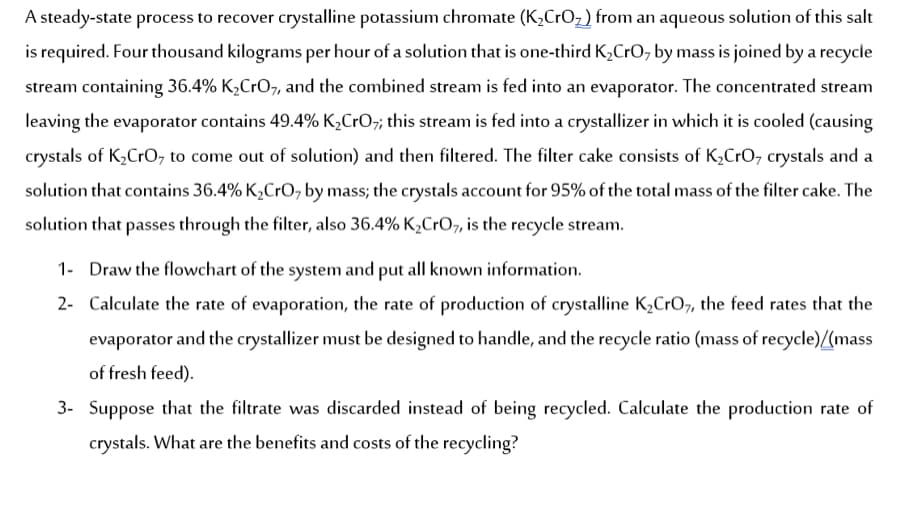

d. Four thousand kilograms per hour of a solution that is one-third K,Cr0, by mass is joined by a r ontaining 36.4% K,CrO, and the combined stream is fed into an evaporator. The concentrated ne evaporator contains 49.4% K,CrO,; this stream is fed into a crystallizer in which it is cooled (c of K2CRO, to come out of solution) and then filtered. The filter cake consists of K,CrO, crystals that contains 36.4% K¿CrO, by mass; the crystals account for 95% of the total mass of the filter cak that passes through the filter, also 36.4% K2CrO7, is the recycle stream.

Catalysis and Enzymatic Reactions

Catalysis is the kind of chemical reaction in which the rate (speed) of a reaction is enhanced by the catalyst which is not consumed during the process of reaction and afterward it is removed when the catalyst is not used to make up the impurity in the product. The enzymatic reaction is the reaction that is catalyzed via enzymes.

Lock And Key Model

The lock-and-key model is used to describe the catalytic enzyme activity, based on the interaction between enzyme and substrate. This model considers the lock as an enzyme and the key as a substrate to explain this model. The concept of how a unique distinct key only can have the access to open a particular lock resembles how the specific substrate can only fit into the particular active site of the enzyme. This is significant in understanding the intermolecular interaction between proteins and plays a vital role in drug interaction.

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 1 images