For many years, Thomson Company manufactured a single product called LEC 40. Then three years ago, the company automated a portion of its plant and at the same time introduced a second product called LEC 90 that has become increasingly popular. The LEC 90 is a more complex product, requiring 0.80 hours of direct labor time per unit to manufacture and extensive machining in the automated portion of the plant. The LEC 40 requires only 0.40 hours of direct labor time per unit and only a small amount of machining. Manufacturing overhead costs are currently assigned to products on the basis of direct labor-hours. Despite the growing popularity of the company's new LEC 90, profits have been declining steadily. Management is beginning to believe that there may be a problem with the company's costing system. Direct material and direct labor costs per unit are as follows: Direct materials Direct labor (0.40 hours and 0.80 hours @ $10.00 per hour) LEC 40 LEC 90 $40.00 $20.00 $ 4.00 $ 8.00 Management estimates that the company will incur $728,000 in manufacturing overhead costs during the current year and 60,000 units of the LEC 40 and 20,000 units of the LEC 90 will be produced and sold.

For many years, Thomson Company manufactured a single product called LEC 40. Then three years ago, the company automated a portion of its plant and at the same time introduced a second product called LEC 90 that has become increasingly popular. The LEC 90 is a more complex product, requiring 0.80 hours of direct labor time per unit to manufacture and extensive machining in the automated portion of the plant. The LEC 40 requires only 0.40 hours of direct labor time per unit and only a small amount of machining. Manufacturing overhead costs are currently assigned to products on the basis of direct labor-hours. Despite the growing popularity of the company's new LEC 90, profits have been declining steadily. Management is beginning to believe that there may be a problem with the company's costing system. Direct material and direct labor costs per unit are as follows: Direct materials Direct labor (0.40 hours and 0.80 hours @ $10.00 per hour) LEC 40 LEC 90 $40.00 $20.00 $ 4.00 $ 8.00 Management estimates that the company will incur $728,000 in manufacturing overhead costs during the current year and 60,000 units of the LEC 40 and 20,000 units of the LEC 90 will be produced and sold.

Cornerstones of Cost Management (Cornerstones Series)

4th Edition

ISBN:9781305970663

Author:Don R. Hansen, Maryanne M. Mowen

Publisher:Don R. Hansen, Maryanne M. Mowen

Chapter13: The Balanced Scorecard: Strategic-based Control

Section: Chapter Questions

Problem 9E: Computador has a manufacturing plant in Des Moines that has the theoretical capability to produce...

Related questions

Question

Please do not give solution in image format thanku

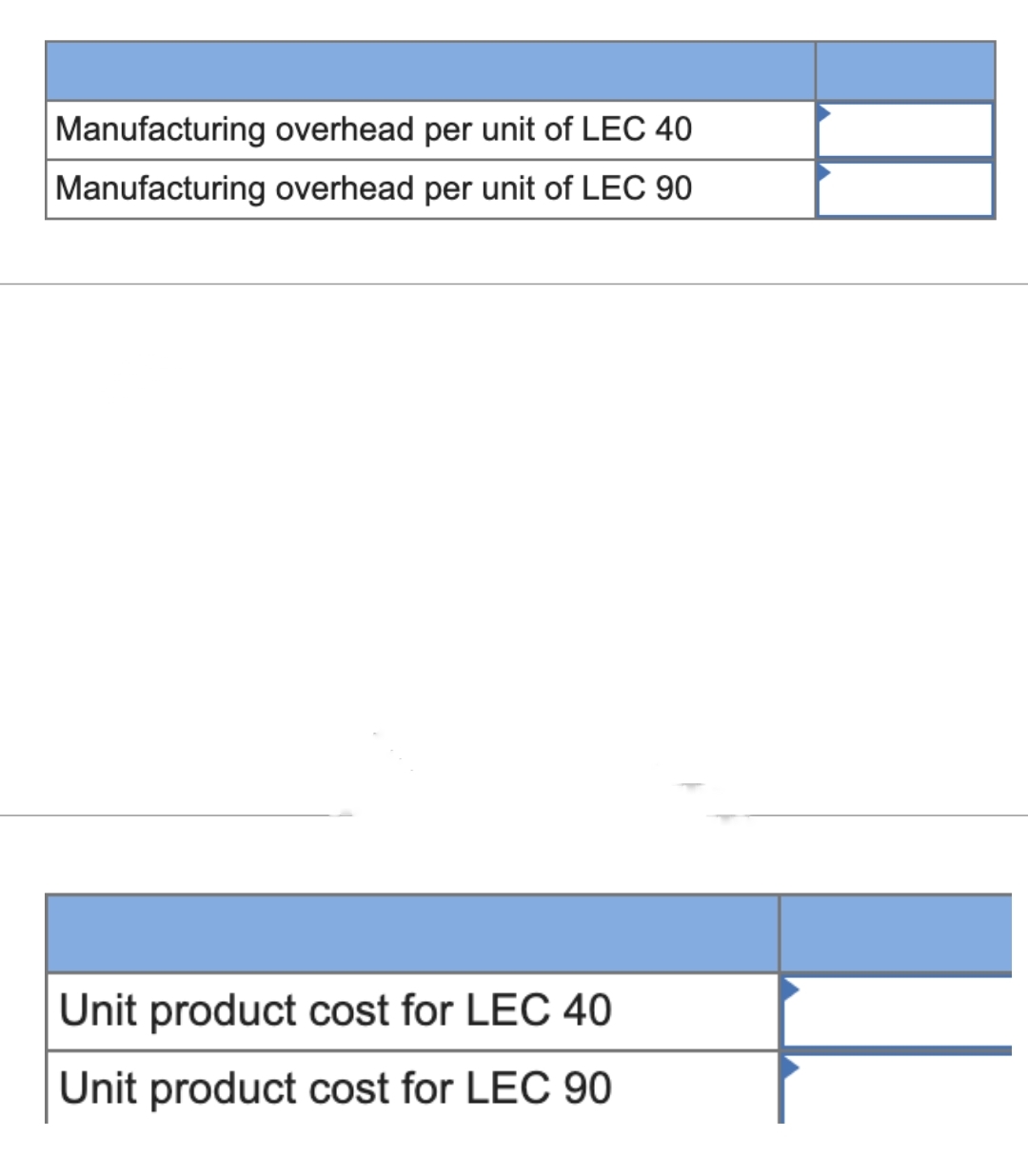

Transcribed Image Text:Manufacturing overhead per unit of LEC 40

Manufacturing overhead per unit of LEC 90

Unit product cost for LEC 40

Unit product cost for LEC 90

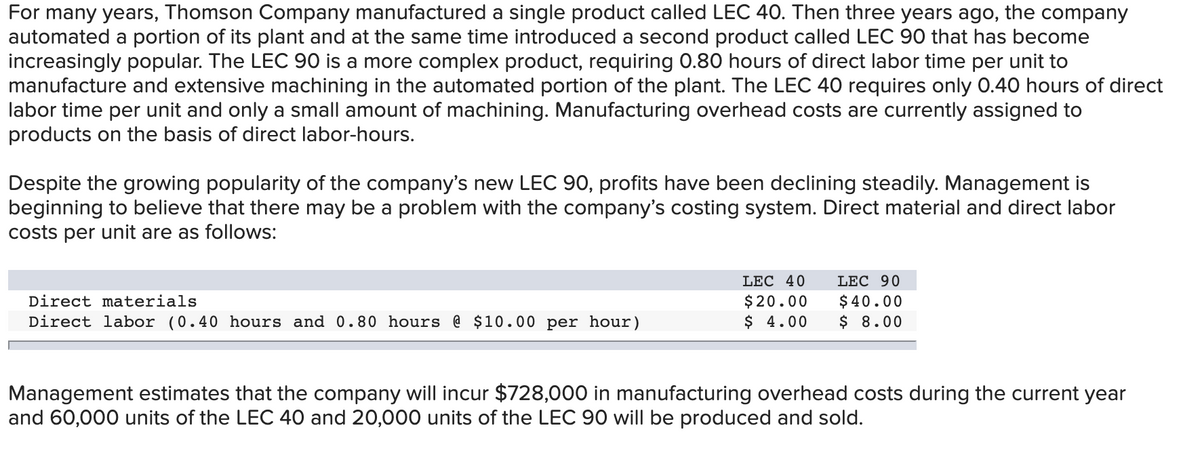

Transcribed Image Text:For many years, Thomson Company manufactured a single product called LEC 40. Then three years ago, the company

automated a portion of its plant and at the same time introduced a second product called LEC 90 that has become

increasingly popular. The LEC 90 is a more complex product, requiring 0.80 hours of direct labor time per unit to

manufacture and extensive machining in the automated portion of the plant. The LEC 40 requires only 0.40 hours of direct

labor time per unit and only a small amount of machining. Manufacturing overhead costs are currently assigned to

products on the basis of direct labor-hours.

Despite the growing popularity of the company's new LEC 90, profits have been declining steadily. Management is

beginning to believe that there may be a problem with the company's costing system. Direct material and direct labor

costs per unit are as follows:

Direct materials

Direct labor (0.40 hours and 0.80 hours @ $10.00 per hour)

LEC 90

LEC 40

$20.00

$40.00

$ 4.00 $ 8.00

Management estimates that the company will incur $728,000 in manufacturing overhead costs during the current year

and 60,000 units of the LEC 40 and 20,000 units of the LEC 90 will be produced and sold.

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, accounting and related others by exploring similar questions and additional content below.Recommended textbooks for you

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Essentials of Business Analytics (MindTap Course …

Statistics

ISBN:

9781305627734

Author:

Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:

Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser…

Accounting

ISBN:

9781305970663

Author:

Don R. Hansen, Maryanne M. Mowen

Publisher:

Cengage Learning

Principles of Cost Accounting

Accounting

ISBN:

9781305087408

Author:

Edward J. Vanderbeck, Maria R. Mitchell

Publisher:

Cengage Learning

Essentials of Business Analytics (MindTap Course …

Statistics

ISBN:

9781305627734

Author:

Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. Anderson

Publisher:

Cengage Learning

Managerial Accounting: The Cornerstone of Busines…

Accounting

ISBN:

9781337115773

Author:

Maryanne M. Mowen, Don R. Hansen, Dan L. Heitger

Publisher:

Cengage Learning

Managerial Accounting

Accounting

ISBN:

9781337912020

Author:

Carl Warren, Ph.d. Cma William B. Tayler

Publisher:

South-Western College Pub

Financial And Managerial Accounting

Accounting

ISBN:

9781337902663

Author:

WARREN, Carl S.

Publisher:

Cengage Learning,