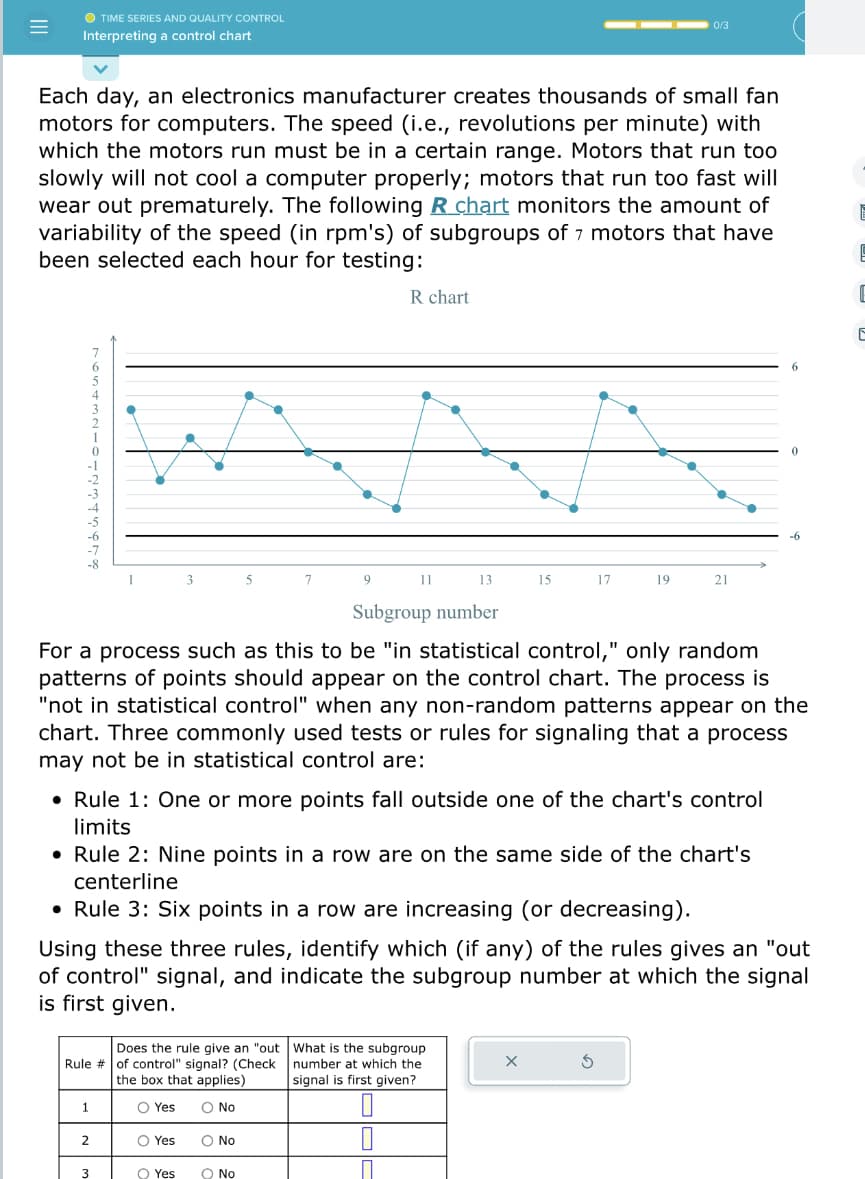

Each day, an electronics manufacturer creates thousands of small fan motors for computers. The speed (i.e., revolutions per minute) with which the motors run must be in a certain range. Motors that run too slowly will not cool a computer properly; motors that run too fast will wear out prematurely. The following R chart monitors the amount of variability of the speed (in rpm's) of subgroups of 7 motors that have been selected each hour for testing: Does the rule give an "out Rule # of control" signal? (Check the box that applies) O Yes O No 1 9 2 R chart O Yes 11 O No 13 Subgroup number For a process such as this to be "in statistical control," only random patterns of points should appear on the control chart. The process is "not in statistical control" when any non-random patterns appear on the chart. Three commonly used tests or rules for signaling that a process may not be in statistical control are: • Rule 1: One or more points fall outside one of the chart's control limits • Rule 2: Nine points in a row are on the same side of the chart's centerline • Rule 3: Six points in a row are increasing (or decreasing). 15 17 Using these three rules, identify which (if any) of the rules gives an "out of control" signal, and indicate the subgroup number at which the signa is first given. What is the subgroup number at which the signal is first given? 0 0 □ 19 21 6

Each day, an electronics manufacturer creates thousands of small fan motors for computers. The speed (i.e., revolutions per minute) with which the motors run must be in a certain range. Motors that run too slowly will not cool a computer properly; motors that run too fast will wear out prematurely. The following R chart monitors the amount of variability of the speed (in rpm's) of subgroups of 7 motors that have been selected each hour for testing: Does the rule give an "out Rule # of control" signal? (Check the box that applies) O Yes O No 1 9 2 R chart O Yes 11 O No 13 Subgroup number For a process such as this to be "in statistical control," only random patterns of points should appear on the control chart. The process is "not in statistical control" when any non-random patterns appear on the chart. Three commonly used tests or rules for signaling that a process may not be in statistical control are: • Rule 1: One or more points fall outside one of the chart's control limits • Rule 2: Nine points in a row are on the same side of the chart's centerline • Rule 3: Six points in a row are increasing (or decreasing). 15 17 Using these three rules, identify which (if any) of the rules gives an "out of control" signal, and indicate the subgroup number at which the signa is first given. What is the subgroup number at which the signal is first given? 0 0 □ 19 21 6

Holt Mcdougal Larson Pre-algebra: Student Edition 2012

1st Edition

ISBN:9780547587776

Author:HOLT MCDOUGAL

Publisher:HOLT MCDOUGAL

Chapter7: Percents

Section7.2: Percents And Proportions

Problem 18E

Related questions

Question

Transcribed Image Text:=

OTIME SERIES AND QUALITY CONTROL

Interpreting a control chart

Each day, an electronics manufacturer creates thousands of small fan

motors for computers. The speed (i.e., revolutions per minute) with

which the motors run must be in a certain range. Motors that run too

slowly will not cool a computer properly; motors that run too fast will

wear out prematurely. The following R chart monitors the amount of

variability of the speed (in rpm's) of subgroups of 7 motors that have

been selected each hour for testing:

1

1

3

Does the rule give an "out

Rule # of control" signal? (Check

the box that applies)

O Yes

O No

2

3

O Yes

7

Yes

9

R chart

O No

11

• Rule 1: One or more points fall outside one of the chart's control

limits

O No

• Rule 2: Nine points in a row are on the same side of the chart's

centerline

• Rule 3: Six points in a row are increasing (or decreasing).

13

Subgroup number

For a process such as this to be "in statistical control," only random

patterns of points should appear on the control chart. The process is

"not in statistical control" when any non-random patterns appear on the

chart. Three commonly used tests or rules for signaling that a process

may not be in statistical control are:

15

Using these three rules, identify which (if any) of the rules gives an "out

of control" signal, and indicate the subgroup number at which the signal

is first given.

What is the subgroup

number at which the

signal is first given?

17

0/3

19

X

21

S

6

0

-6

E

E

E

Transcribed Image Text:TIME SERIES AND QUALITY CONTROL

Interpreting a control chart

QUYUTION

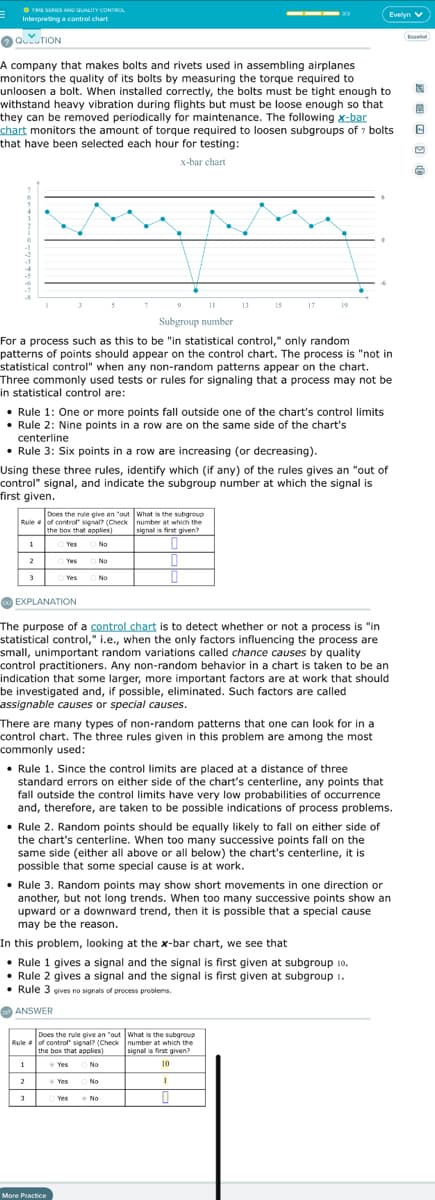

A company that makes bolts and rivets used in assembling airplanes

monitors the quality of its bolts by measuring the torque required to

unloosen a bolt. When installed correctly, the bolts must be tight enough to

withstand heavy vibration during flights but must be loose enough so that

they can be removed periodically for maintenance. The following x-bar

chart monitors the amount of torque required to loosen subgroups of 7 bolts

that have been selected each hour for testing:

x-bar chart

Does the rule give an "out

Rule of control signal? (Check

the box that applies)

Yes

No

No

No

For a process such as this to be "in statistical control," only random

patterns of points should appear on the control chart. The process is "not in

statistical control" when any non-random patterns appear on the chart.

Three commonly used tests or rules for signaling that a process may not be

in statistical control are:

• Rule 1: One or more points fall outside one of the chart's control limits

• Rule 2: Nine points in a row are on the same side of the chart's

centerline

• Rule 3: Six points in a row are increasing (or decreasing).

1

2

Using these three rules, identify which (if any) of the rules gives an "out of

control" signal, and indicate the subgroup number at which the signal is

first given.

Yes

Ⓒ Yes

11

Subgroup number

1

EXPLANATION

The purpose of a control chart is to detect whether or not a process is "in

statistical control," i.e., when the only factors influencing the process are

small, unimportant random variations called chance causes by quality

control practitioners. Any non-random behavior in a chart is taken to be an

indication that some larger, more important factors are at work that should

be investigated and, if possible, eliminated. Such factors are called

assignable causes or special causes.

Does the rule give an "out

Rule of control signal? (Check

the box that applies)

Yes

No

Yes

2

There are many types of non-random patterns that one can look for in a

control chart. The three rules given in this problem are among the most

commonly used:

3

13

What is the subgroup

number at which the

signal is first given?

15

• Rule 1. Since the control limits are placed at a distance of three

standard errors on either side of the chart's centerline, any points that

fall outside the control limits have very low probabilities of occurrence

and, therefore, are taken to be possible indications of process problems.

• Rule 2. Random points should be equally likely to fall on either side of

the chart's centerline. When too many successive points fall on the

same side (either all above or all below) the chart's centerline, it is

possible that some special cause is at work.

More Practice

17

19

• Rule 3. Random points may show short movements in one direction or

another, but not long trends. When too many successive points show an

upward or a downward trend, then it is possible that a special cause

may be the reason.

In this problem, looking at the x-bar chart, we see that

• Rule gives a signal and the signal is first given at subgroup 10.

Rule 2 gives a signal and the signal is first given at subgroup 1.

Rule 3 gives no signals of process problems.

ANSWER

Yes

No

No

What is the subgroup

number at which the

signal is first given?

10

Evelyn V

1

U

9

8

6

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps

Recommended textbooks for you

Holt Mcdougal Larson Pre-algebra: Student Edition…

Algebra

ISBN:

9780547587776

Author:

HOLT MCDOUGAL

Publisher:

HOLT MCDOUGAL

Mathematics For Machine Technology

Advanced Math

ISBN:

9781337798310

Author:

Peterson, John.

Publisher:

Cengage Learning,

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning

Holt Mcdougal Larson Pre-algebra: Student Edition…

Algebra

ISBN:

9780547587776

Author:

HOLT MCDOUGAL

Publisher:

HOLT MCDOUGAL

Mathematics For Machine Technology

Advanced Math

ISBN:

9781337798310

Author:

Peterson, John.

Publisher:

Cengage Learning,

College Algebra (MindTap Course List)

Algebra

ISBN:

9781305652231

Author:

R. David Gustafson, Jeff Hughes

Publisher:

Cengage Learning