Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7 Average 31 35.5 31 40.5 34 39 37.5 time for Total process Average 15 20 17 18 24 time for Moulding Average 4.5 7 7 5.5 time for finishing Average time for 10 11 9. 8.5 10 8 12 packing Factory manager claims that there is a positive relationship between moulding time and total time taken for the process. As the production engineer you need to test this hypothesis using the above data. If there is a relationship, provide the best fitted straight line for the above data using linear regression. You should interpret your results in a method that can be understood by a non-technical audience. 20 25

Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7 Average 31 35.5 31 40.5 34 39 37.5 time for Total process Average 15 20 17 18 24 time for Moulding Average 4.5 7 7 5.5 time for finishing Average time for 10 11 9. 8.5 10 8 12 packing Factory manager claims that there is a positive relationship between moulding time and total time taken for the process. As the production engineer you need to test this hypothesis using the above data. If there is a relationship, provide the best fitted straight line for the above data using linear regression. You should interpret your results in a method that can be understood by a non-technical audience. 20 25

Linear Algebra: A Modern Introduction

4th Edition

ISBN:9781285463247

Author:David Poole

Publisher:David Poole

Chapter2: Systems Of Linear Equations

Section2.4: Applications

Problem 16EQ

Related questions

Question

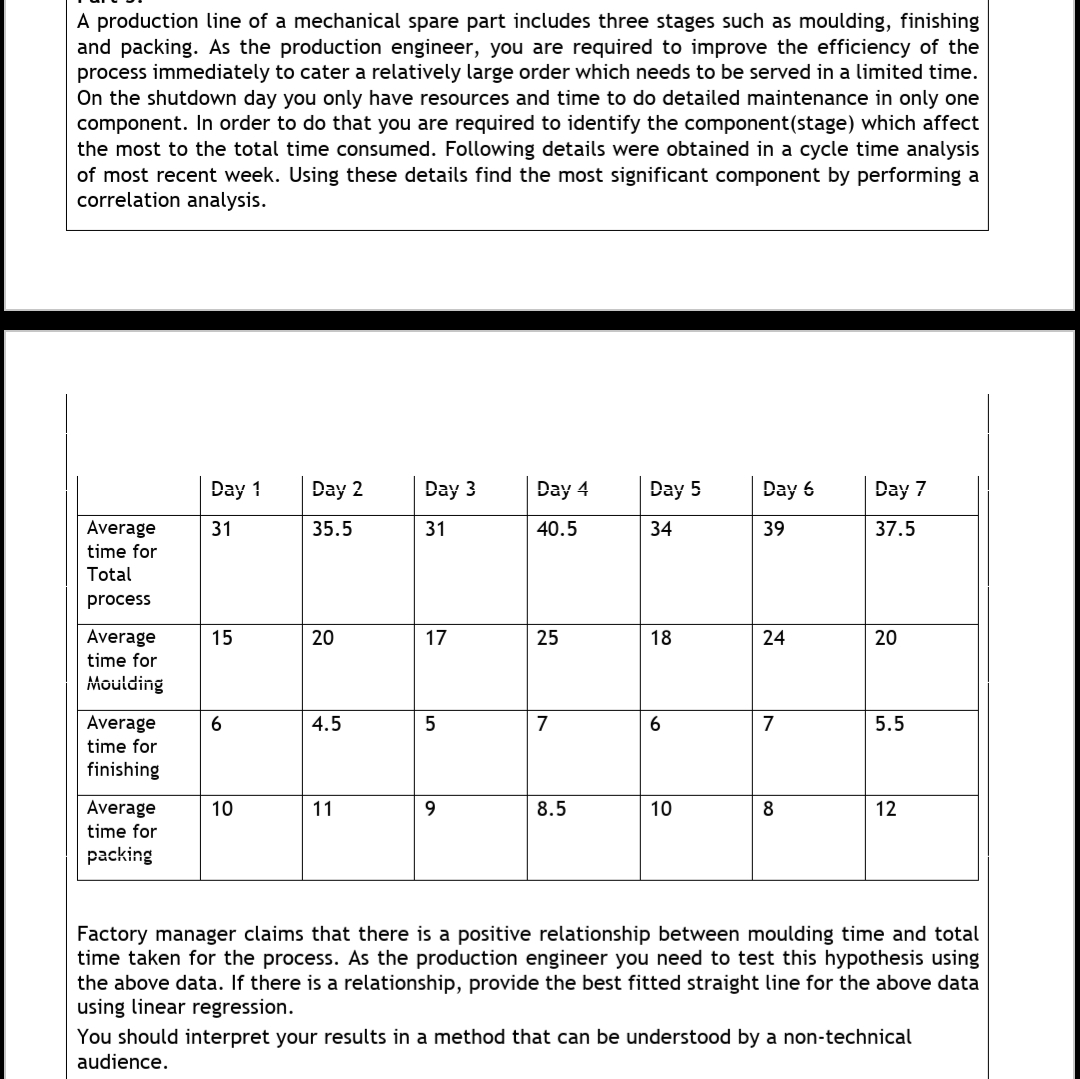

Transcribed Image Text:A production line of a mechanical spare part includes three stages such as moulding, finishing

and packing. As the production engineer, you are required to improve the efficiency of the

process immediately to cater a relatively large order which needs to be served in a limited time.

On the shutdown day you only have resources and time to do detailed maintenance in only one

component. In order to do that you are required to identify the component(stage) which affect

the most to the total time consumed. Following details were obtained in a cycle time analysis

of most recent week. Using these details find the most significant component by performing a

correlation analysis.

Day 1

Day 2

Day 3

Day 4

Day 5

Day 6

Day 7

Average

31

35.5

31

40.5

34

39

37.5

time for

Total

process

Average

15

20

17

25

18

24

20

time for

Moulding

Average

4.5

7

6.

7

5.5

time for

finishing

Average

10

11

9.

8.5

10

12

time for

packing

Factory manager claims that there is a positive relationship between moulding time and total

time taken for the process. As the production engineer you need to test this hypothesis using

the above data. If there is a relationship, provide the best fitted straight line for the above data

using linear regression.

You should interpret your results in a method that can be understood by a non-technical

audience.

co

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 2 steps

Recommended textbooks for you

Linear Algebra: A Modern Introduction

Algebra

ISBN:

9781285463247

Author:

David Poole

Publisher:

Cengage Learning

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

Linear Algebra: A Modern Introduction

Algebra

ISBN:

9781285463247

Author:

David Poole

Publisher:

Cengage Learning

Algebra for College Students

Algebra

ISBN:

9781285195780

Author:

Jerome E. Kaufmann, Karen L. Schwitters

Publisher:

Cengage Learning

College Algebra

Algebra

ISBN:

9781305115545

Author:

James Stewart, Lothar Redlin, Saleem Watson

Publisher:

Cengage Learning