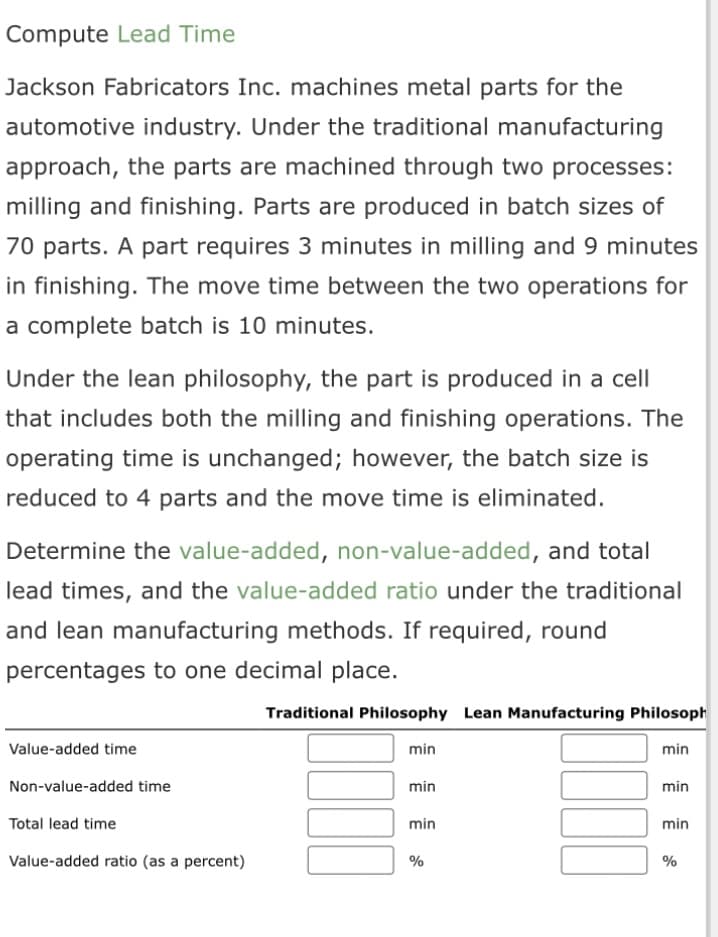

Compute Lead Time Jackson Fabricators Inc. machines metal parts for the automotive industry. Under the traditional manufacturing approach, the parts are machined through two processes: milling and finishing. Parts are produced in batch sizes of 70 parts. A part requires 3 minutes in milling and 9 minutes

Q: A tractor for over-the-road hauling is to be purchased by AgriGrow for $90,000. It is expected to be…

A: Net present value (NPV) is the difference between the present value of cash inflows and the present…

Q: Diamondback Welding & Fabrication Corporation sells and services pipe welding equipment Illinois.…

A: Treasury stock is the stock or shares which are purchased or bought back by the company from the…

Q: EXPLAIN THE EFFECTS OF DIGITAL REVOLUTIONS IN FINANCE ON CORPORATE GOVERNANCE, CORPORATE ACCOUNTING…

A: Digital revolutions in finance, such as the introduction of online banking and mobile payment apps,…

Q: Land acquired for resale or disposal is more appropriately classified as inventory rather than…

A: Assets of a durable type that are utilized by businesses include property, plant, and equipment.…

Q: Greta has risk aversion of A=3 when applied to return on wealth over a one-year horizon. She is…

A: As per the given information: To determine: The Greta's capital allocation.

Q: fund of Company B on January 3, 2021, the following items were found: Currencies ₱…

A: Petty cash fund is used for meeting the office daily expenses and other petty expenses like…

Q: 4. What if November production was 40,000 units, costs were stable, and sales were 41,000 units?…

A: Cost of ending inventory under absorption costing includes the cost of direct materials, direct…

Q: 1. Moneo Co. purchased equipment that was installed and ready for use at the beginning of January…

A: Lets understand the basics. When carrying value of asset is more than recoverable amount then…

Q: The following information was taken from the financial statements of Zeil Inc. for December 31 of…

A: The ratio analysis is done to analyse the different financial statements of the business. The…

Q: The Company's fixed assets as of December 31, 2020 were presented as follows: Class Building…

A: Tangible assets are the resources that a company uses to generate revenue over the multiple future…

Q: Calculate the net present value and profitability index of each project. Of the net present value is…

A: Net Present Value (NPV) is the present worth of the cash flows to be received or paid in the future…

Q: A new customer ABC Ltd, wants to buy 500 units of your product, but is only prepared to pay RM4 per…

A: Corporation - A company is a separate legal entity from its shareholders. Many of the same legal…

Q: What advice to give someone on performing budgetary analysis in their small business

A: While performing the budgetary analysis minutes factors should be considered that involve analysis…

Q: -On January 1, 2021, Bell Company had 2,000,000 shares of common stock outstanding and 60,000 shares…

A: Earnings Per Share (EPS) presents the earnings of firm allocated to each common share outstanding.…

Q: I would like to apply case to prepare profit and loss budget

A: An income statement is a financial report that indicates the revenue and expenses of a business. It…

Q: Laudie Company issued $400,000 of 5%, 10-year bonds on January 1, 2020, at 94. Interest is payable…

A: "Since you have asked multiple questions, we will solve first question for you. If you want any…

Q: TB Problem 10-212 (Static) On January 3, 2024, Michelson... On January 3, 2024, Michelson & Sons…

A:

Q: business has been accounting for its bad A/R using the Allowance Method. For the last 5 years, the…

A: Sales are made by the company and the sales which are made by the company on the credit becomes…

Q: In relation to the 'Six Capitals' listed in the Integrated Reporting Background Paper-Capitals,…

A: The six capitals are: financial, manufactured, human, social and relationship, intellectual, and…

Q: Question 8 If Automated taxes and form setting is on, can you change the date of payment for…

A: Automation allows tax preparers to quickly access the information they need instead of spending…

Q: Presented below are data from the records of Metro Co.…

A: Statement of Cash Flow - Statement of Cash flow show the movement of cash during the financial year.…

Q: How do we end up with the Ending Inventory of $69112 on the budgeted balance sheet?

A: Budgeting - Budgeting is the method of estimating future sales and expenditures to keep control of…

Q: Nowing items: io Company is considering the appropriate classification of the Land held for…

A: Investment property is real estate that a company holds in order to generate rental revenue and/or…

Q: 1. Record the following transactions completed during 20X1 on page 1 of a cash payments journal.…

A: Journal - A business's initial financial transactions are recorded in the journal, which is its…

Q: avier received the following Form 1099-B reporting the sale of 100 shares of stock. How should he…

A: Given in the question: The taxpayers whose name is Xavier Brown has the income from the wages and…

Q: REQUIRED: The business needs to have a sense of its future cash inflows and outflows for the…

A: The cash budget is the estimation of total receipt and payment during the given period. It may be…

Q: Brown Company contracts with Sebastian Company to exchange refrigerated trucks. Brown Company will…

A: An exchange is said to have commercial substance if the risk, timing and amount of cash flows…

Q: Peak Sports has a beginning inventory of 35 snowboards at a cost of $340 each. During the year, the…

A: The term "cost of goods sold" (COGS) refers to the expenses that are incurred directly in the…

Q: Explain the advantages and disadvantages of using ratio analysis to provide guidance to investors…

A: Ratio analysis is a quantitative analysis of data enclosed in an enterprise’s financial statements.…

Q: Break-Even in Sales Revenue, Variable-Costing Ratio, Contribution Margin Ratio, Margin of Safety…

A: Variable cost ratio is the ratio of variable costs to the sales revenue. Contribution margin ratio…

Q: Emerald Corporation is required to change its method of accounting for Federal income tax purposes.…

A: Answer:- Income tax meaning:- Government apply income tax as a sort of tax on the income produced…

Q: Problem 3. In 2013 Bill Barnes and several friends organized a corporation called Barnes…

A: Stockholder's Equity -Stockholder's Equity includes the amount contributed by shareholders issued in…

Q: Which of the following items is not charged against the income of an estate? a. Ordinary repairs…

A: Lets understand the basics. As per basics accounting rules, expense should be charged against the…

Q: Laura, manager of Swifty Company, is using a variable costing system to evaluate the company's…

A: The question has asked to compute the COGS, and, fixed MOH volume variance. Cost of goods sold:…

Q: What is the "Depreciation Expense" and "Accumulated Depreciation for 2020 and 2021 under the…

A: Depreciation Expense is the Wear tear Expense of the usage of the Machine for the Purpose of the…

Q: Blossom Corp. began operations on January 1, 2022, and uses FIFO to cost its inventory. Management…

A: INTRODUCTION: Pretax income, which is also referred to as earnings before taxes or pretax earnings,…

Q: Journalize the company payroll for the semimonthly period ending on August 31. Journalize the…

A: Payroll entry records the payment made to employees and the portion of salary deducted from the…

Q: It is the end of the third quarter, and Margaret is evaluating the performance of two key divisions…

A: East West ROI 0.0575 0.092 RI ($ 26,000) $ 1,000 EVA ($ 64,500) ($ 32,100) Workings:-…

Q: PAS. LO 4.5 Complete the information in the cost computations shown here: Raw Materials Work in…

A: Lets understand the basics. For calculating material available for usage, we need to use below…

Q: Sage Hill Company reports the following costs and expenses in May. Factory utilities Depreciation on…

A: Product costs are the cost involved in the making of the goods. It includes the direct material,…

Q: Goldfarb's Book and Music Store has two service departments, Warehouse and Data Center Warehouse…

A: there are various method that are used for the allocation of the various cause that are charged to…

Q: Varsity Supplies & Things is a family-owned store. The business is now approaching the end of the…

A: A cash budget is an estimate of a corporation's cash flows for a given time span. A cash budget is…

Q: Tutorial Q. 4 Khalid is a salt merchant who supplies salt to general merchants in Lahore city. In…

A: Comment - We’ll answer the first question since the exact one wasn’t specified. Please submit a new…

Q: Schedule of cash payments for a service company Horizon Financial Inc. was organized on February 28.…

A: A schedule for cash payment for selling and administration is a kind of budget prepared to estimate…

Q: A design studio received a loan of $6,750 at 5.80% compounded semi-annually to purchase a camera. If…

A: An amortization plan for a loan shows every periodic payment, including the principal and interest…

Q: If after paying debts and expenses, the estate principal is not adequate to satisfy the various…

A: When there aren't enough shares to divide among a will's heirs, the real estate property is said to…

Q: repare a flexible selling and administrative expenses budget for October for sales volumes of…

A: A flexible budget is a type of budget that shows the total cost at different production levels. It…

Q: units in process, October 31?

A: Costs of the units in process, October 31 will be the equivalents units in process into the cost per…

Q: Problem 1. A company "I aim to get at least 90 out of 100 for this exam" (further in a text as…

A: Bonds are referred to as fixed-income instrument which represents loans made to the issuer and it…

Q: Suppose Hungry Whale Electronics is evaluating a proposed capital budgeting project (project Alpha)…

A: Net present value (NPV) is the difference between the present value of cash inflows and the present…

Trending now

This is a popular solution!

Step by step

Solved in 2 steps

- Calculate lead time Williams Optical Inc. is considering a new lean product cell. The present manufacturing approach produces a product in four separate steps. The production batch sizes are 45 units. The process time for each step is as follows: The time required to move each batch between steps is 5 minutes. In addition, the time to move raw materials to Process Step 1 is also 5 minutes, and the time to move completed units from Process Step 4 to finished goods inventory is 5 minutes. The new lean layout will allow the company to reduce the batch sizes from 45 units to 3 units. The time required to move each batch between steps and the inventory locations will be reduced to 2 minutes. The processing time in each step will stay the same. Determine the value-added, non-value-added, and total lead times, and the value-added ratio under the (A) present and (B) proposed production approaches. (Round percentages to one decimal place.)Use the following information for Exercises 5-44 through 5-46: The following six situations at Diviney Manufacturing Inc. are independent. a. A manual insertion process takes 30 minutes and 8 pounds of material to produce a product. Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is 12, the cost per machine hour is 8, and the cost per pound of materials is 10. b. With its original design, a gear requires 8 hours of setup time. By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%. The cost per setup hour is 50. c. A product currently requires 6 moves. By redesigning the manufacturing layout, the number of moves can be reduced from 6 to 0. The cost per move is 20. d. Inspection time for a plant is 16,000 hours per year. The cost of inspection consists of salaries of 8 inspectors, totaling 320,000. Inspection also uses supplies costing 5 per inspection hour. The company eliminated most defective components by eliminating low-quality suppliers. The number of production errors was reduced dramatically by installing a system of statistical process control. Further quality improvements were realized by redesigning the products, making them easier to manufacture. The net effect was to achieve a close to zero-defect state and eliminate the need for any inspection activity. e. Each unit of a product requires 6 components. The average number of components is 6.5 due to component failure, requiring rework and extra components. Developing relations with the right suppliers and increasing the quality of the purchased component can reduce the average number of components to 6 components per unit. The cost per component is 500. f. A plant produces 100 different electronic products. Each product requires an average of 8 components that are purchased externally. The components are different for each part. By redesigning the products, it is possible to produce the 100 products so that they all have 4 components in common. This will reduce the demand for purchasing, receiving, and paying bills. Estimated savings from the reduced demand are 900,000 per year. 5-44 Nonvalue-Added Costs Refer to the information for Diviney Manufacturing on the previous page. Required: Estimate the nonvalue-added cost for each situation.Use the following information for Exercises 5-44 through 5-46: The following six situations at Diviney Manufacturing Inc. are independent. a. A manual insertion process takes 30 minutes and 8 pounds of material to produce a product. Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is 12, the cost per machine hour is 8, and the cost per pound of materials is 10. b. With its original design, a gear requires 8 hours of setup time. By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%. The cost per setup hour is 50. c. A product currently requires 6 moves. By redesigning the manufacturing layout, the number of moves can be reduced from 6 to 0. The cost per move is 20. d. Inspection time for a plant is 16,000 hours per year. The cost of inspection consists of salaries of 8 inspectors, totaling 320,000. Inspection also uses supplies costing 5 per inspection hour. The company eliminated most defective components by eliminating low-quality suppliers. The number of production errors was reduced dramatically by installing a system of statistical process control. Further quality improvements were realized by redesigning the products, making them easier to manufacture. The net effect was to achieve a close to zero-defect state and eliminate the need for any inspection activity. e. Each unit of a product requires 6 components. The average number of components is 6.5 due to component failure, requiring rework and extra components. Developing relations with the right suppliers and increasing the quality of the purchased component can reduce the average number of components to 6 components per unit. The cost per component is 500. f. A plant produces 100 different electronic products. Each product requires an average of 8 components that are purchased externally. The components are different for each part. By redesigning the products, it is possible to produce the 100 products so that they all have 4 components in common. This will reduce the demand for purchasing, receiving, and paying bills. Estimated savings from the reduced demand are 900,000 per year. 5-45 Driver Analysis Refer to the information for Diviney Manufacturing on the previous page. Required: CONCEPTUAL CONNECTION For each situation, identify the possible root cause(s) of the activity cost (such as plant layout, process design, and product design).

- Mabbut Company has the following departmental manufacturing layout for one of its plants: A consulting firm recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 10 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 10 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Welding is reduced to 6 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 10 units if the cell is in a continuous production mode?Gumbrecht Company has the following departmental manufacturing layout for one of its plants: A consulting firm has recommended a value stream with the following manufacturing cell: Required: 1. Calculate the total time it takes to produce a batch of 20 units using the traditional departmental manufacturing layout. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. Assume the processing time of Casting is reduced to 9 minutes, while the times of the other processes stay the same. What is the production rate now, and how long will it take to produce a batch of 20 units if the cell is in a continuous production mode?Use the following information for Exercises 5-44 through 5-46: The following six situations at Diviney Manufacturing Inc. are independent. a. A manual insertion process takes 30 minutes and 8 pounds of material to produce a product. Automating the insertion process requires 15 minutes of machine time and 7.5 pounds of material. The cost per labor hour is 12, the cost per machine hour is 8, and the cost per pound of materials is 10. b. With its original design, a gear requires 8 hours of setup time. By redesigning the gear so that the number of different grooves needed is reduced by 50%, the setup time is reduced by 75%. The cost per setup hour is 50. c. A product currently requires 6 moves. By redesigning the manufacturing layout, the number of moves can be reduced from 6 to 0. The cost per move is 20. d. Inspection time for a plant is 16,000 hours per year. The cost of inspection consists of salaries of 8 inspectors, totaling 320,000. Inspection also uses supplies costing 5 per inspection hour. The company eliminated most defective components by eliminating low-quality suppliers. The number of production errors was reduced dramatically by installing a system of statistical process control. Further quality improvements were realized by redesigning the products, making them easier to manufacture. The net effect was to achieve a close to zero-defect state and eliminate the need for any inspection activity. e. Each unit of a product requires 6 components. The average number of components is 6.5 due to component failure, requiring rework and extra components. Developing relations with the right suppliers and increasing the quality of the purchased component can reduce the average number of components to 6 components per unit. The cost per component is 500. f. A plant produces 100 different electronic products. Each product requires an average of 8 components that are purchased externally. The components are different for each part. By redesigning the products, it is possible to produce the 100 products so that they all have 4 components in common. This will reduce the demand for purchasing, receiving, and paying bills. Estimated savings from the reduced demand are 900,000 per year. 5-46 Type of Activity Management Refer to the information for Diviney Manufacturing on the previous page. Required: For each situation, identify the cost reduction measure: activity elimination, activity reduction, activity sharing, or activity selection.

- A manufacturing cell within a value stream is structured with four processes and associated processing times (for one unit): Molding: 6 minutes Grinding: 5 minutes Polishing: 5 minutes Finishing: 4 minutes How many units can the cell produce per hour (on a continuous running basis)? a. 3 units per hour b. 12 units per hour c. 15 units per hour d. 10 units per hourEyring Manufacturing produces a component used in its production of washing machines. The time to set up and produce a batch of the components is two days. The average daily usage is 800 components, and the maximum daily usage is 875 components. Required: Compute the reorder point assuming that safety stock is carried by Eyring Manufacturing. How much safety stock is carried by Eyring?A manufacturing cell within a value stream has three processes and the following associated processing times: Drilling: 12 minutes Inserting: 6 minutes Finishing: 2 minutes How many units can the cell produce per hour (on a continuous running basis)? a. 10 units per hour b. 3 units per hour c. 5 units per hour d. 30 units per hour

- Healthway uses a process-costing system to compute the unit costs of the minerals that it produces. It has three departments: Mixing, Tableting, and Bottling. In Mixing, at the beginning of the process all materials are added and the ingredients for the minerals are measured, sifted, and blended together. The mix is transferred out in gallon containers. The Tableting Department takes the powdered mix and places it in capsules. One gallon of powdered mix converts to 1,600 capsules. After the capsules are filled and polished, they are transferred to Bottling where they are placed in bottles, which are then affixed with a safety seal and a lid and labeled. Each bottle receives 50 capsules. During July, the following results are available for the first two departments (direct materials are added at the beginning in both departments): Overhead in both departments is applied as a percentage of direct labor costs. In the Mixing Department, overhead is 200 percent of direct labor. In the Tableting Department, the overhead rate is 150 percent of direct labor. Required: 1. Prepare a production report for the Mixing Department using the weighted average method. Follow the five steps outlined in the chapter. Round unit cost to three decimal places. 2. Prepare a production report for the Tableting Department. Materials are added at the beginning of the process. Follow the five steps outlined in the chapter. Round unit cost to four decimal places.Anderson Company has the following departmental manufacturing structure for one of its products: After some study, the production manager of Anderson recommended the following revised cellular manufacturing approach: Required: 1. Calculate the total time it takes to produce a batch of 20 units using Andersons traditional departmental structure. 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate? 3. What if the processing times of molding, welding, and assembly are all reduced to six minutes each? What is the production rate now, and how long will it take to produce a batch of 20 units?Production run size and activity improvement Littlejohn, Inc., manufactures machined parts for the automotive industry. The activity cost associated with Part XX-10 is as follows: Each unit requires 30 minutes of fabrication direct labor. Moreover, Part XX-10 is manufactured in production run sizes of 50 units. Each production run is set up, scheduled (production control), and moved as a batch of 50 units. Management is considering improvements in the setup, production control, and moving activities in order to cut the production run sizes by half. As a result, the number of setups, production runs, and moves will double from 10 to 20. Such improvements are expected to speed the companys ability to respond to customer orders. Setup is reengineered so that it takes 60% of the original cost per setup. Production control software will allow production control effort and cost per production run to decline by 60%. Moving distance was reduced by 40%, thus reducing the cost per move by the same amount. A. Determine the revised activity cost per unit under the proposed changes. B. Did these improvements reduce the activity cost per unit? C. What cost per unit for setup would be required for the solution in (a) to equal the base solution?