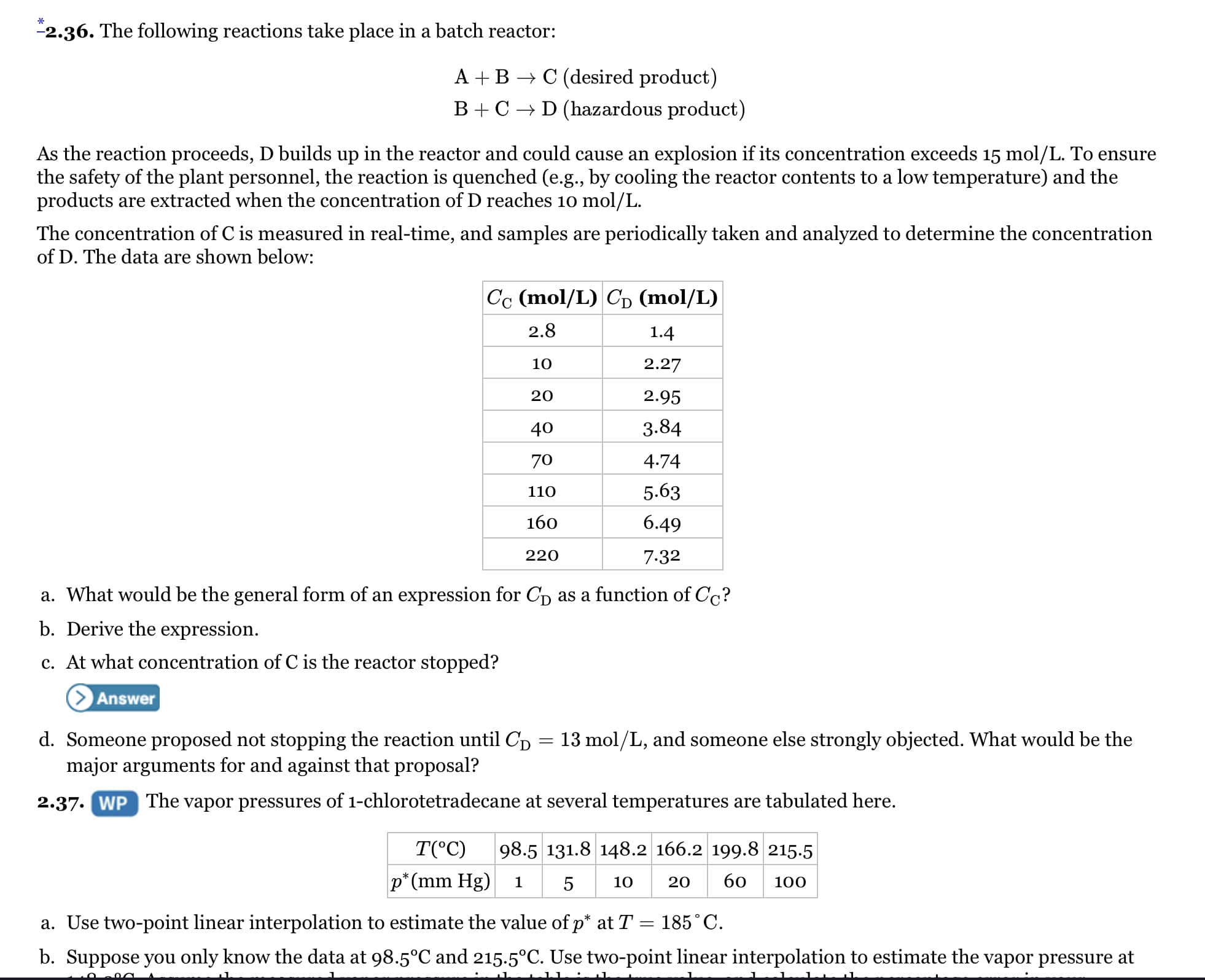

2.35. WP Bacteria can serve as catalysts for the conversion of low-cost chemicals, such as glucose, into higher value compounds, including commodity chemicals (with large production rates) and high-value specialty chemicals such as pharmaceuticals, dyes, and cosmetics. Commodity chemicals are produced from bacteria in very large bioreactors. For example, cultures up to 130,000 gallons are used to produce antibiotics and other therapeutics, industrial enzymes, and polymer intermediates. When a healthy bacteria culture is placed in a suitable environment with abundant nutrients, the bacteria experience balanced growth, meaning that they continue to double in number in the same fixed period of time. The doubling time of mesophilic bacteria (bacteria that live comfortably at temperatures between 35°C and 40°C) ranges anywhere from 20 minutes to a few hours. During balanced growth, the rate of growth of the bacteria is given by the expression dC dt where C(g/L) is the concentration of bacteria in the culture and u is called the specific growth rate of the bacteria (also described in Problem 2.33). The balanced growth phase eventually comes to an end, due either to the presence of a toxic byproduct or the lack of a key nutrient. The following data were measured for the growth of a particular species of mesophilic bacteria at a constant temperature: t(h) 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 C(g/L) 0.008 0.021 0.030 0.068 0.150 0.240 0.560 1.10 a. If bacteria are used in the production of a commodity chemical, would a low or high value of u be desirable? Explain. b. In the rate expression, separate the variables and integrate to derive an expression of the form f(C, Co) = µt, where C, is the bacteria concentration that would be measured at t = 0 if balanced growth extended back that far. (It might not.) What would you plot versus what on what kind of coordinates (rectangular, semilog, or log) to get a straight line if growth is balanced, and how would you determine u and C, from the plot? (Review Section 2.7 if necessary.) c. From the given data, determine whether balanced growth was maintained between t specific growth rate. (Give both its numerical value and its units.) 1h and t 8 h. If it was, calculate the d. Derive an expression for the doubling time of a bacterial species in balanced growth in terms of µ. [You may make use of your calculations in Part (b).] Calculate the doubling time of the species for which the data are given. SAFETY -2.36. The following reactions take place in a batch reactor: A +B → C (desired product) B+ C → D (hazardous product) As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the products are extracted when the concentration of D reaches 10 mol/L. The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration of D. The data are shown below: "2.36. The following reactions take place in a batch reactor: A +B → C (desired product) B+ C → D (hazardous product) As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the products are extracted when the concentration of D reaches 10 mol/L. The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration of D. The data are shown below: Cc (mol/L) Cp (mol/L) 2.8 1.4 10 2.27 20 2.95 40 3.84 70 4.74 110 5.63 160 6.49 220 7.32 a. What would be the general form of an expression for Cp as a function of Cc? b. Derive the expression. c. At what concentration of C is the reactor stopped? Answer d. Someone proposed not stopping the reaction until Cp = 13 mol/L, and someone else strongly objected. What would be the major arguments for and against that proposal? 2.37. WP The vapor pressures of 1-chlorotetradecane at several temperatures are tabulated here. T(°C) 98.5 131.8 148.2 166.2 199.8 215.5 p* (mm Hg) 5 10 20 60 100 a. Use two-point linear interpolation to estimate the value of p* at T = 185°C. b. Suppose you only know the data at 98.5°C and 215.5°C. Use two-point linear interpolation to estimate the vapor pressure at

2.35. WP Bacteria can serve as catalysts for the conversion of low-cost chemicals, such as glucose, into higher value compounds, including commodity chemicals (with large production rates) and high-value specialty chemicals such as pharmaceuticals, dyes, and cosmetics. Commodity chemicals are produced from bacteria in very large bioreactors. For example, cultures up to 130,000 gallons are used to produce antibiotics and other therapeutics, industrial enzymes, and polymer intermediates. When a healthy bacteria culture is placed in a suitable environment with abundant nutrients, the bacteria experience balanced growth, meaning that they continue to double in number in the same fixed period of time. The doubling time of mesophilic bacteria (bacteria that live comfortably at temperatures between 35°C and 40°C) ranges anywhere from 20 minutes to a few hours. During balanced growth, the rate of growth of the bacteria is given by the expression dC dt where C(g/L) is the concentration of bacteria in the culture and u is called the specific growth rate of the bacteria (also described in Problem 2.33). The balanced growth phase eventually comes to an end, due either to the presence of a toxic byproduct or the lack of a key nutrient. The following data were measured for the growth of a particular species of mesophilic bacteria at a constant temperature: t(h) 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 C(g/L) 0.008 0.021 0.030 0.068 0.150 0.240 0.560 1.10 a. If bacteria are used in the production of a commodity chemical, would a low or high value of u be desirable? Explain. b. In the rate expression, separate the variables and integrate to derive an expression of the form f(C, Co) = µt, where C, is the bacteria concentration that would be measured at t = 0 if balanced growth extended back that far. (It might not.) What would you plot versus what on what kind of coordinates (rectangular, semilog, or log) to get a straight line if growth is balanced, and how would you determine u and C, from the plot? (Review Section 2.7 if necessary.) c. From the given data, determine whether balanced growth was maintained between t specific growth rate. (Give both its numerical value and its units.) 1h and t 8 h. If it was, calculate the d. Derive an expression for the doubling time of a bacterial species in balanced growth in terms of µ. [You may make use of your calculations in Part (b).] Calculate the doubling time of the species for which the data are given. SAFETY -2.36. The following reactions take place in a batch reactor: A +B → C (desired product) B+ C → D (hazardous product) As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the products are extracted when the concentration of D reaches 10 mol/L. The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration of D. The data are shown below: "2.36. The following reactions take place in a batch reactor: A +B → C (desired product) B+ C → D (hazardous product) As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the products are extracted when the concentration of D reaches 10 mol/L. The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration of D. The data are shown below: Cc (mol/L) Cp (mol/L) 2.8 1.4 10 2.27 20 2.95 40 3.84 70 4.74 110 5.63 160 6.49 220 7.32 a. What would be the general form of an expression for Cp as a function of Cc? b. Derive the expression. c. At what concentration of C is the reactor stopped? Answer d. Someone proposed not stopping the reaction until Cp = 13 mol/L, and someone else strongly objected. What would be the major arguments for and against that proposal? 2.37. WP The vapor pressures of 1-chlorotetradecane at several temperatures are tabulated here. T(°C) 98.5 131.8 148.2 166.2 199.8 215.5 p* (mm Hg) 5 10 20 60 100 a. Use two-point linear interpolation to estimate the value of p* at T = 185°C. b. Suppose you only know the data at 98.5°C and 215.5°C. Use two-point linear interpolation to estimate the vapor pressure at

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

The problems that are listed below need to be solved and you may access those problems via viewing them through the attached images in this request. To emphasize more, the problems are 2.35; 2.36.

![2.35. WP Bacteria can serve as catalysts for the conversion of low-cost chemicals, such as glucose, into higher value

compounds, including commodity chemicals (with large production rates) and high-value specialty chemicals such as

pharmaceuticals, dyes, and cosmetics. Commodity chemicals are produced from bacteria in very large bioreactors. For example,

cultures up to 130,000 gallons are used to produce antibiotics and other therapeutics, industrial enzymes, and polymer

intermediates.

When a healthy bacteria culture is placed in a suitable environment with abundant nutrients, the bacteria experience balanced

growth, meaning that they continue to double in number in the same fixed period of time. The doubling time of mesophilic

bacteria (bacteria that live comfortably at temperatures between 35°C and 40°C) ranges anywhere from 20 minutes to a few hours.

During balanced growth, the rate of growth of the bacteria is given by the expression

dC

dt

where C(g/L) is the concentration of bacteria in the culture and u is called the specific growth rate of the bacteria (also described

in Problem 2.33). The balanced growth phase eventually comes to an end, due either to the presence of a toxic byproduct or the

lack of a key nutrient.

The following data were measured for the growth of a particular species of mesophilic bacteria at a constant temperature:

t(h)

1.0

2.0

3.0

4.0

5.0

6.0

7.0 8.0

C(g/L) 0.008 0.021 0.030 0.068 0.150 0.240 0.560 1.10

a. If bacteria are used in the production of a commodity chemical, would a low or high value of u be desirable? Explain.

b. In the rate expression, separate the variables and integrate to derive an expression of the form f(C, Co) = µt, where C, is the

bacteria concentration that would be measured at t = 0 if balanced growth extended back that far. (It might not.) What would

you plot versus what on what kind of coordinates (rectangular, semilog, or log) to get a straight line if growth is balanced, and

how would you determine u and C, from the plot? (Review Section 2.7 if necessary.)

c. From the given data, determine whether balanced growth was maintained between t

specific growth rate. (Give both its numerical value and its units.)

1h and t

8 h. If it was, calculate the

d. Derive an expression for the doubling time of a bacterial species in balanced growth in terms of µ. [You may make use of your

calculations in Part (b).] Calculate the doubling time of the species for which the data are given.

SAFETY

-2.36. The following reactions take place in a batch reactor:

A +B → C (desired product)

B+ C → D (hazardous product)

As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure

the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the

products are extracted when the concentration of D reaches 10 mol/L.

The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration

of D. The data are shown below:](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fdf8d83c8-9746-4b83-83d4-f724fceb76b3%2F85e122e4-8a6d-40ed-aa22-55a79d8d3723%2Fyzri3k.jpeg&w=3840&q=75)

Transcribed Image Text:2.35. WP Bacteria can serve as catalysts for the conversion of low-cost chemicals, such as glucose, into higher value

compounds, including commodity chemicals (with large production rates) and high-value specialty chemicals such as

pharmaceuticals, dyes, and cosmetics. Commodity chemicals are produced from bacteria in very large bioreactors. For example,

cultures up to 130,000 gallons are used to produce antibiotics and other therapeutics, industrial enzymes, and polymer

intermediates.

When a healthy bacteria culture is placed in a suitable environment with abundant nutrients, the bacteria experience balanced

growth, meaning that they continue to double in number in the same fixed period of time. The doubling time of mesophilic

bacteria (bacteria that live comfortably at temperatures between 35°C and 40°C) ranges anywhere from 20 minutes to a few hours.

During balanced growth, the rate of growth of the bacteria is given by the expression

dC

dt

where C(g/L) is the concentration of bacteria in the culture and u is called the specific growth rate of the bacteria (also described

in Problem 2.33). The balanced growth phase eventually comes to an end, due either to the presence of a toxic byproduct or the

lack of a key nutrient.

The following data were measured for the growth of a particular species of mesophilic bacteria at a constant temperature:

t(h)

1.0

2.0

3.0

4.0

5.0

6.0

7.0 8.0

C(g/L) 0.008 0.021 0.030 0.068 0.150 0.240 0.560 1.10

a. If bacteria are used in the production of a commodity chemical, would a low or high value of u be desirable? Explain.

b. In the rate expression, separate the variables and integrate to derive an expression of the form f(C, Co) = µt, where C, is the

bacteria concentration that would be measured at t = 0 if balanced growth extended back that far. (It might not.) What would

you plot versus what on what kind of coordinates (rectangular, semilog, or log) to get a straight line if growth is balanced, and

how would you determine u and C, from the plot? (Review Section 2.7 if necessary.)

c. From the given data, determine whether balanced growth was maintained between t

specific growth rate. (Give both its numerical value and its units.)

1h and t

8 h. If it was, calculate the

d. Derive an expression for the doubling time of a bacterial species in balanced growth in terms of µ. [You may make use of your

calculations in Part (b).] Calculate the doubling time of the species for which the data are given.

SAFETY

-2.36. The following reactions take place in a batch reactor:

A +B → C (desired product)

B+ C → D (hazardous product)

As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure

the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the

products are extracted when the concentration of D reaches 10 mol/L.

The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration

of D. The data are shown below:

Transcribed Image Text:"2.36. The following reactions take place in a batch reactor:

A +B → C (desired product)

B+ C → D (hazardous product)

As the reaction proceeds, D builds up in the reactor and could cause an explosion if its concentration exceeds 15 mol/L. To ensure

the safety of the plant personnel, the reaction is quenched (e.g., by cooling the reactor contents to a low temperature) and the

products are extracted when the concentration of D reaches 10 mol/L.

The concentration of C is measured in real-time, and samples are periodically taken and analyzed to determine the concentration

of D. The data are shown below:

Cc (mol/L) Cp (mol/L)

2.8

1.4

10

2.27

20

2.95

40

3.84

70

4.74

110

5.63

160

6.49

220

7.32

a. What would be the general form of an expression for Cp as a function of Cc?

b. Derive the expression.

c. At what concentration of C is the reactor stopped?

Answer

d. Someone proposed not stopping the reaction until Cp = 13 mol/L, and someone else strongly objected. What would be the

major arguments for and against that proposal?

2.37. WP The vapor pressures of 1-chlorotetradecane at several temperatures are tabulated here.

T(°C)

98.5 131.8 148.2 166.2 199.8 215.5

p* (mm Hg)

5

10

20

60

100

a. Use two-point linear interpolation to estimate the value of p* at T = 185°C.

b. Suppose you only know the data at 98.5°C and 215.5°C. Use two-point linear interpolation to estimate the vapor pressure at

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 7 steps with 7 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The