List)

8th Edition

ISBN:9781305578296

Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Chapter44: Geothermal Heat Pumps

Section: Chapter Questions

Problem 1RQ: Geothermal heat pumps, or water-source heat pumps, are classified as either _____loop or _____loop...

Related questions

Question

Transcribed Image Text:The two-stage compression refrigeration system shown below is used to remove heat from refrigerated

space using R-410a as the coolant. The R-410a leaves the evaporator at state 1 and is first compressed in

a low-pressure compressor (W, Pc=-250 kW) to an intermediate pressure of 933.9 kPa before it is mixed

with saturated vapor and then further compressed in a high-pressure compressor to 3000 kPa. Heat is

then removed from the R-410a as it passes through the heat exchanger and exchanges heat with cooling

water. The R-410a is then expanded in the throttling valve to the intermediate pressure and passed

through a type of mixing chamber called a flash chamber where it is separated into a saturated vapor

leaving at state 7 and a saturated liquid leaving at state 8. Finally, the liquid is expanded before entering

the evaporator at state 9. Note that the mass flow rate of R-410a leaving the mixing chamber is mypC =

10 kg/s. Neglect changes in kinetic and potential energy across all devices and assume the compressors,

mixing chamber, flash chamber and throttling valves are well insulated. Refer to the figure for additional

information.

a) Determine the rate of heat transfer to the R-410a in the Heat Exchanger, QHE-

b) Determine the rate of heat transfer to the R-410a in the Evaporator, QE

c) Determine the specific enthalpies at states 2 and 3, h, and h3, and the work of the High-Pressure

Compressor, Whpc-

d) Determine the Coefficient of Performance of the refrigeration cycle.

e) Determine the mass flow rate of water through the Heat Exchanger, mw, and the pump work, Wp

Water

m.

T10=10°C

10

w,

P10= 100 kPa

T12=20°C

Pump

12

1 P,=P12= 500 kPa

T3=25°C

Heat Exchanger

P=P3=3000 kPa

T=60°C

Throttling

Valve

High-Press.

Comp.

3 MHPC=10 kg/s

m,

Flash

Mixing

Chamber

P3=P;=Pg=933.9 kPa

P2=P3=P,=933.9 kPa

Separator

sat. vapor

mrc e

sat. liquid

Throttling

Valve

Low-Press.

Comp.

WPc=-250 kW

Evaporator

P, =P3=175 kPa

X, =0.95

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps with 2 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning

Refrigeration and Air Conditioning Technology (Mi…

Mechanical Engineering

ISBN:

9781305578296

Author:

John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:

Cengage Learning