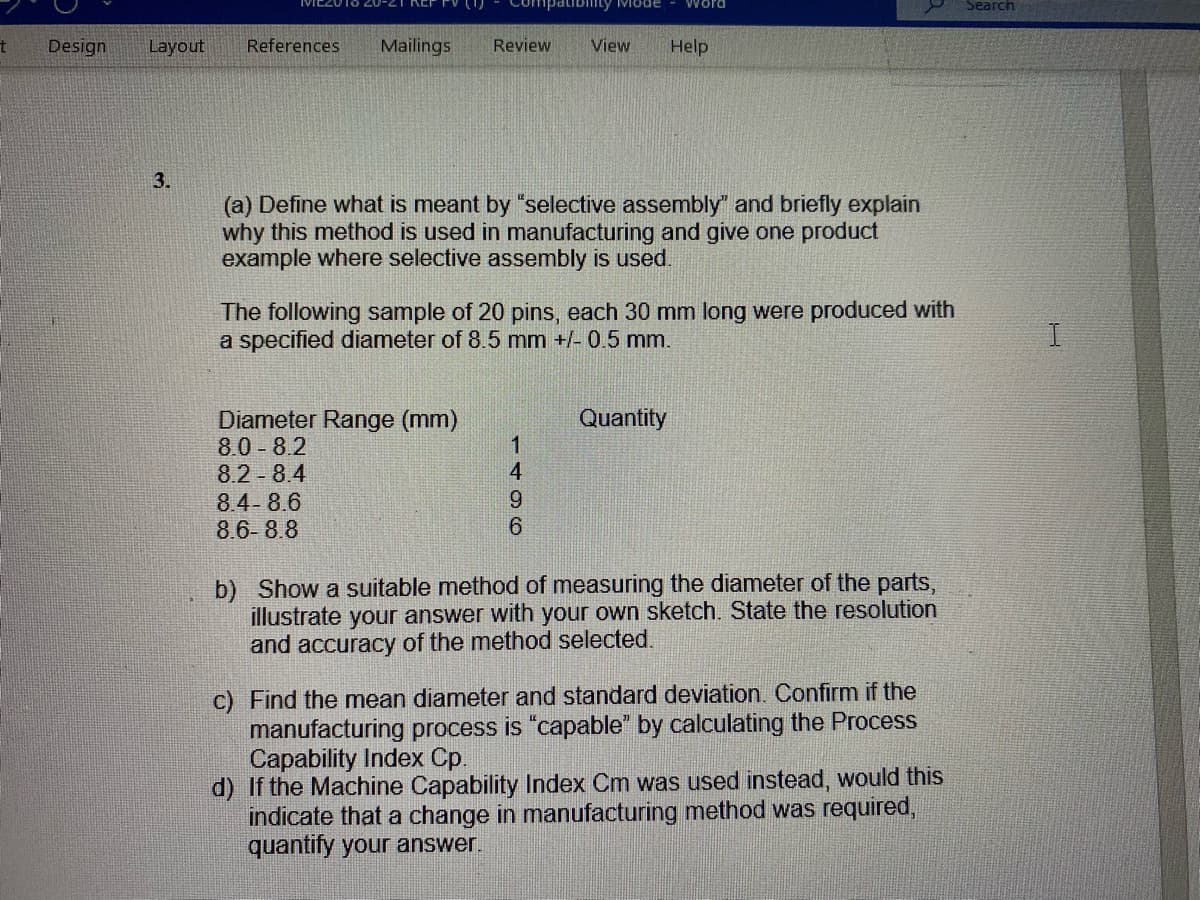

(a) Define what is meant by "selective assembly" and briefly explain why this method is used in manufacturing and give one product example where selective assembly is used. The following sample of 20 pins, each 30 mm long were produced with a specified diameter of 8.5 mm +/- 0.5 mm. Diameter Range (mm) 8.0 8.2 8.2 8.4 Quantity 4 8.4-8.6 8.6-8.8 9. 6. b) Show a suitable method of measuring the diameter of the parts, illustrate your answer with your own sketch. State the resolution and accuracy of the method selected. c) Find the mean diameter and standard deviation. Confirm if the manufacturing process is "capable" by calculating the Process Capability Index Cp. d) If the Machine Capability Index Cm was used instead, would this indicate that a change in manufacturing method was required, quantify your answer.

(a) Define what is meant by "selective assembly" and briefly explain why this method is used in manufacturing and give one product example where selective assembly is used. The following sample of 20 pins, each 30 mm long were produced with a specified diameter of 8.5 mm +/- 0.5 mm. Diameter Range (mm) 8.0 8.2 8.2 8.4 Quantity 4 8.4-8.6 8.6-8.8 9. 6. b) Show a suitable method of measuring the diameter of the parts, illustrate your answer with your own sketch. State the resolution and accuracy of the method selected. c) Find the mean diameter and standard deviation. Confirm if the manufacturing process is "capable" by calculating the Process Capability Index Cp. d) If the Machine Capability Index Cm was used instead, would this indicate that a change in manufacturing method was required, quantify your answer.

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Please answer 3c with working out and 3D as the others have already been answered and label each part

![0.0019

0.0384

0 0051

|0.0094

Help

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.00

0.01

0.02

0.4641

0.4247

0.3859

0.3483

0.3121

0.2776

0.2451

0.2148

0.1867

0.1611

0.1379

0.1170

0.0985

0.0823

0.0681

0.0559

0.0455

0.0367

0.0294

0.0233

0.0183

0.0143

0.0110

0.0084

0.0064

0.0043

0.0036

0.0026

0.0019

0.0014

0.00100

0.00071

0.00050

0.00035

0.00024

0.00017

0.4761

0.4364

0.3974

0.3594

0.3228

02877

0.2546

0,2236

0.1949

0.4721

0.4325

0.3936

0.3557

0.3192

0.4681

0.4286

0.3897

0.3520

0.3156

0.2810

0.2483

0.2177

0.1894

0.1635

0.1401

0.1190

0.1003

0.0838

0.0694

0.0571

0.0465

0.0375

0.0301

0.0239

0.0188

0.0146

0.0113

0.008

0.4840

0.4443

0.4052

0.3669

0.3300

0.4801

0.4404

0.4013

0.3632

0.3264

0.2912

0.4880

0.4483

0.4090

0.3707

0.3336

0.2981

0.2643

0.2327

0.2033

0.1762

0.1515

0.1292

0.1093

0.0918

0.0764

0.0630

0.0516

0.0418

0.0336

0.0268

0.0212

0.0166

0.0129

0.0099

0.4920

0.4522

0.4129

0.3745

0.3372

0.5000

0.4602

0.4207

0.3821

0.3346

0.3085

0.2743

0.2420

0.2119

0.1841

0.1587

0.4960

0.4562

0.4168

0.3783

0.3409

0.3050

0.2709

0.2389

0.2090

0.1814

0.1562

0.1335

0.1131

0.0951

0.0793

0.0655

0.0537

0.0

0.1

0.2

0.3

0.4

0.5

0.2843

0.2514

0.2207

0.1922

0.1660

0.3015

0.2676

0.2946

0.2611

0.2297

0.2005

0.1736

0.1492

0.1271

0.1075

0.0901

0.0749

0.0618

0.0505

0.0409

0.0329

0.0262

0.0207

0.0162

0.0125

0.0096

0.0073

0.0055

0.0041

0.0031

0.0023

0.0016

0.00118

0.00085

0.00060

0.00042

0.00029

0.00020

0.2578

0.2266

0.1977

0.6

0.7

0.8

0.9

1.0

1.1

0.2358

0.2061

0.1788

0.1539

0.1314

0.1112

0.0934

0.0778

0.0643

0.1711

0.1469

0.1251

0.1057

0.0883

0.0735

0.0606

0.0495

0.1685

0.1446

0.1230

0.1038

0.0869

0.0721

0.0594

0.0485

0.0392

0.1423

0.1210

0.1020

0.0853

0.0708

0.0582

0.0475

0.0384

0.0307

0.0244

0,0192

0.0150

0.0116

0.1357

0.1151

0.0968

0.0808

0.0668

0.0548

0.0446

0.0359

0.0287

0.0228

0.0179

0.0139

0.0107

0.0082

0.0062

0.0047

0.0035

0.0026

0.0019

0.00135

0.00097

0.00069

0.00048

0.00034

0.00023

12

| 1.3

14

15

0.0526

0.0520

0.0427

1.6

1.7

1.8

19

2.0

0.0436

0.0351

0.0281

0.0222

0.0174

0.0136

0.0104

0.0080

0.0060

0.0401

0.0322

0.0256

0.0202

0.0158

0.0122

0.0094

0.0071

0.0054

0.0040

0.0030

0.0022

0.0016

0.00114

0.00082

0.00058

0.00040

0.00028

0.00019

0.0344

0.0274

0.0217

0.0170

0.0132

00102

0.0314

0.0250

0.0197

0.0154

2.1

22

23

0.0102

0.0078

0.0059

0.0044

0.0033

0.0024

0.0017

0.00126

0.00090

0.00064

0.00045

0.00031

0.00022

0.0119

0.0091

0.0069

0.0052

0.0039

0.0029

0.0021

0.0015

0.00111

0.00079

0.00056

0.00039

0.00027

0.00019

0.0089

0.0068

0.0051

0.0038

0.0028

0.0021

0.0015

0.00107

0.00076

0.00054

0.00038

0.00026

0.00018

7

0.0066

2.4

25

2.6

2.7

2.8

2.9

3.0

3.1

3.2

33

3.4

3.5

0.0075

0.0057

0.0043

0.0032

0.0023

0.0017

0.00122

0.00087

0.00062

0.00043

0.00030

0.00021

0.0045

0.004

0.0037

0.005

0.0027

0.0045

0.0034

0.0025

0.0018

0.00131

0.00094

0.00066

0.00047

0.00033

0.00022

0.0020

0.0014

0.00104

0.00074

0.00052

0.00036

0.00025

0.00017

Statistical Table

Areas undera normal curve

Probability of a value being greater than [+X] or less than [-X]

Values in left hand column can be used for +/-Z

ZL

근u.](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fa3e605ed-e317-491a-ad79-fdcd0c75cf0e%2Fbfe0f1c4-b8a0-48bc-9b90-d0ad9f90c67c%2Fo1zs00v_processed.jpeg&w=3840&q=75)

Transcribed Image Text:0.0019

0.0384

0 0051

|0.0094

Help

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.00

0.01

0.02

0.4641

0.4247

0.3859

0.3483

0.3121

0.2776

0.2451

0.2148

0.1867

0.1611

0.1379

0.1170

0.0985

0.0823

0.0681

0.0559

0.0455

0.0367

0.0294

0.0233

0.0183

0.0143

0.0110

0.0084

0.0064

0.0043

0.0036

0.0026

0.0019

0.0014

0.00100

0.00071

0.00050

0.00035

0.00024

0.00017

0.4761

0.4364

0.3974

0.3594

0.3228

02877

0.2546

0,2236

0.1949

0.4721

0.4325

0.3936

0.3557

0.3192

0.4681

0.4286

0.3897

0.3520

0.3156

0.2810

0.2483

0.2177

0.1894

0.1635

0.1401

0.1190

0.1003

0.0838

0.0694

0.0571

0.0465

0.0375

0.0301

0.0239

0.0188

0.0146

0.0113

0.008

0.4840

0.4443

0.4052

0.3669

0.3300

0.4801

0.4404

0.4013

0.3632

0.3264

0.2912

0.4880

0.4483

0.4090

0.3707

0.3336

0.2981

0.2643

0.2327

0.2033

0.1762

0.1515

0.1292

0.1093

0.0918

0.0764

0.0630

0.0516

0.0418

0.0336

0.0268

0.0212

0.0166

0.0129

0.0099

0.4920

0.4522

0.4129

0.3745

0.3372

0.5000

0.4602

0.4207

0.3821

0.3346

0.3085

0.2743

0.2420

0.2119

0.1841

0.1587

0.4960

0.4562

0.4168

0.3783

0.3409

0.3050

0.2709

0.2389

0.2090

0.1814

0.1562

0.1335

0.1131

0.0951

0.0793

0.0655

0.0537

0.0

0.1

0.2

0.3

0.4

0.5

0.2843

0.2514

0.2207

0.1922

0.1660

0.3015

0.2676

0.2946

0.2611

0.2297

0.2005

0.1736

0.1492

0.1271

0.1075

0.0901

0.0749

0.0618

0.0505

0.0409

0.0329

0.0262

0.0207

0.0162

0.0125

0.0096

0.0073

0.0055

0.0041

0.0031

0.0023

0.0016

0.00118

0.00085

0.00060

0.00042

0.00029

0.00020

0.2578

0.2266

0.1977

0.6

0.7

0.8

0.9

1.0

1.1

0.2358

0.2061

0.1788

0.1539

0.1314

0.1112

0.0934

0.0778

0.0643

0.1711

0.1469

0.1251

0.1057

0.0883

0.0735

0.0606

0.0495

0.1685

0.1446

0.1230

0.1038

0.0869

0.0721

0.0594

0.0485

0.0392

0.1423

0.1210

0.1020

0.0853

0.0708

0.0582

0.0475

0.0384

0.0307

0.0244

0,0192

0.0150

0.0116

0.1357

0.1151

0.0968

0.0808

0.0668

0.0548

0.0446

0.0359

0.0287

0.0228

0.0179

0.0139

0.0107

0.0082

0.0062

0.0047

0.0035

0.0026

0.0019

0.00135

0.00097

0.00069

0.00048

0.00034

0.00023

12

| 1.3

14

15

0.0526

0.0520

0.0427

1.6

1.7

1.8

19

2.0

0.0436

0.0351

0.0281

0.0222

0.0174

0.0136

0.0104

0.0080

0.0060

0.0401

0.0322

0.0256

0.0202

0.0158

0.0122

0.0094

0.0071

0.0054

0.0040

0.0030

0.0022

0.0016

0.00114

0.00082

0.00058

0.00040

0.00028

0.00019

0.0344

0.0274

0.0217

0.0170

0.0132

00102

0.0314

0.0250

0.0197

0.0154

2.1

22

23

0.0102

0.0078

0.0059

0.0044

0.0033

0.0024

0.0017

0.00126

0.00090

0.00064

0.00045

0.00031

0.00022

0.0119

0.0091

0.0069

0.0052

0.0039

0.0029

0.0021

0.0015

0.00111

0.00079

0.00056

0.00039

0.00027

0.00019

0.0089

0.0068

0.0051

0.0038

0.0028

0.0021

0.0015

0.00107

0.00076

0.00054

0.00038

0.00026

0.00018

7

0.0066

2.4

25

2.6

2.7

2.8

2.9

3.0

3.1

3.2

33

3.4

3.5

0.0075

0.0057

0.0043

0.0032

0.0023

0.0017

0.00122

0.00087

0.00062

0.00043

0.00030

0.00021

0.0045

0.004

0.0037

0.005

0.0027

0.0045

0.0034

0.0025

0.0018

0.00131

0.00094

0.00066

0.00047

0.00033

0.00022

0.0020

0.0014

0.00104

0.00074

0.00052

0.00036

0.00025

0.00017

Statistical Table

Areas undera normal curve

Probability of a value being greater than [+X] or less than [-X]

Values in left hand column can be used for +/-Z

ZL

근u.

Transcribed Image Text:npatibinty VIode

Word

Search

Design

Layout

References

Mailings

Review

View

Help

3.

(a) Define what is meant by "selective assembly" and briefly explain

why this method is used in manufacturing and give one product

example where selective assembly is used.

The following sample of 20 pins, each 30 mm long were produced with

a specified diameter of 8.5 mm +/- 0.5 mm.

Diameter Range (mm)

8.0 8.2

8.2 8.4

8.4-8.6

8.6-8.8

Quantity

b) Show a suitable method of measuring the diameter of the parts,

illustrate your answer with your own sketch. State the resolution

and accuracy of the method selected.

c) Find the mean diameter and standard deviation. Confirm if the

manufacturing process is "capable" by calculating the Process

Capability Index Cp.

d) If the Machine Capability Index Cm was used instead, would this

indicate that a change in manufacturing method was required,

quantify your answer.

1496

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 3 steps with 1 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY