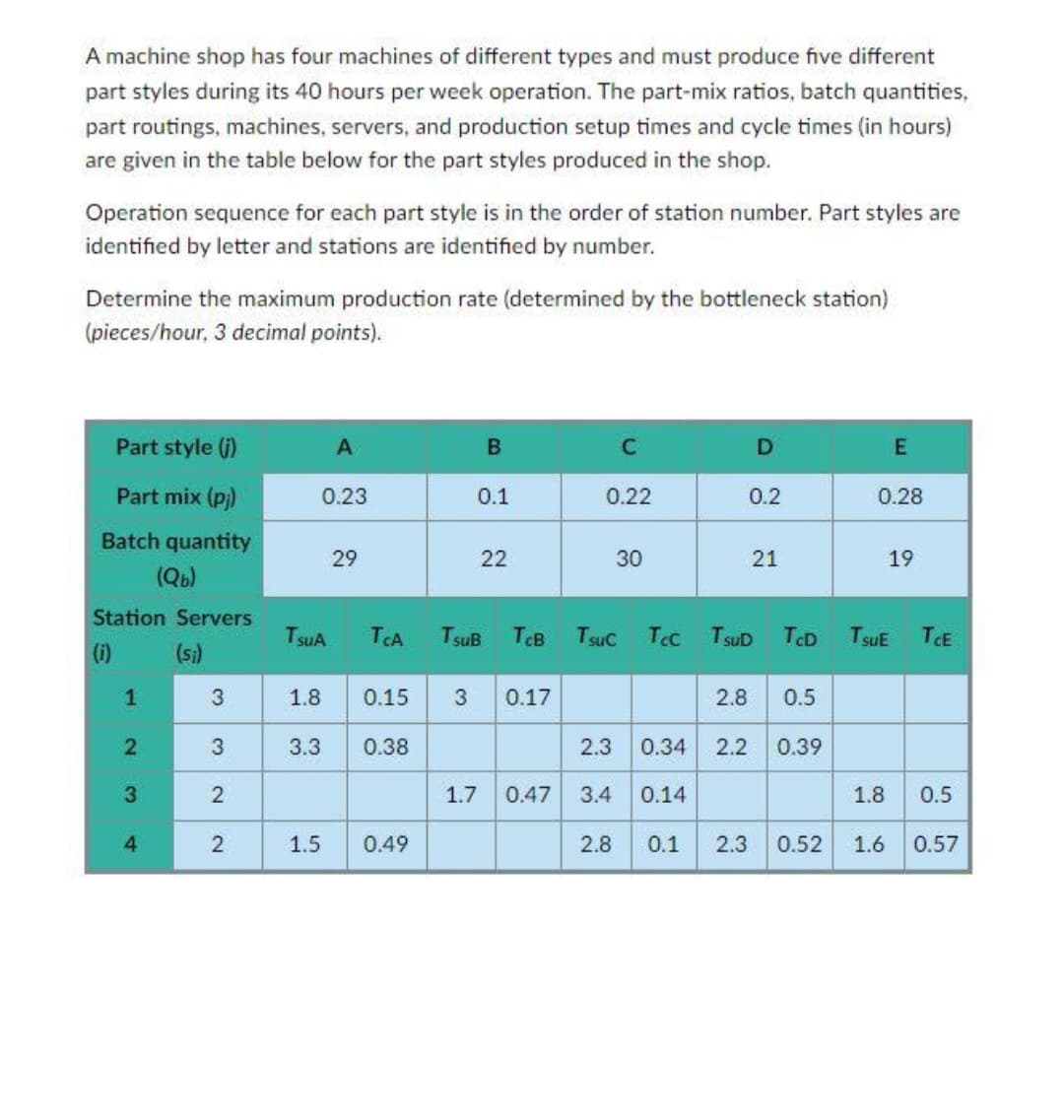

A machine shop has four machines of different types and must produce five different part styles during its 40 hours per week operation. The part-mix ratios, batch quantities, part routings, machines, servers, and production setup times and cycle times (in hours) are given in the table below for the part styles produced in the shop. Operation sequence for each part style is in the order of station number. Part styles are identified by letter and stations are identified by number. Determine the maximum production rate (determined by the bottleneck station) (pieces/hour, 3 decimal points). Part style (i) Part mix (pj) Batch quantity (Qb) Station Servers (i) (si) 1 2 3 4 3 3 2 2 A 0.23 TSUA 29 TCA 3.3 0.38 B 0.1 1.5 0.49 22 1.8 0.15 3 0.17 1.7 0.47 0.22 C 2.3 3.4 30 D 0.2 TsuB TcB Tsuc TCC TsuD TcD TSUE TCE 2.8 0.1 21 2.8 0.5 0.34 2.2 0.39 0.14 E 0.28 19 1.8 0.5 2.3 0.52 1.6 0.57

A machine shop has four machines of different types and must produce five different part styles during its 40 hours per week operation. The part-mix ratios, batch quantities, part routings, machines, servers, and production setup times and cycle times (in hours) are given in the table below for the part styles produced in the shop. Operation sequence for each part style is in the order of station number. Part styles are identified by letter and stations are identified by number. Determine the maximum production rate (determined by the bottleneck station) (pieces/hour, 3 decimal points). Part style (i) Part mix (pj) Batch quantity (Qb) Station Servers (i) (si) 1 2 3 4 3 3 2 2 A 0.23 TSUA 29 TCA 3.3 0.38 B 0.1 1.5 0.49 22 1.8 0.15 3 0.17 1.7 0.47 0.22 C 2.3 3.4 30 D 0.2 TsuB TcB Tsuc TCC TsuD TcD TSUE TCE 2.8 0.1 21 2.8 0.5 0.34 2.2 0.39 0.14 E 0.28 19 1.8 0.5 2.3 0.52 1.6 0.57

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter12: Queueing Models

Section: Chapter Questions

Problem 59P

Related questions

Question

Plz solve within 40 min I vill upvote and vill give positive feedback thank you sir

Transcribed Image Text:A machine shop has four machines of different types and must produce five different

part styles during its 40 hours per week operation. The part-mix ratios, batch quantities,

part routings, machines, servers, and production setup times and cycle times (in hours)

are given in the table below for the part styles produced in the shop.

Operation sequence for each part style is in the order of station number. Part styles are

identified by letter and stations are identified by number.

Determine the maximum production rate (determined by the bottleneck station)

(pieces/hour, 3 decimal points).

Part style (j)

Part mix (pj)

Batch quantity

(Qb)

Station Servers

(i)

(si)

1

2

3

4

3

3

2

2

A

0.23

29

TSUA TCA

B

1.5 0.49

0.1

22

1.8 0.15 3 0.17

3.3 0.38

C

0.22

TsuB TcB Tsuc

1.7 0.47

30

2.3

3.4

TCC

D

0.2

21

2.8 0.5

0.39

E

0.28

TSUD TCD TSUE

19

0.34 2.2

0.14

2.8 0.1 2.3 0.52 1.6 0.57

TCE

1.8 0.5

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,