Data p = 950 n³ T = 350 K 150L mol-K Mw.DMF = 73.1 gm mol Cy = Viia = 2 m3 kg w = 180- min T = 325 K P = 1 bar X1 = 0.9 %3D kg i = 0.6 W1 = 200- min %3D Antoine equation for DMF: в log10 PEF = A – C+T' , with Psat[=] bar and T[=] K A = 3.93068 B = 1337.716 C = -82.648

Data p = 950 n³ T = 350 K 150L mol-K Mw.DMF = 73.1 gm mol Cy = Viia = 2 m3 kg w = 180- min T = 325 K P = 1 bar X1 = 0.9 %3D kg i = 0.6 W1 = 200- min %3D Antoine equation for DMF: в log10 PEF = A – C+T' , with Psat[=] bar and T[=] K A = 3.93068 B = 1337.716 C = -82.648

Chemistry

10th Edition

ISBN:9781305957404

Author:Steven S. Zumdahl, Susan A. Zumdahl, Donald J. DeCoste

Publisher:Steven S. Zumdahl, Susan A. Zumdahl, Donald J. DeCoste

Chapter1: Chemical Foundations

Section: Chapter Questions

Problem 1RQ: Define and explain the differences between the following terms. a. law and theory b. theory and...

Related questions

Question

![Data

kg

p = 950

m3

Cy = 150L

mol·K

Mw.DMF = 73.1 gm

mol

Viia = 2 m3

T = 350 K

T = 325 K

X1 = 0.9

kg

w = 180

min

ī = 0.6

P = 1 bar

W1 = 200-

min

kg

Antoine equation for DMF:

B

log10 PEiE = A –

C+T'

with Psat[=] bar and T[=] K

A = 3.93068

B = 1337.716 C = -82.648](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fe5d528f6-f704-4253-8470-44f2fbc0de86%2Fdffe3160-8dff-4977-a8bb-0fab1b2d4e41%2Fdmi5msd_processed.jpeg&w=3840&q=75)

Transcribed Image Text:Data

kg

p = 950

m3

Cy = 150L

mol·K

Mw.DMF = 73.1 gm

mol

Viia = 2 m3

T = 350 K

T = 325 K

X1 = 0.9

kg

w = 180

min

ī = 0.6

P = 1 bar

W1 = 200-

min

kg

Antoine equation for DMF:

B

log10 PEiE = A –

C+T'

with Psat[=] bar and T[=] K

A = 3.93068

B = 1337.716 C = -82.648

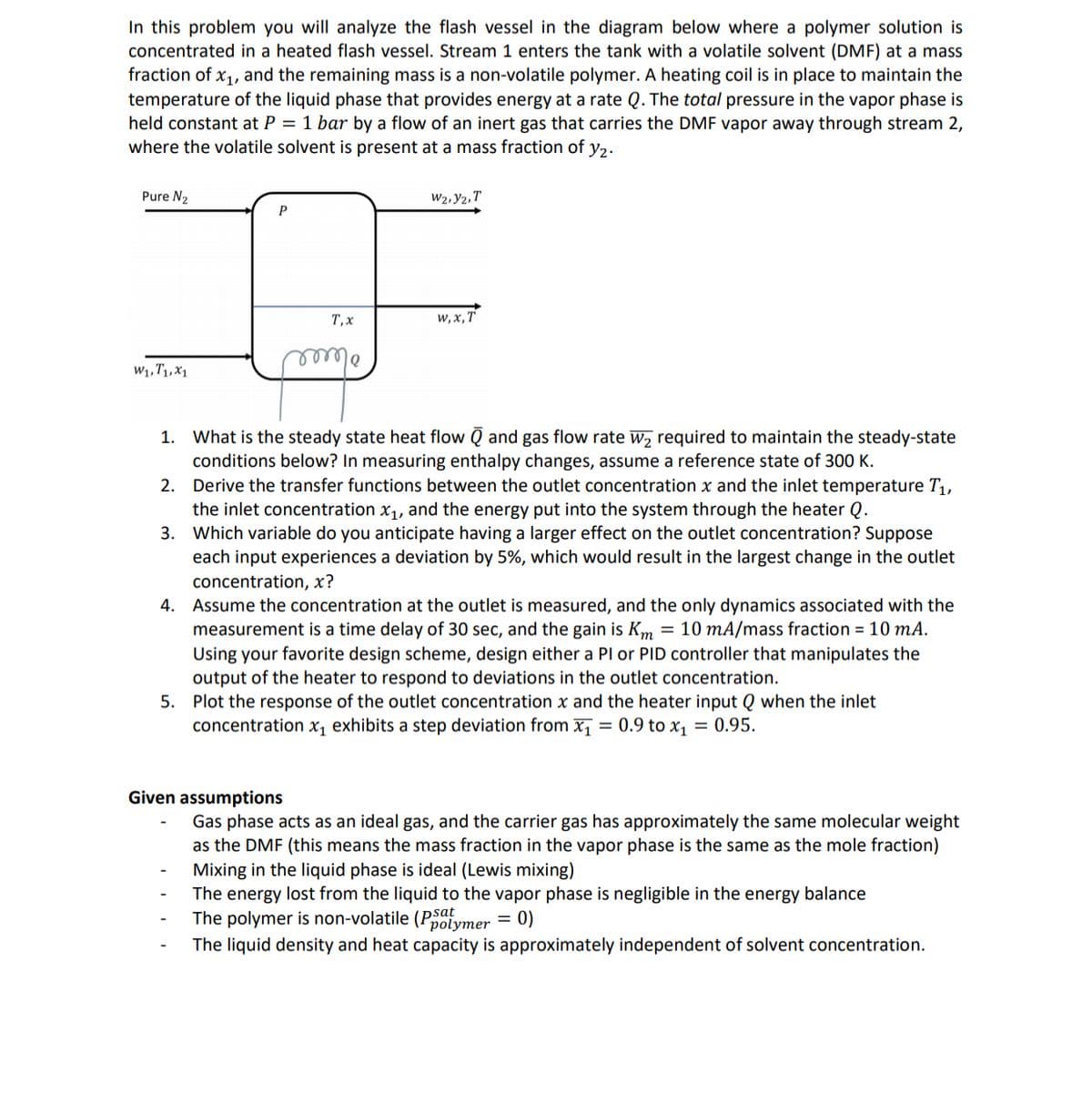

Transcribed Image Text:In this problem you will analyze the flash vessel in the diagram below where a polymer solution is

concentrated in a heated flash vessel. Stream 1 enters the tank with a volatile solvent (DMF) at a mass

fraction of x1, and the remaining mass is a non-volatile polymer. A heating coil is in place to maintain the

temperature of the liquid phase that provides energy at a rate Q. The total pressure in the vapor phase is

held constant at P = 1 bar by a flow of an inert gas that carries the DMF vapor away through stream 2,

where the volatile solvent is present at a mass fraction of y2.

Pure N2

W2, Y2, T

P

T, x

w, x, T

W1,T1,X1

olec

1. What is the steady state heat flow Q and gas flow rate W, required to maintain the steady-state

conditions below? In measuring enthalpy changes, assume a reference state of 300 K.

Derive the transfer functions between the outlet concentration x and the inlet temperature T,,

the inlet concentration x1, and the energy put into the system through the heater Q.

Which variable do you anticipate having a larger effect on the outlet concentration? Suppose

each input experiences a deviation by 5%, which would result in the largest change in the outlet

2.

3.

concentration, x?

4. Assume the concentration at the outlet is measured, and the only dynamics associated with the

measurement is a time delay of 30 sec, and the gain is Km = 10 mA/mass fraction = 10 mA.

Using your favorite design scheme, design either a Pl or PID controller that manipulates the

output of the heater to respond to deviations in the outlet concentration.

5. Plot the response of the outlet concentration x and the heater input Q when the inlet

concentration x, exhibits a step deviation from x, = 0.9 to x, = 0.95.

Given assumptions

Gas phase acts as an ideal gas, and the carrier gas has approximately the same molecular weight

as the DMF (this means the mass fraction in the vapor phase is the same as the mole fraction)

Mixing in the liquid phase is ideal (Lewis mixing)

The energy lost from the liquid to the vapor phase is negligible in the energy balance

The polymer is non-volatile (Polymer = 0)

The liquid density and heat capacity is approximately independent of solvent concentration.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemistry and related others by exploring similar questions and additional content below.Recommended textbooks for you

Chemistry

Chemistry

ISBN:

9781305957404

Author:

Steven S. Zumdahl, Susan A. Zumdahl, Donald J. DeCoste

Publisher:

Cengage Learning

Chemistry

Chemistry

ISBN:

9781259911156

Author:

Raymond Chang Dr., Jason Overby Professor

Publisher:

McGraw-Hill Education

Principles of Instrumental Analysis

Chemistry

ISBN:

9781305577213

Author:

Douglas A. Skoog, F. James Holler, Stanley R. Crouch

Publisher:

Cengage Learning

Chemistry

Chemistry

ISBN:

9781305957404

Author:

Steven S. Zumdahl, Susan A. Zumdahl, Donald J. DeCoste

Publisher:

Cengage Learning

Chemistry

Chemistry

ISBN:

9781259911156

Author:

Raymond Chang Dr., Jason Overby Professor

Publisher:

McGraw-Hill Education

Principles of Instrumental Analysis

Chemistry

ISBN:

9781305577213

Author:

Douglas A. Skoog, F. James Holler, Stanley R. Crouch

Publisher:

Cengage Learning

Organic Chemistry

Chemistry

ISBN:

9780078021558

Author:

Janice Gorzynski Smith Dr.

Publisher:

McGraw-Hill Education

Chemistry: Principles and Reactions

Chemistry

ISBN:

9781305079373

Author:

William L. Masterton, Cecile N. Hurley

Publisher:

Cengage Learning

Elementary Principles of Chemical Processes, Bind…

Chemistry

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY