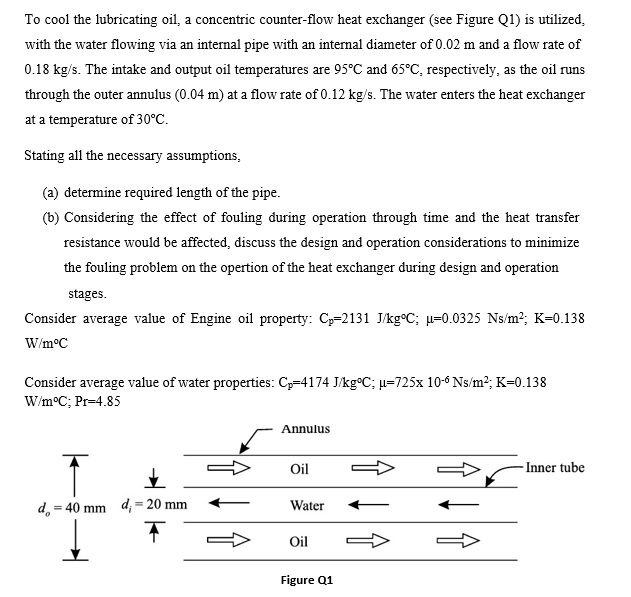

To cool the lubricating oil, a concentric counter-flow heat exchanger (see Figure Q1) is utilized, with the water flowing via an internal pipe with an internal diameter of 0.02 m and a flow rate of 0.18 kg/s. The intake and output oil temperatures are 95°C and 65°C, respectively, as the oil runs through the outer annulus (0.04 m) at a flow rate of 0.12 kg/s. The water enters the heat exchanger at a temperature of 30°C.

To cool the lubricating oil, a concentric counter-flow heat exchanger (see Figure Q1) is utilized, with the water flowing via an internal pipe with an internal diameter of 0.02 m and a flow rate of 0.18 kg/s. The intake and output oil temperatures are 95°C and 65°C, respectively, as the oil runs through the outer annulus (0.04 m) at a flow rate of 0.12 kg/s. The water enters the heat exchanger at a temperature of 30°C.

Principles of Heat Transfer (Activate Learning with these NEW titles from Engineering!)

8th Edition

ISBN:9781305387102

Author:Kreith, Frank; Manglik, Raj M.

Publisher:Kreith, Frank; Manglik, Raj M.

Chapter10: Heat Exchangers

Section: Chapter Questions

Problem 10.46P

Related questions

Question

Please help me .. answer my Question , I don't want to quote or plagiarize, don't use your handwriting just use MS Word .

Transcribed Image Text:To cool the lubricating oil, a concentric counter-flow heat exchanger (see Figure Q1) is utilized,

with the water flowing via an internal pipe with an internal diameter of 0.02 m and a flow rate of

0.18 kg/s. The intake and output oil temperatures are 95°C and 65°C, respectively, as the oil runs

through the outer annulus (0.04 m) at a flow rate of 0.12 kg/s. The water enters the heat exchanger

at a temperature of 30°C.

Stating all the necessary assumptions,

(a) determine required length of the pipe.

(b) Considering the effect of fouling đuring operation through time and the heat transfer

resistance would be affected, discuss the design and operation considerations to minimize

the fouling problem on the opertion of the heat exchanger during design and operation

stages.

Consider average value of Engine oil property: C-2131 JM/kg°C; µ=0.0325 Ns/m?; K=0.138

W/m°C

Consider average value of water properties: C-4174 J/kg°C; µ=725x 10-6 Ns/m?; K=0.138

W/m°C; Pr=4.85

Annulus

Oil

Inner tube

d = 40 mm d, = 20 mm

Water

Oil

Figure Q1

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning

Principles of Heat Transfer (Activate Learning wi…

Mechanical Engineering

ISBN:

9781305387102

Author:

Kreith, Frank; Manglik, Raj M.

Publisher:

Cengage Learning