What is Intermittent?

The term intermittent means something which begins & stops in between at intervals which are not regular.

Intermittent Process

Production system can be defined as process or arrangement which includes performing various functions like collection of inputs, process or reprocessing the inputs & delivering the output or finished goods. The system has three main elements namely inputs, process and output.

Production system can be further divided into two divisions’ namely intermittent process & continuous process.

Meaning of Intermittent Manufacturing Process

Intermittent manufacturing process is a process in which the entire system is made flexible so that a wide variety of products of different sizes or designs can be handled

Which is an Intermittent Process?

Any process which is carried on in a hospital, any general offices or in a machine shop can be considered as an intermittent process.

Intermittent Process

- Intermittent process can be defined as a process in which activities are started & stopped at irregular intervals. Goods under this system are produced on the basis of received customer orders. Goods are generally produced on small scale basis & the manufacturing activities also do not take place continuously & hence it is known as intermittent process. Products created under this process will be of different varieties, design & of different sizes also. Hence this is considered to be a flexible system.

Some of the examples of intermittent process are as follows:

- Catering or any cooking orders received can be an example of intermittent process because food is prepared on the basis of number of people & also the varieties of items will be decided by the customers on the basis of the event or any occasion.

- Performance of a gold smith can be another example in which ornaments are created on the basis of design expectations & requirements of the customers. Also creation of ornaments is not done on a continuous basis.

Features of Intermittent Process

Following are the features of intermittent system:

- Products manufactured are generally of huge varieties.

- Volume produced is generally very small in nature.

- Flow of activities is not continuous & they generally happen only at intervals.

- Elements like quantity, size & design generally are decided on the basis of expectations of the customers.

- A general purpose machine is used for producing different types of products.

- Sequence or frequency of activities keeps varying depending upon the product design.

Categories of Intermittent Processing are as follows

Project production flow: In this category of intermittent processing, a single large order is accepted by the company & it must be completed within a particular time frame at a estimated cost. Under this every product is treated as a project & the activities are sequenced in a series. Techniques like PERT & CPM is used in such products. Examples of projects include construction of roads, bridges, airports etc.

Features of Project Flow are as Follows:

- Requirement of resources will not be the same & it varies with different phases of activities.

- Project timing cannot be estimated & there can be delay at the end of the project.

- Number of agencies is involved in the project & jobs performed are also not related with each other.

- Inspection of the project is required as project programming keeps changing.

Jobbing production flows: Jobbing production flow is another type of intermittent process in which few units of a product are produced as per the design specification of the clients. Products are produced within a given time frame at a fixed cost which is decided when the contract is signed. Examples of such process can include repair shops, manufacturers of special machine tools etc.

- Characteristics of jobbing production are as follows:

- Only skilled labors can perform these kinds of jobs.

- Manufacturing activities take place in batches.

- Goods are produced according to customer expectations.

- Cycle time is not proportionate.

Batch production flows: Assembling activities is scheduled on the basis of specific orders or demand forecasts. Making of goods is done in lots. A product is divided into different jobs & a particular batch is completed before commencing the next batch. Examples of batch creation includes manufacture of medicines, medium & heavy equipment’s etc.

Features of batch activities are as follows:

- Manufactured products are stored until original demand arises.

- Equipment’s & general-purpose machines are used.

- Chances of major work in progress.

- Requirement of a proper plan.

Continuous production system: This is another type of manufacturing process. As the name indicates in this process, activities take place without any break & goods are produced according to forecasted demand. These goods are produced on large basis for the purpose of storage & sale also. These goods are not produced as per the request of the customer.

Examples of Continuous Production System

- Food items are produced in the food industry on a large scale basis & are also based on demand forecast.

- Creation of crude oil & other items in the fuel industry is also on the basis of forecast of demand. Various types of sources are processed continuously to convert fuel into a usable format.

Features of Continuous Production System are

- Products produced are of standard nature

- Processing activities always takes place continuously & not on intervals alone.

- Products are based on pre established standard of quality.

- Manufacturing activities take place against the requirement only.

- Preparation of various types of road maps & schedules.

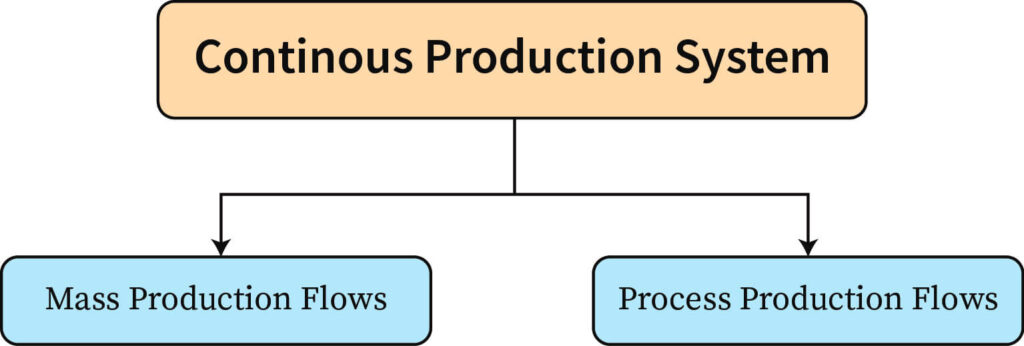

Forms of Continuous Process are as Follows

- Mass production & process production flows.

- Mass production: Huge amount of large scale products are produced & stored in the warehouse until there is demand in the market. Products under this process are created either with a single activity or a group of activities.

- Process production flows is a process in which a single product is manufactured & is stored in warehouse until the same is demanded in the market. Types of products produced under this type are cement, paper, sugar etc. flexibility under this process is very less as only one product is produced at a time.

Context and Applications

This topic is significant in the professional exams for both undergraduate and graduate courses, especially for

- BBA

- MBA

Want more help with your operations management homework?

*Response times may vary by subject and question complexity. Median response time is 34 minutes for paid subscribers and may be longer for promotional offers.

Search. Solve. Succeed!

Study smarter access to millions of step-by step textbook solutions, our Q&A library, and AI powered Math Solver. Plus, you get 30 questions to ask an expert each month.

Intermittent Process Homework Questions from Fellow Students

Browse our recently answered Intermittent Process homework questions.

Search. Solve. Succeed!

Study smarter access to millions of step-by step textbook solutions, our Q&A library, and AI powered Math Solver. Plus, you get 30 questions to ask an expert each month.