Hart Manufacturing makes three products. Each product requires manufacturing operations in three departments: A, B, and C. The labor-hour requirements, by department, are as follows. Department Product 1 s.t. A B C 1.50 2.00 0.25 Product 2 Product 3 3.00 1.00 0.25 2.00 ✓ 2.50 During the next production period, the labor-hours available are 450 in department A, 350 in department B, and 50 in department C. The profit contributions per unit are $25 for product 1, $27 for product 2, and $28 for product 3. (a) Formulate a linear programming model for maximizing total profit contribution. (Let P, = units of product i produced, for i = 1, 2, 3.) Max 25P₁ +27P2+28P3 0.25 Department A 1.50P₁ +3.00P2 +2.00P3 ≤450 Department B 2.00P₁ +1.00P₂ +2.50P ≤350 2 Department c 0.25P₁+0.25P₂ +0.25P3 ≤ 50 P₁, P₂, P3 20 (b) Solve the linear program formulated in part (a). How much of each product should be produced, and what is the projected total profit contribution (in dollars)? (P1, P2, P3): 60,80,60 with profit $ 5340 (c) After evaluating the solution obtained in part (b), one of the production supervisors noted that production setup costs had not been taken into account. She noted that setup costs are $400 for product 1, $590 for product 2, and $610 for product 3. If the solution developed in part (b) is to be used, what is the total profit contribution (in dollars) after taking into account the setup costs? $ 3740

Hart Manufacturing makes three products. Each product requires manufacturing operations in three departments: A, B, and C. The labor-hour requirements, by department, are as follows. Department Product 1 s.t. A B C 1.50 2.00 0.25 Product 2 Product 3 3.00 1.00 0.25 2.00 ✓ 2.50 During the next production period, the labor-hours available are 450 in department A, 350 in department B, and 50 in department C. The profit contributions per unit are $25 for product 1, $27 for product 2, and $28 for product 3. (a) Formulate a linear programming model for maximizing total profit contribution. (Let P, = units of product i produced, for i = 1, 2, 3.) Max 25P₁ +27P2+28P3 0.25 Department A 1.50P₁ +3.00P2 +2.00P3 ≤450 Department B 2.00P₁ +1.00P₂ +2.50P ≤350 2 Department c 0.25P₁+0.25P₂ +0.25P3 ≤ 50 P₁, P₂, P3 20 (b) Solve the linear program formulated in part (a). How much of each product should be produced, and what is the projected total profit contribution (in dollars)? (P1, P2, P3): 60,80,60 with profit $ 5340 (c) After evaluating the solution obtained in part (b), one of the production supervisors noted that production setup costs had not been taken into account. She noted that setup costs are $400 for product 1, $590 for product 2, and $610 for product 3. If the solution developed in part (b) is to be used, what is the total profit contribution (in dollars) after taking into account the setup costs? $ 3740

Practical Management Science

6th Edition

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:WINSTON, Wayne L.

Chapter8: Evolutionary Solver: An Alternative Optimization Procedure

Section: Chapter Questions

Problem 23P

Related questions

Question

I just need clear solutions and answers for part D and part E please

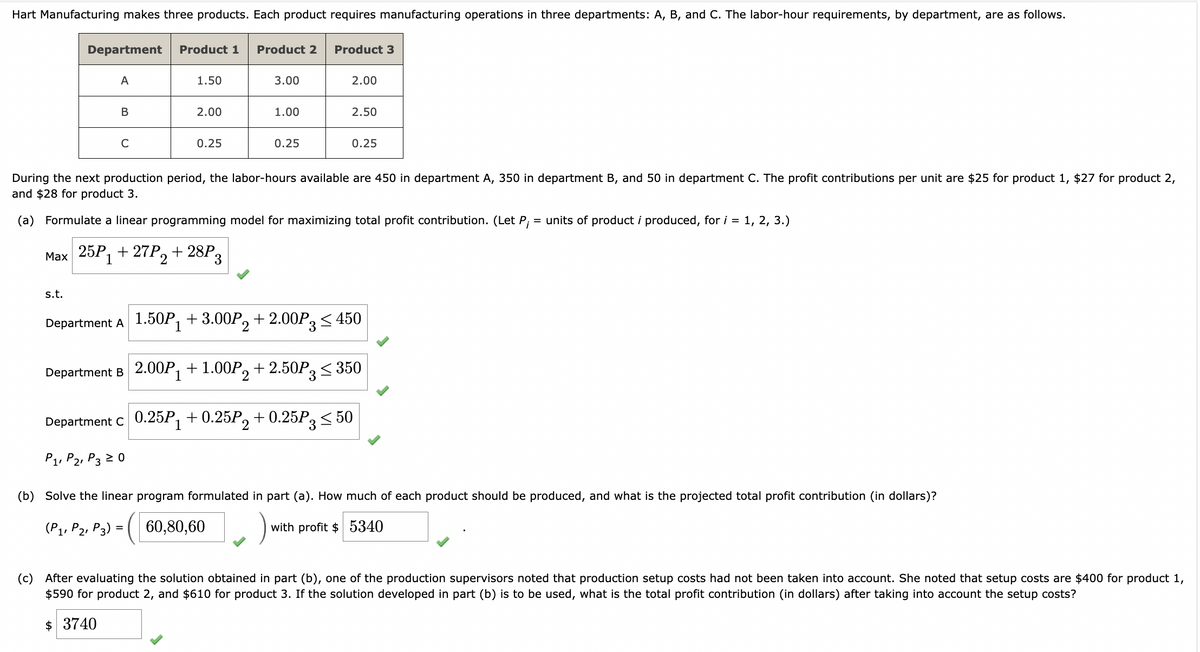

Transcribed Image Text:Hart Manufacturing makes three products. Each product requires manufacturing operations in three departments: A, B, and C. The labor-hour requirements, by department, are as follows.

Department Product 1

s.t.

A

B

C

1.50

2.00

0.25

Product 2 Product 3

3.00

1.00

0.25

2.00

2.50

0.25

During the next production period, the labor-hours available are 450 in department A, 350 in department B, and 50 in department C. The profit contributions per unit are $25 for product 1, $27 for product 2,

and $28 for product 3.

(a) Formulate a linear programming model for maximizing total profit contribution. (Let P; = units of product i produced, for i = 1, 2, 3.)

Max 25P₁+27P2+28P 3

Department A 1.50P₁ +3.00P2 +2.00P3 ≤ 450

Department B 2.00P₁ +1.00P2 +2.50P3 ≤ 350

Department c 0.25P₁ +0.25P2 +0.25P3 ≤ 50

P₁, P2, P3 ≥ 0

(b) Solve the linear program formulated in part (a). How much of each product should be produced, and what is the projected total profit contribution (in dollars)?

(P₁, P2, P3) = 60,80,60

with profit $ 5340

(c) After evaluating the solution obtained in part (b), one of the production supervisors noted that production setup costs had not been taken into account. She noted that setup costs are $400 for product 1,

$590 for product 2, and $610 for product 3. If the solution developed in part (b) is to be used, what is the total profit contribution (in dollars) after taking into account the setup costs?

$ 3740

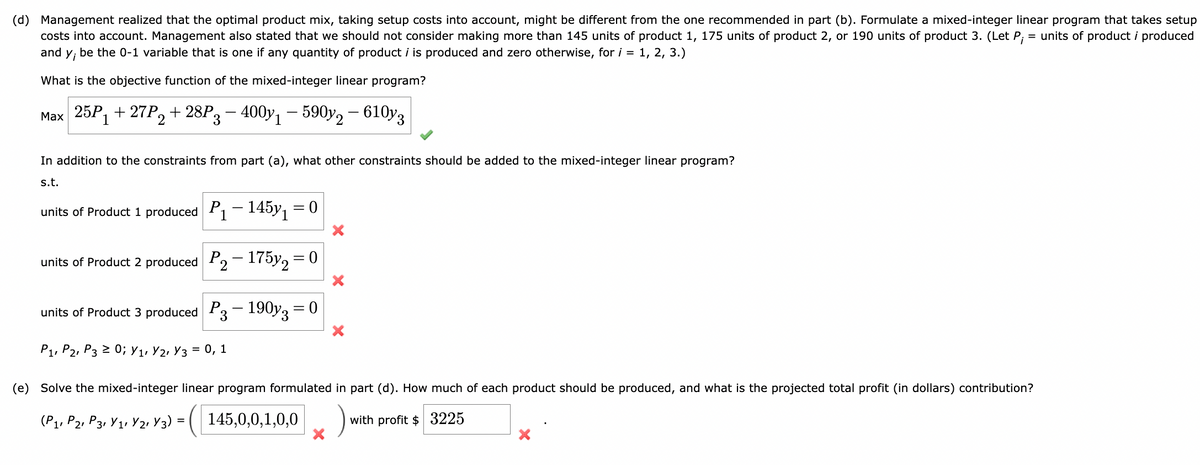

Transcribed Image Text:(d) Management realized that the optimal product mix, taking setup costs into account, might be different from the one recommended in part (b). Formulate a mixed-integer linear program that takes setup

costs into account. Management also stated that we should not consider making more than 145 units of product 1, 175 units of product 2, or 190 units of product 3. (Let P₁ = units of product i produced

and

Y₁ be the 0-1 variable that is one if any quantity of product i is produced and zero otherwise, for i = 1, 2, 3.)

What is the objective function of the mixed-integer linear program?

Max 25P₁+27P2+28P 3 - 4001 - 590y2 - 610y3

In addition to the constraints from part (a), what other constraints should be added to the mixed-integer linear program?

s.t.

units of Product 1 produced P₁-145y₁ = 0

units of Product 2 produced

P2-175y2 = 0

units of Product 3 produced

P3-190y3 = 0

P1, P2, P3 ≥ 0; V₁, V2, V3 = 0, 1

X

(e) Solve the mixed-integer linear program formulated in part (d). How much of each product should be produced, and what is the projected total profit (in dollars) contribution?

with profit $ 3225

(P₁, P2, P3, V₁, V2, Y3) = ( 145,0,0,1,0,0 )

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 3 steps with 4 images

Recommended textbooks for you

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,

Practical Management Science

Operations Management

ISBN:

9781337406659

Author:

WINSTON, Wayne L.

Publisher:

Cengage,