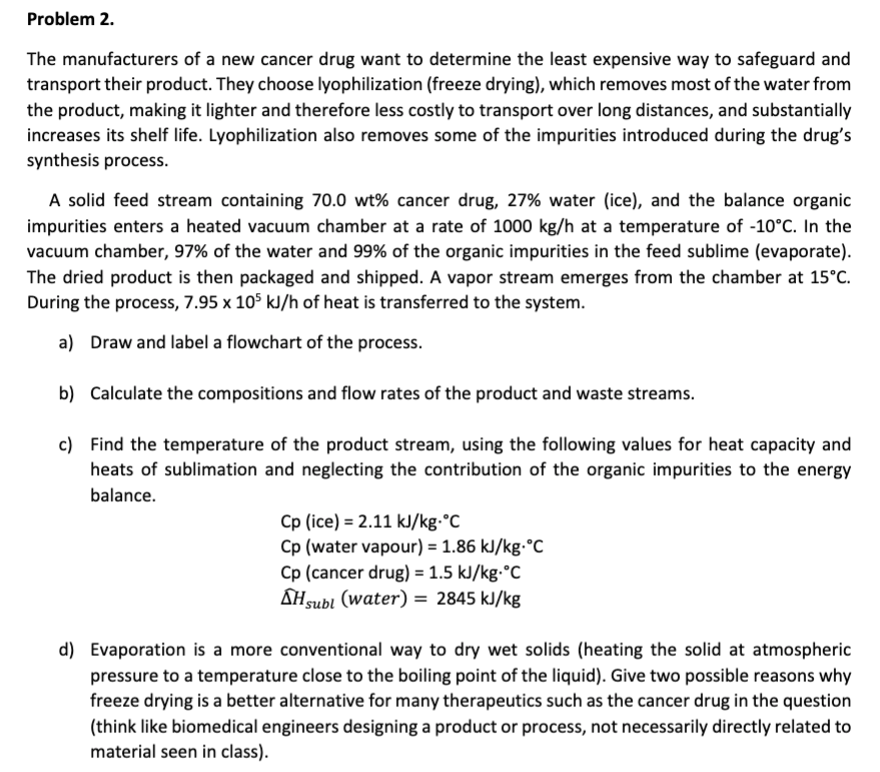

Problem 2. The manufacturers of a new cancer drug want to determine the least expensive way to safeguard and transport their product. They choose lyophilization (freeze drying), which removes most of the water from the product, making it lighter and therefore less costly to transport over long distances, and substantially increases its shelf life. Lyophilization also removes some of the impurities introduced during the drug's synthesis process. A solid feed stream containing 70.0 wt% cancer drug, 27% water (ice), and the balance organic impurities enters a heated vacuum chamber at a rate of 1000 kg/h at a temperature of -10°C. In the vacuum chamber, 97% of the water and 99% of the organic impurities in the feed sublime (evaporate) The dried product is then packaged and shipped. A vapor stream emerges from the chamber at 15'C During the process, 7.95 x 105 kl/h of heat is transferred to the system. a) Draw and label a flowchart of the process. b) Calculate the compositions and flow rates of the product and waste streams. c) Find the temperature of the product stream, using the following values for heat capacity and heats of sublimation and neglecting the contribution of the organic impurities to the energy balance. Cp (ice) 2.11 kl/kg.°C Cp (water vapour) = 1.86 kJ/kg.°C Cp (cancer drug) =1.5 kl/kg.°C AHsubl (water) 2845 kJ/kg d) Evaporation is a more conventional way to dry wet solids (heating the solid at atmospheric pressure to a temperature close to the boiling point of the liquid). Give two possible reasons why freeze drying is a better alternative for many therapeutics such as the cancer drug in the question (think like biomedical engineers designing a product or process, not necessarily directly related to material seen in class).

Problem 2. The manufacturers of a new cancer drug want to determine the least expensive way to safeguard and transport their product. They choose lyophilization (freeze drying), which removes most of the water from the product, making it lighter and therefore less costly to transport over long distances, and substantially increases its shelf life. Lyophilization also removes some of the impurities introduced during the drug's synthesis process. A solid feed stream containing 70.0 wt% cancer drug, 27% water (ice), and the balance organic impurities enters a heated vacuum chamber at a rate of 1000 kg/h at a temperature of -10°C. In the vacuum chamber, 97% of the water and 99% of the organic impurities in the feed sublime (evaporate) The dried product is then packaged and shipped. A vapor stream emerges from the chamber at 15'C During the process, 7.95 x 105 kl/h of heat is transferred to the system. a) Draw and label a flowchart of the process. b) Calculate the compositions and flow rates of the product and waste streams. c) Find the temperature of the product stream, using the following values for heat capacity and heats of sublimation and neglecting the contribution of the organic impurities to the energy balance. Cp (ice) 2.11 kl/kg.°C Cp (water vapour) = 1.86 kJ/kg.°C Cp (cancer drug) =1.5 kl/kg.°C AHsubl (water) 2845 kJ/kg d) Evaporation is a more conventional way to dry wet solids (heating the solid at atmospheric pressure to a temperature close to the boiling point of the liquid). Give two possible reasons why freeze drying is a better alternative for many therapeutics such as the cancer drug in the question (think like biomedical engineers designing a product or process, not necessarily directly related to material seen in class).

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:Problem 2.

The manufacturers of a new cancer drug want to determine the least expensive way to safeguard and

transport their product. They choose lyophilization (freeze drying), which removes most of the water from

the product, making it lighter and therefore less costly to transport over long distances, and substantially

increases its shelf life. Lyophilization also removes some of the impurities introduced during the drug's

synthesis process.

A solid feed stream containing 70.0 wt% cancer drug, 27% water (ice), and the balance organic

impurities enters a heated vacuum chamber at a rate of 1000 kg/h at a temperature of -10°C. In the

vacuum chamber, 97% of the water and 99% of the organic impurities in the feed sublime (evaporate)

The dried product is then packaged and shipped. A vapor stream emerges from the chamber at 15'C

During the process, 7.95 x 105 kl/h of heat is transferred to the system.

a)

Draw and label a flowchart of the process.

b)

Calculate the compositions and flow rates of the product and waste streams.

c) Find the temperature of the product stream, using the following values for heat capacity and

heats of sublimation and neglecting the contribution of the organic impurities to the energy

balance.

Cp (ice) 2.11 kl/kg.°C

Cp (water vapour) = 1.86 kJ/kg.°C

Cp (cancer drug) =1.5 kl/kg.°C

AHsubl (water) 2845 kJ/kg

d) Evaporation is a more conventional way to dry wet solids (heating the solid at atmospheric

pressure to a temperature close to the boiling point of the liquid). Give two possible reasons why

freeze drying is a better alternative for many therapeutics such as the cancer drug in the question

(think like biomedical engineers designing a product or process, not necessarily directly related to

material seen in class).

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 8 steps with 6 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The