What are load and resistance factor designs?

Load and resistance factors design (LRFD), also known as Limit state design (LSD), refers to the design method used in building engineering. A boundary condition is a condition of a structure where it can no longer meet the relevant design requirements. The condition may refer to the load level or other actions on the structure, while the terms refer to the integrity of the structure, suitability for use, durability, or other design requirements. A structure designed for LRFD is limited to keeping track of all possible actions during its design time and is always ready for use, with the appropriate level of reliability in each boundary condition. LRFD-based construction codes clearly define the appropriate levels of reliability in their instructions.

Simplified probabilistic model

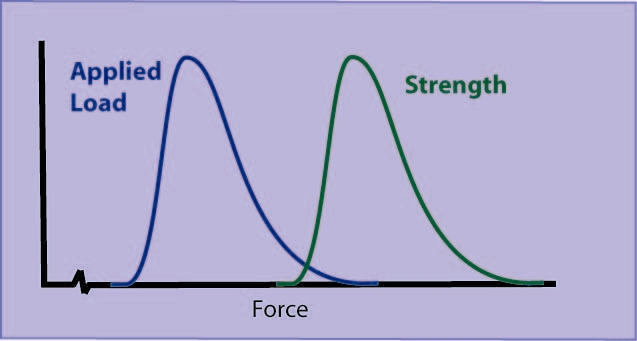

The strength (R) of the structural member and the impact of the load (Q), both parameters are random. Their actual values cannot be determined with certainty. The power of a structure is often referred to as its resistance. It is defined in the popular sense as the higher power a body can have support before failing. Since failure is a term associated with falling in the context of structural behavior. Such limit regions are, for instance, plastic moment, the burden of binding all or part, breaking, fatigue, tremors, and so on. Not all of these conditions are the limiting cause of "collapse". Moreover, it is appropriate to define power as "the boundary condition of a state and using it as the deterministic approach of a structural usefulness."

The structure is satisfactory if Q<R, while instead, Q>R is not acceptable. As Q and R are random, in theory, it is impossible to say with certainty in any structure that Q<R. Even very carefully designed and structural built is small but limits the possibility that Q>R, that is, the boundary condition can be exceeded. Defining a satisfactory architectural design is one of them that reduces this opportunity to an acceptable level. It is possible, by using a simplified method, to measure mathematical boundaries that define the probability of exceeding the limit use as abscissa rate In (R/Q). If In (R/Q)<1, the limit state is skipped, and the shaded areas are opportunities for this event. Since the possible spread of R and Q are not known exactly, the method has always been designed to work only with the definition and standard deviation of random boundaries. This way it is called the First-Order Second-Moment probabilistic analysis.

Reliability Index (β)

According to the first probabilistic method, one can determine the reliability index. So a reliability index can serve as a comparison, a measure of reliability-based between various design methods, types of members, and types of uploads, and is generally recommended to use, there is an opportunity to exceed the limit, in building new LRFD details. The standard reliability-based values are met from 2 to 6, per unit increase corresponding to one order of magnitude reduction in the probability of exceeding the limit condition.

Difference between LRFD and ASD

The main difference between the Allowable stress design (ASD) and Load and resistance factors design (LRFD) is how you can define it and use the safety feature. In simple terms, ASD provides a consistent safety feature across all designs regardless of the type of load, while the LRFD method uses a high level of safety feature is poorly defined loads. The dead load can be calculated correctly so that the LRFD can consider a lower level of safety for them. On the other hand as live loads are less unexpected the LRFD offers a higher security feature to stay on the safe side.

Thus, the LRFD method adjusts the value of the security factor based on the uncertainty of the different methods of failure. As a result, it is usually more economical and efficient.

Standards for LRFD and ASD

American Association of State Highway and Transportation Officials (AASHTO)

Current and revoked AASHTO standards include:

- AASHTO TP10: Typical Testing Method for obtaining grip strength and temperature when breaking a field or laboratory coated with a bituminous mixture by measuring the solid load or load factor on the cooled model at a constant rate while being prevented from overheating.

- AASHTO T307: A Standard Method of Testing the Acquisition of Solid Ground Modulus and Compact Materials.

- AASHTO T321/TP4: A Trial of Recognizing the Tired Health of Compacted Hot-Mix Asphalt (HMA) Under the Repetitive Flexural Curve.

- AASHTO TP31: A General Test Method for Determining the Solid Modulus or load factor of Bituminous Blends by Indirect Pressure

- AASHTO TP62: Standard Test Method to Determine Dynamic Modulus for Hot-Mix Asphalt Concrete Mixtures

- AASHTO T321-03/TP8: Testing Level for Finding Healthy Compacted Compacted Hot-Mix Asphalt (HMA) Under Low Conversely Consensus

The United States is very late in adopting a design for a limited environment (known as LFRD in the US). Design codes and standards are issued by various organizations, some of which have adopted a limited state design, while others have not.

The American Institute of Steel Construction (AISC) 360 Specification of stainless steel structures, American National Standards Institute (ANSI) or American Society of Civil Engineers (ASCE) S-100 specific design for cold stainless steel building design, and the Aluminum Association's Aluminum design manual contains two side design methods.

LRFD, implementation of LSD, and ASD, a method by which the claimed power is divided by a security factor to determine the allowable power. These allowable forces are required to be equal to or exceed the required power of a set of ASD load compounds. ASD is measured to provide the same structural reliability or probability and component size as an LRFD method with resistance factor design and live to dead load. As a result, when structures have a living value of 3 different dead loads, ASD produces less reliable designs, or it does not work very well compared to designs from the LRFD approach.

In contrast, the ANSI D100 welded carbon steel tanks for water storage and the API 650 welded tanks for oil storage still use a valid pressure design.

In the USA building, ASD has not yet been completely eradicated by limited state design except in the case of Suspended bridges, which changed from a stress-free design to limit state formation in the 1960s. Wood, metal, and other materials are still regularly designed using a standard stress design, although the probability of LRFD taught in a USA university program is high.

Context and Applications

This topic is important for professional exams in both graduate and postgraduate studies and in particular:

- Bachelors in Civil Engineering

- Masters in Civil Engineering

Practice Problems

Q1. Which of the following formats is used in the LRFD?

- Multiple safety factors

- Resistance factors

- Load factors

- Elastic factors

Answer: Option a

Explanation: The LRFD or limit state design uses a high-security feature format that is secure enough for high loads and efficient operation in an unloadable load, taking into account all limited conditions.

Q2. Which of the following is a numerator for the factor of safety?

- Deformation stress

- Overload stress

- Ultimate stress

- Resistance stress

Answer: Option c

Explanation: The safety factor is defined as the ratio of ultimate stress to working stress.

Q3. For which of the following design factors of safety design will work best?

- 1

- 2

- 0.5

- 0.8

Answer: Option b

Explanation: For the design factor of safety not more than 1 design will fail.

Q4. On which of the following factors limit state design is based?

- Probability of load factor

- Calculation at un-factored load

- Calculation of load factor or resistance factors

- Calculations at working and ultimate load

Answer: Option d

Explanation: In Load resistance factor design or limit state design, safety at ultimate load and serviceability at working load are considered.

Q5. What type of structures are provided using Load and resistance factors design?

- Inelastic structures

- Reliability-based structures

- Safe structures

- Stressed structures

Answer: Option c

Explanation: Safe structures are provided through the LRFD method.

Want more help with your civil engineering homework?

*Response times may vary by subject and question complexity. Median response time is 34 minutes for paid subscribers and may be longer for promotional offers.

Search. Solve. Succeed!

Study smarter access to millions of step-by step textbook solutions, our Q&A library, and AI powered Math Solver. Plus, you get 30 questions to ask an expert each month.

Load and resistance factor design Homework Questions from Fellow Students

Browse our recently answered Load and resistance factor design homework questions.

Search. Solve. Succeed!

Study smarter access to millions of step-by step textbook solutions, our Q&A library, and AI powered Math Solver. Plus, you get 30 questions to ask an expert each month.