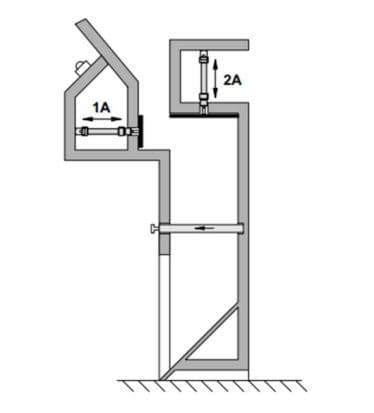

INSTRUCTION: This is a topic for Pneumatic Controls Engineering. You may use Fluidsim to illustrate the solution (circuit diagram) to the given problem. Please refer to the problem below and apply the appropriate pneumatic system circuit. PROBLEM: The prototype of a pneumatic domestic rubbish compactor (under table model) is operated with a maximum working pressure of p = 3bar = 300 kPa. It is equipped with a pre-compactor (1A) including glass crusher as well as a main compactor (2A), which exerts a maximum force of F = 2200 N. When a start button is pressed, first the pre-compactor advances, then followed by the main compactor. The subsequent return stroke of both double-acting cylinders takes place simultaneously. In the event that the main compactor does not reach the forward end position — rubbish bins full —, the return stroke of both cylinders is initiated by a pressure sequence valve. It is set to switch at p = 2.8 bar = 280 kPa.

INSTRUCTION: This is a topic for Pneumatic Controls Engineering. You may use Fluidsim to illustrate the solution (circuit diagram) to the given problem. Please refer to the problem below and apply the appropriate pneumatic system circuit.

PROBLEM: The prototype of a pneumatic domestic rubbish compactor (under table model) is operated with a maximum working pressure of p = 3bar = 300 kPa. It is equipped with a pre-compactor (1A) including glass crusher as well as a main compactor (2A), which exerts a maximum force of F = 2200 N. When a start button is pressed, first the pre-compactor advances, then followed by the main compactor. The subsequent return stroke of both double-acting cylinders takes place simultaneously. In the event that the main compactor does not reach the forward end position — rubbish bins full —, the return stroke of both cylinders is initiated by a pressure sequence valve. It is set to switch at p = 2.8 bar = 280 kPa.

Trending now

This is a popular solution!

Step by step

Solved in 2 steps with 2 images