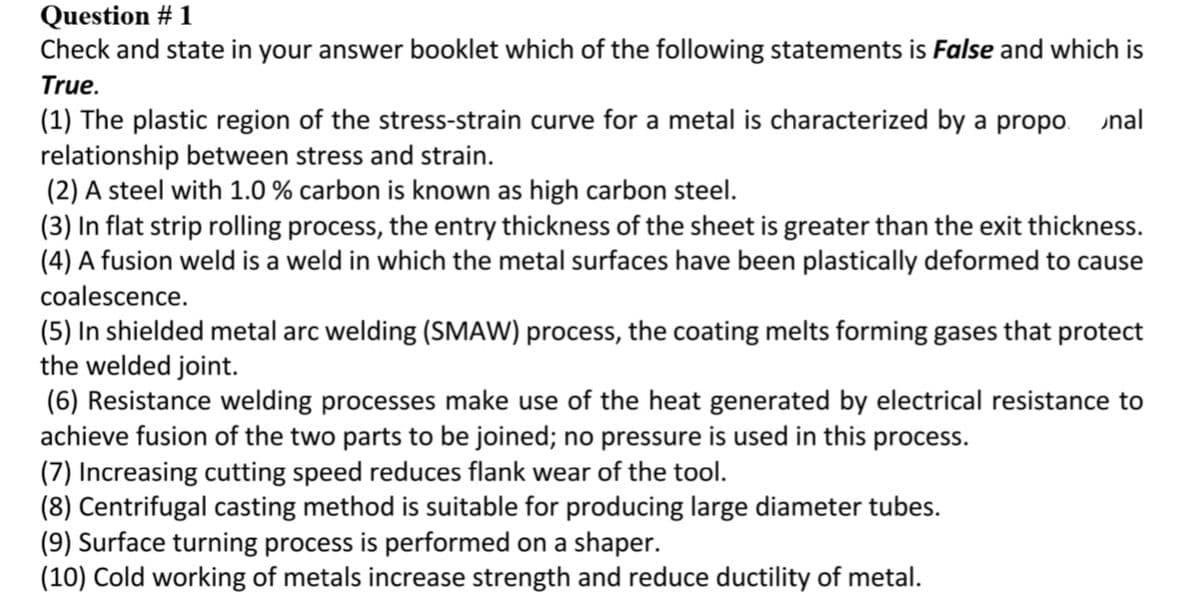

Check and state in your answer booklet which of the following statements is False and which is True. (1) The plastic region of the stress-strain curve for a metal is characterized by a propo nal relationship between stress and strain. (2) A steel with 1.0 % carbon is known as high carbon steel. (3) In flat strip rolling process, the entry thickness of the sheet is greater than the exit thickness. (4) A fusion weld is a weld in which the metal surfaces have been plastically deformed to cause coalescence. (5) In shielded metal arc welding (SMAW) process, the coating melts forming gases that protect the welded joint. (6) Resistance welding processes make use of the heat generated by electrical resistance to achieve fusion of the two parts to be joined; no pressure is used in this process. (7) Increasing cutting speed reduces flank wear of the tool. (8) Centrifugal casting method is suitable for producing large diameter tubes. (9) Surface turning process is performed on a shaper. (10) Cold working of metals increase strength and reduce ductility of metal.

Theory and Design for Mechanical Measurements

Measurement is a term that refers to analyzing a manufactured component regarding the degree of accuracy for dimensions, tolerances, geometric profile, roundness, flatness, smoothness, etc. Measurement always involves comparing the manufactured component or the prototype with a standard specimen whose dimensions and other parameters are assumed to be perfect and do not undergo changes with respect to time.Precisely in mechanical engineering the branch that deals with the application of scientific principles for measurements is known as metrology. The domain of metrology in general deals with various measurements like mechanical, chemical, thermodynamic, physical, and biological measurements. In mechanical engineering, the measurements are limited to mechanical specific such as length, mass, surface profile, flatness, roundness, viscosity, heat transfer, etc.

Basic principles of engineering metrology

Metrology is described as the science of measurement, precision, and accuracy. In other words, it is a method of measurement based on units and predefined standards.

This is a True or false question that has been bothersome please help

Trending now

This is a popular solution!

Step by step

Solved in 2 steps