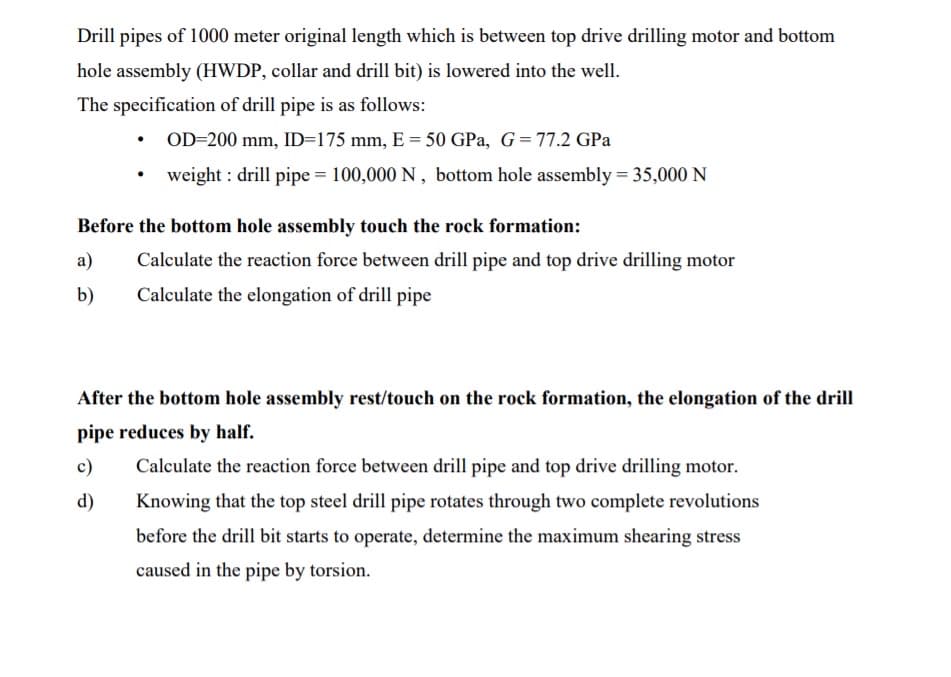

Drill pipes of 1000 meter original length which is between top drive drilling motor and bottom hole assembly (HWDP, collar and drill bit) is lowered into the well. The specification of drill pipe is as follows: • OD=200 mm, ID=175 mm, E = 50 GPa, G= 77.2 GPa weight : drill pipe = 100,000 N, bottom hole assembly = 35,000 N Before the bottom hole assembly touch the rock formation: a) Calculate the reaction force between drill pipe and top drive drilling motor b) Calculate the elongation of drill pipe After the bottom hole assembly rest/touch on the rock formation, the elongation of the drill pipe reduces by half. c) Calculate the reaction force between drill pipe and top drive drilling motor. d) Knowing that the top steel drill pipe rotates through two complete revolutions before the drill bit starts to operate, determine the maximum shearing stress caused in the pipe by torsion.

Drill pipes of 1000 meter original length which is between top drive drilling motor and bottom hole assembly (HWDP, collar and drill bit) is lowered into the well. The specification of drill pipe is as follows: • OD=200 mm, ID=175 mm, E = 50 GPa, G= 77.2 GPa weight : drill pipe = 100,000 N, bottom hole assembly = 35,000 N Before the bottom hole assembly touch the rock formation: a) Calculate the reaction force between drill pipe and top drive drilling motor b) Calculate the elongation of drill pipe After the bottom hole assembly rest/touch on the rock formation, the elongation of the drill pipe reduces by half. c) Calculate the reaction force between drill pipe and top drive drilling motor. d) Knowing that the top steel drill pipe rotates through two complete revolutions before the drill bit starts to operate, determine the maximum shearing stress caused in the pipe by torsion.

International Edition---engineering Mechanics: Statics, 4th Edition

4th Edition

ISBN:9781305501607

Author:Andrew Pytel And Jaan Kiusalaas

Publisher:Andrew Pytel And Jaan Kiusalaas

Chapter7: Dry Friction

Section: Chapter Questions

Problem 7.35P: The weight of the cylindrical tank is negligible in comparison to the weight of water it contains...

Related questions

Topic Video

Question

Transcribed Image Text:Drill pipes of 1000 meter original length which is between top drive drilling motor and bottom

hole assembly (HWDP, collar and drill bit) is lowered into the well.

The specification of drill pipe is as follows:

• OD=200 mm, ID=175 mm, E = 50 GPa, G= 77.2 GPa

weight : drill pipe = 100,000 N , bottom hole assembly = 35,000 N

Before the bottom hole assembly touch the rock formation:

a)

Calculate the reaction force between drill pipe and top drive drilling motor

b)

Calculate the elongation of drill pipe

After the bottom hole assembly rest/touch on the rock formation, the elongation of the drill

pipe reduces by half.

c)

Calculate the reaction force between drill pipe and top drive drilling motor.

d)

Knowing that the top steel drill pipe rotates through two complete revolutions

before the drill bit starts to operate, determine the maximum shearing stress

caused in the pipe by torsion.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

International Edition---engineering Mechanics: St…

Mechanical Engineering

ISBN:

9781305501607

Author:

Andrew Pytel And Jaan Kiusalaas

Publisher:

CENGAGE L

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning