Problem 30-4E. The "spinning disk" reactor is often used to carry out chemical reactions under controlled hydrodynamic conditions. Consider the highly-simplified process shown in Figure 30-4E, where one spinning disk is mounted within a chamber equipped a single gas inlet and outlet stream. The surface of the disk is coated with a non-porous catalyst. The catalyst surface catalyzes an instantaneous reaction where gaseous reactant A goes to gaseous product B (A →B on the surface). Since the reaction is presumed instantaneous, the rate process is mass transfer limited, and the concentration of A at the catalyst surface is essentially zero (CAS≈ 0). As the disk spins, a hydrodynamic boundary layer is created between the surface and the bulk gas, and the spinning motion also mixes the bulk gas to create a well-mixed environment within the chamber. The process is carried out at 600 K and 2.0 atm, where 20 cm³/sec of feed gas (also at conditions of 600 K and 2.0 atm) containing 5.0 mole % of reactant A and 95 mole% of inert carrier gas C are delivered to the chamber. The diameter of the disk is 10 cm, and the volume of the chamber is 2000 cm³. Potentially relevant properties for A, B, and C are provided below: Selected properties of gaseous species A, B, and C at T = 600 K and P = 2.0 atm. molecular diffusion coefficient DAC = 0.300 cm²/sec kinematic viscosity VA = 0.520 cm²/sec DBC = 0.235 cm²/sec VB = 0.300 cm2²/sec DAB=0.219 cm²/sec Vc = 0.520 cm²/sec (a) A mass transfer coefficient of ke = 1.345 cm/sec for reactant A in the gas mixture is desired. What is the required spinning disk rotation rate, oo, in units of rev/sec? Is the mass-transfer process for reactant A within the boundary layer best described as a dilute unimolecular diffusion process (UMD) process, or an equimolar counter-diffusion (EMCD) process? Justify your reasoning. (b) Develop a steady-state process material balance model, in fully algebraic form (no numbers), to predict the outlet concentration, CA. (c) Determine the outlet concentration, CA, based on kc = 1.345 cm/sec. If the natation of the dial in i which of the fallami

Problem 30-4E. The "spinning disk" reactor is often used to carry out chemical reactions under controlled hydrodynamic conditions. Consider the highly-simplified process shown in Figure 30-4E, where one spinning disk is mounted within a chamber equipped a single gas inlet and outlet stream. The surface of the disk is coated with a non-porous catalyst. The catalyst surface catalyzes an instantaneous reaction where gaseous reactant A goes to gaseous product B (A →B on the surface). Since the reaction is presumed instantaneous, the rate process is mass transfer limited, and the concentration of A at the catalyst surface is essentially zero (CAS≈ 0). As the disk spins, a hydrodynamic boundary layer is created between the surface and the bulk gas, and the spinning motion also mixes the bulk gas to create a well-mixed environment within the chamber. The process is carried out at 600 K and 2.0 atm, where 20 cm³/sec of feed gas (also at conditions of 600 K and 2.0 atm) containing 5.0 mole % of reactant A and 95 mole% of inert carrier gas C are delivered to the chamber. The diameter of the disk is 10 cm, and the volume of the chamber is 2000 cm³. Potentially relevant properties for A, B, and C are provided below: Selected properties of gaseous species A, B, and C at T = 600 K and P = 2.0 atm. molecular diffusion coefficient DAC = 0.300 cm²/sec kinematic viscosity VA = 0.520 cm²/sec DBC = 0.235 cm²/sec VB = 0.300 cm2²/sec DAB=0.219 cm²/sec Vc = 0.520 cm²/sec (a) A mass transfer coefficient of ke = 1.345 cm/sec for reactant A in the gas mixture is desired. What is the required spinning disk rotation rate, oo, in units of rev/sec? Is the mass-transfer process for reactant A within the boundary layer best described as a dilute unimolecular diffusion process (UMD) process, or an equimolar counter-diffusion (EMCD) process? Justify your reasoning. (b) Develop a steady-state process material balance model, in fully algebraic form (no numbers), to predict the outlet concentration, CA. (c) Determine the outlet concentration, CA, based on kc = 1.345 cm/sec. If the natation of the dial in i which of the fallami

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

Transcribed Image Text:Problem 30-4E. The "spinning disk" reactor is often used to carry out chemical reactions under

controlled hydrodynamic conditions. Consider the highly-simplified process shown in Figure 30-4E,

where one spinning disk is mounted within a chamber equipped a single gas inlet and outlet stream. The

surface of the disk is coated with a non-porous catalyst. The catalyst surface catalyzes an instantaneous

reaction where gaseous reactant A goes to gaseous product B (A →B on the surface). Since the reaction

is presumed instantaneous, the rate process is mass transfer limited, and the concentration of A at the

catalyst surface is essentially zero (CAS≈ 0). As the disk spins, a hydrodynamic boundary layer is

created between the surface and the bulk gas, and the spinning motion also mixes the bulk gas to create a

well-mixed environment within the chamber. The process is carried out at 600 K and 2.0 atm, where 20

cm³/sec of feed gas (also at conditions of 600 K and 2.0 atm) containing 5.0 mole% of reactant A and 95

mole% of inert carrier gas C are delivered to the chamber. The diameter of the disk is 10 cm, and the

volume of the chamber is 2000 cm³. Potentially relevant properties for A, B, and C are provided below:

Selected properties of gaseous species A, B, and C at T = 600 K and P = 2.0 atm.

molecular diffusion coefficient DAC = 0.300 cm²/sec

kinematic viscosity

VA = 0.520 cm²/sec

DBC = 0.235 cm²/sec

VB = 0.300 cm²/sec

DAB = 0.219 cm²/sec

Vc = 0.520 cm²/sec

(a) A mass transfer coefficient of ke = 1.345 cm/sec for reactant A in the gas mixture is desired. What is

the required spinning disk rotation rate, co, in units of rev/sec? Is the mass-transfer process for

reactant A within the boundary layer best described as a dilute unimolecular diffusion process (UMD)

process, or an equimolar counter-diffusion (EMCD) process? Justify your reasoning.

(b) Develop a steady-state process material balance model, in fully algebraic form (no numbers), to

predict the outlet concentration, CA.

(c) Determine the outlet concentration, CA, based on kc = 1.345 cm/sec.

(d) If the rotation rate (o) of the disk is increased, which of the following process variables will also

increase in value? Select all that apply, and justify your choice for each.

(1) ke

(2) CA at outlet (3) NA

(e) If the volumetric flowrate Vo is increased, which of the following process variables will also increase

in value? Select all that apply, and justify your choice for each

(1) ke

(2) CA at outlet

(3) NA

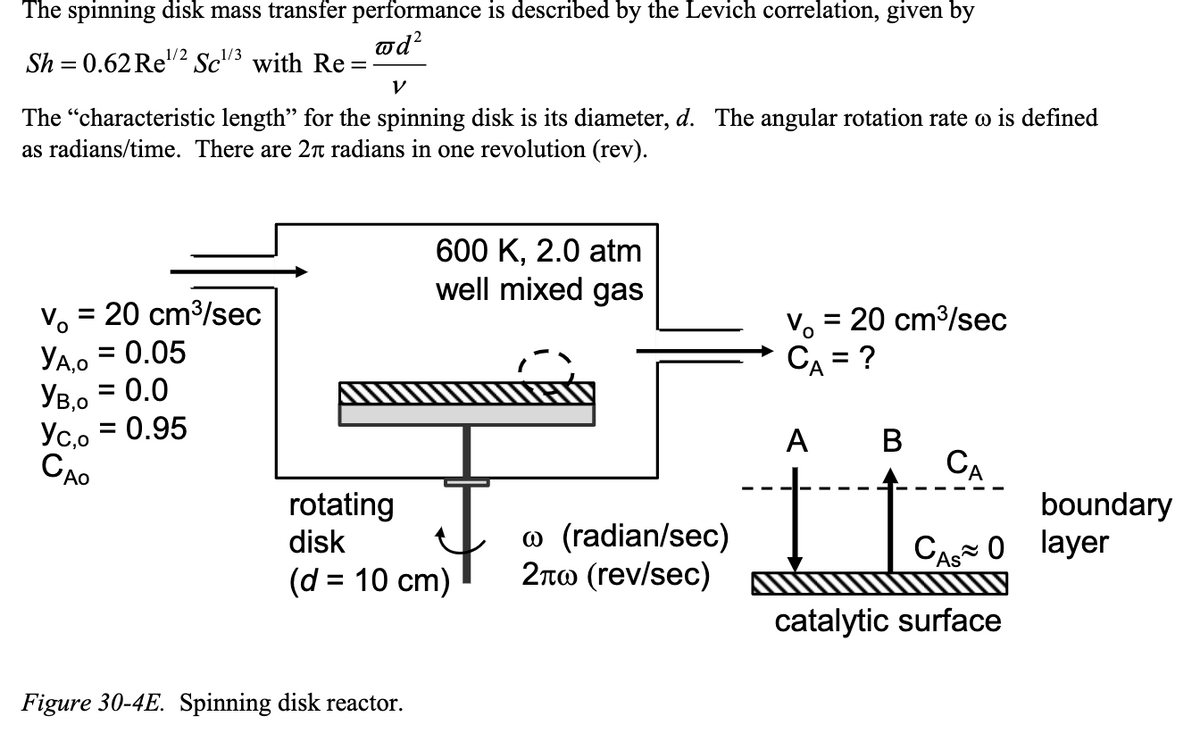

Transcribed Image Text:The spinning disk mass transfer performance is described by the Levich correlation, given by

@d²

Sh = 0.62 Re¹/2 Sc¹/3 with Re=

V

The "characteristic length" for the spinning disk is its diameter, d. The angular rotation rate o is defined

as radians/time. There are 2 radians in one revolution (rev).

V₁ = = 20 cm³/sec

YA,O = 0.05

Ув,0 = 0.0

Yc,o= 0.95

CAO

600 K, 2.0 atm

well mixed gas

rotating

disk

(d = 10 cm)

Figure 30-4E. Spinning disk reactor.

(radian/sec)

2л (rev/sec)

V₁ = 20 cm³/sec

CA = ?

А

A B

CA

I love

CA 0

catalytic surface

boundary

layer

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

This is a popular solution!

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 7 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The